Automatic homogenization equipment for building construction

A building construction and automatic technology, applied in construction, building construction, clay preparation devices, etc., can solve the problems of low construction efficiency and rely on labor, and achieve the effect of improving construction efficiency, reducing work steps and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

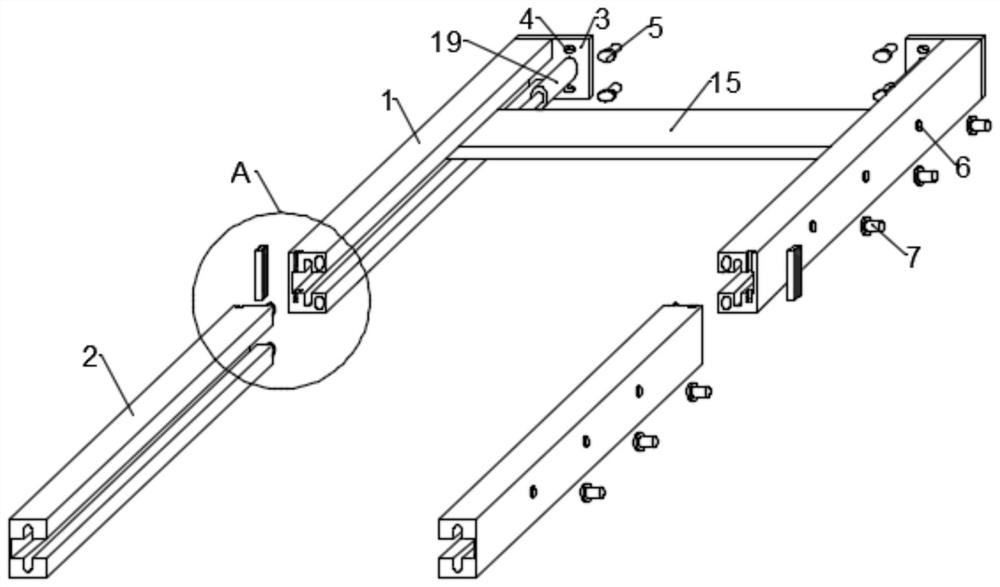

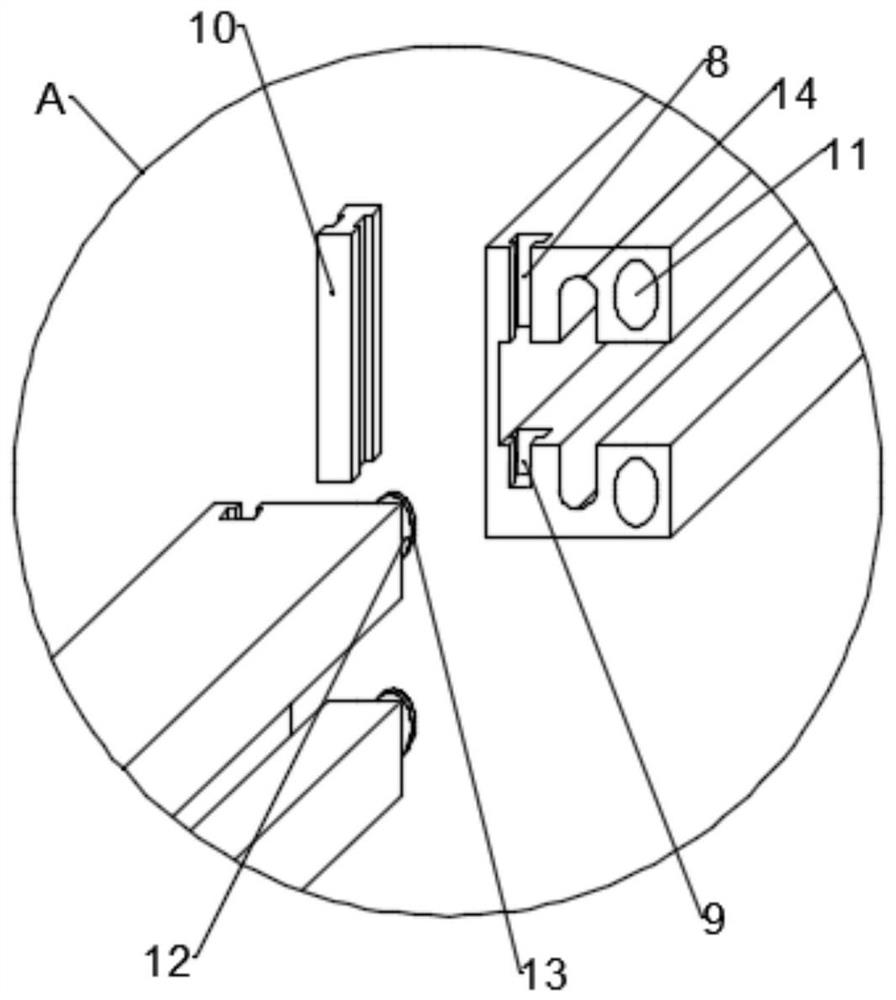

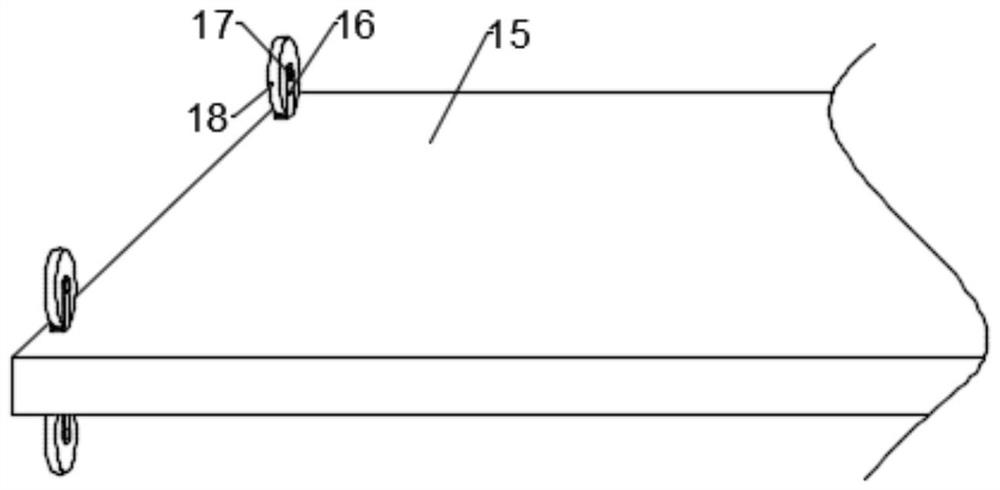

[0038] Such as figure 1 and Figure 4 As shown, the embodiment of the present invention provides an automatic homogenizing equipment for building construction, the automatic homogenizing equipment includes two left and right symmetrical fixing mechanisms, and the mounting plate 15 is movably installed in the two fixing mechanisms through the sliding mechanism; The fixing mechanism includes a first fixing plate 1 and a second fixing plate 2, which are connected through a connecting assembly and a positioning assembly between the first fixing plate 1 and the second fixing plate 2; the lower surface of the mounting plate 15 is installed There is an automatic mortar blanking mechanism, and a stirring assembly is installed on the upper surface of the mounting plate 15, and the stirring assembly is connected with the automatic mortar blanking mechanism; an automatic leveling mechanism is installed on the rear side of the automatic mortar blanking mechanism.

[0039] The automatic h...

Embodiment 2

[0055] Such as Figure 4~5 As shown, in yet another embodiment provided by the present invention, the stirring assembly includes a mixing box 20, the upper side wall of the mixing box 20 is provided with a feeding port 21, and the top of the mixing box 20 is connected to There is a top cover 22; a motor 23 is installed on the top of the top cover 22, and the output end of the motor 23 is driven and connected with a rotating shaft 24 through a coupling, and a straight rod stirring paddle 25 and a spiral scraper are fixed on the rotating shaft 24 plate 26 ; the straight-rod stirring paddle 25 is located inside the spiral scraper 26 , and the spiral scraper 26 is in contact with the inner wall of the mixing box 20 .

[0056] Open the top cover 22, put the raw materials into the mixing box 20, use the feed port 21 to feed the feed, start the motor 23, and the motor 23 drives the rotating shaft 24 to rotate, thereby driving the straight rod stirring paddle 25 and the spiral scraper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com