Feeding and discharging device applied to automatic wafer box packaging equipment

A technology of packaging equipment and wafer cassettes, applied in the field of automation, can solve the problems of misplacement and leakage, low efficiency of manual operation, misplacement and leaking, and achieves the effect of liberating manpower, facilitating maintenance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

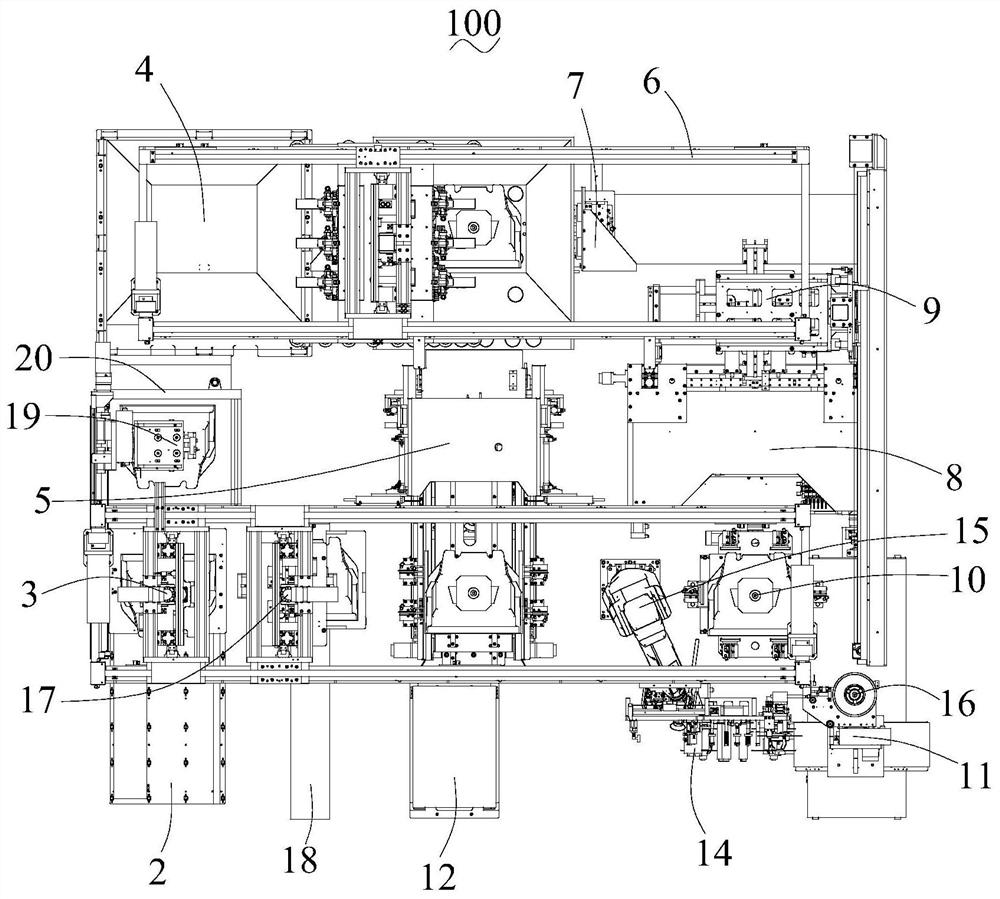

[0035] Please refer to Figure 1 to Figure 22 , a wafer cassette automatic packaging equipment 100, including a complete machine frame (not shown) and a feeding platform 2 installed on the complete machine frame, a first handling device 3, a packaging bag storage box 4, a bag-in Module 5, bag taking device 6, packaging platform 7, sealing module 8, third handling device 9, shaping rotary platform 10, shaping module 11, label printer 12, label reel 13, tearing label module 14, sticking A label robot 15, a tape roll release mechanism 16, a second transport device 17, and a discharge platform 18.

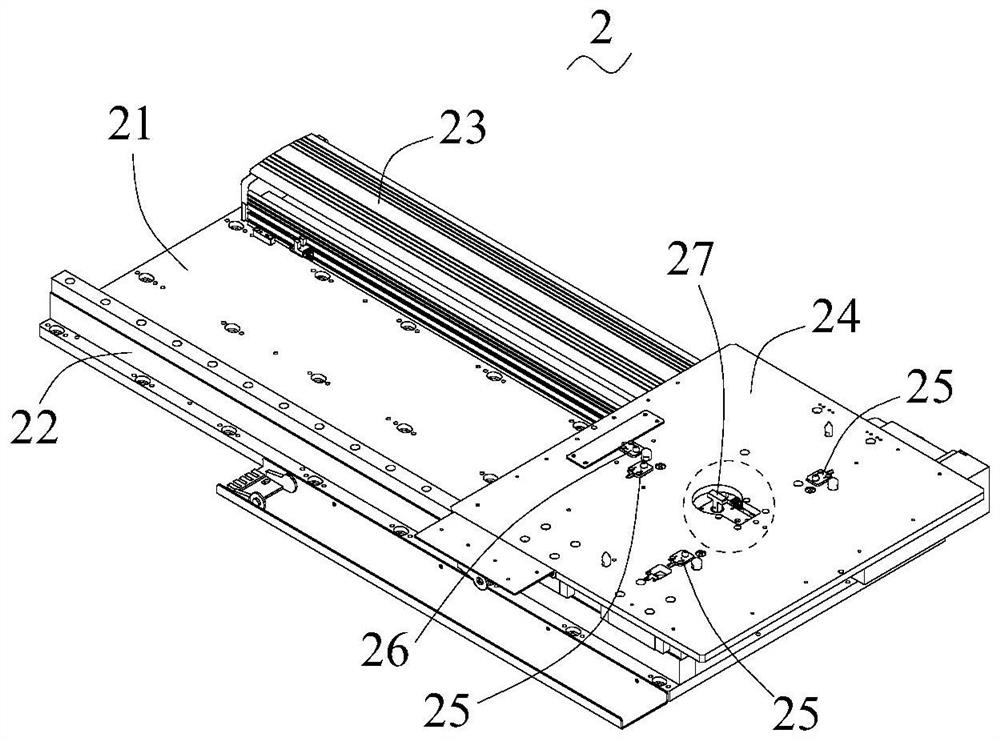

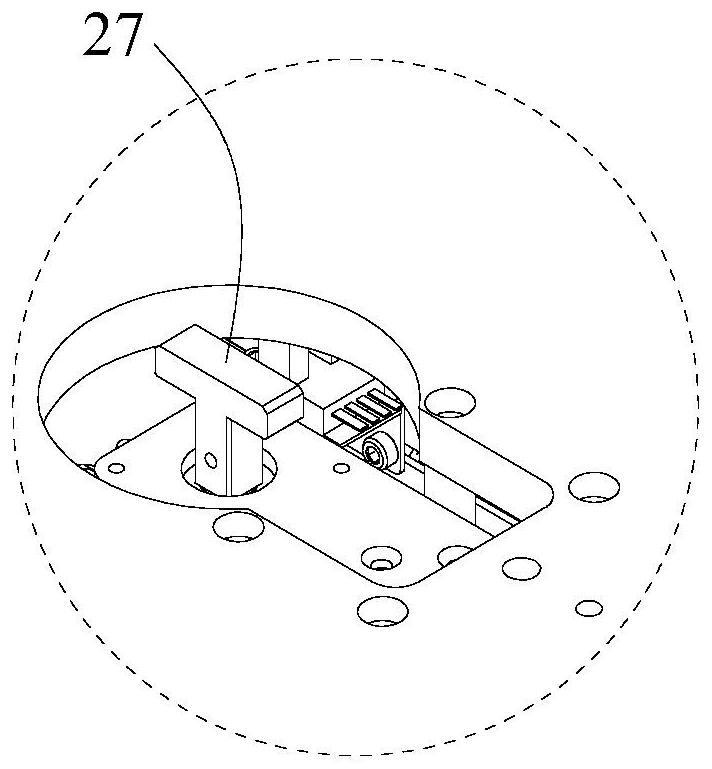

[0036] Please refer to figure 2 , the feeding platform 2 positions the wafer cassette 200 after the wafer cassette 200 is placed in an accurate position. The structure of the feeding platform 2 is: including a bottom plate 21 , a rail 22 , a first linear module 23 , a first placement platform 24 , a position detection sensor 25 , a product information identification sensor 26 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com