Powdery emulsion explosive mineral additive surface modification method

A mineral additive, powder emulsion explosive technology, applied in explosive processing equipment, chemical instruments and methods, non-explosive/non-thermal agent components, etc. It is easy to be damaged by friction and other problems, so as to achieve the effect of not easy to clean, improve compatibility and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

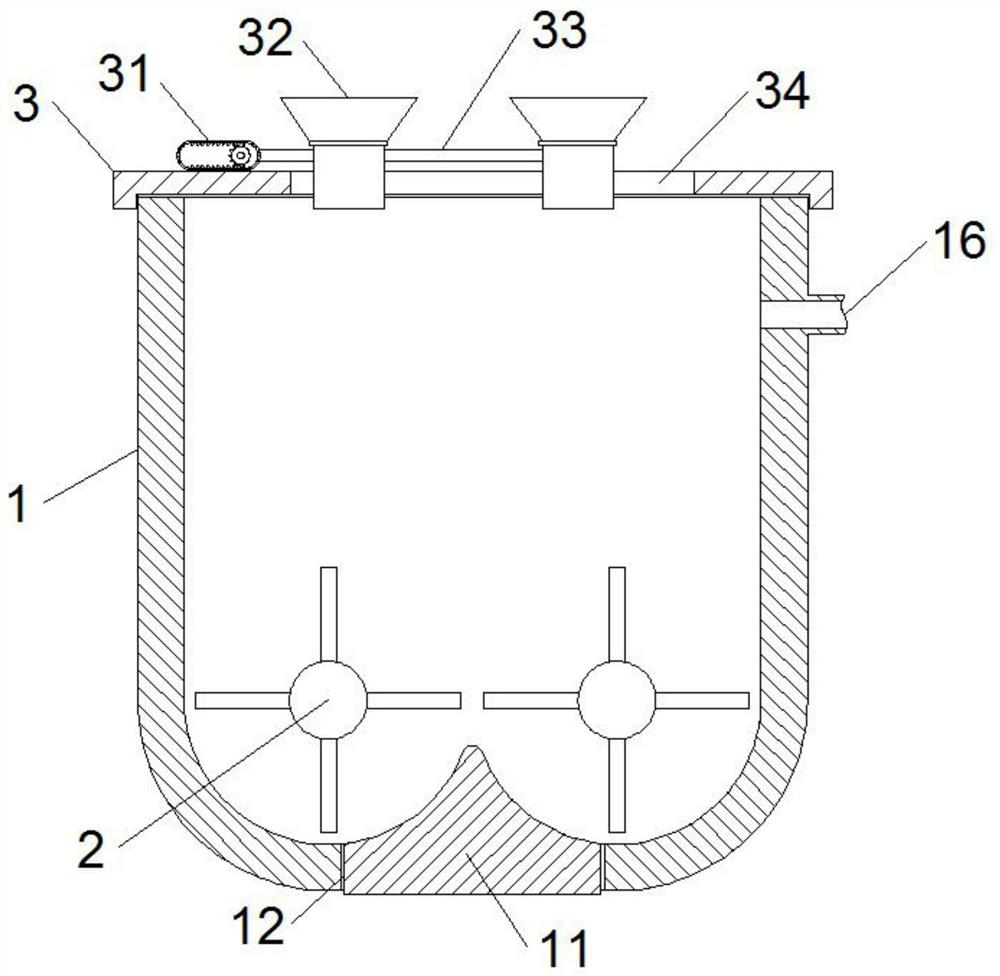

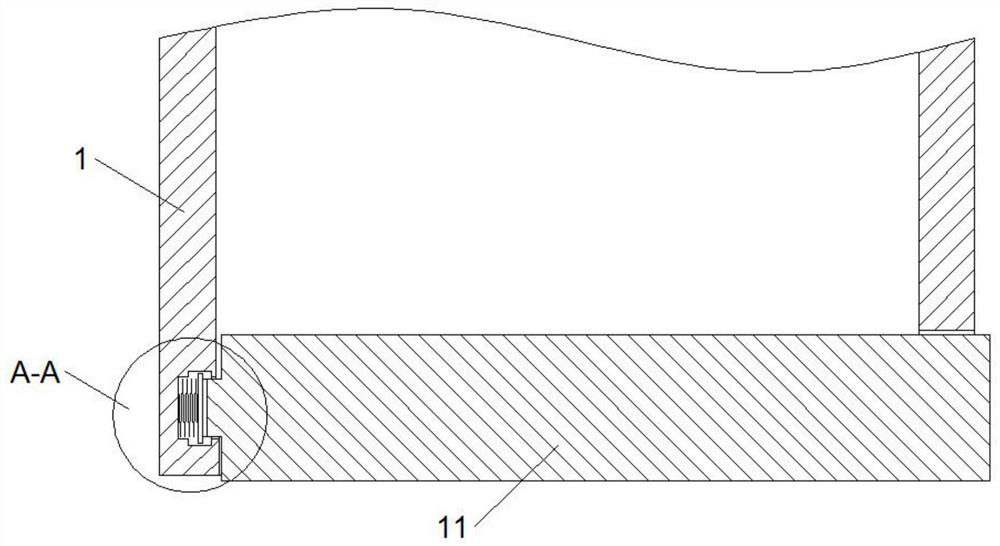

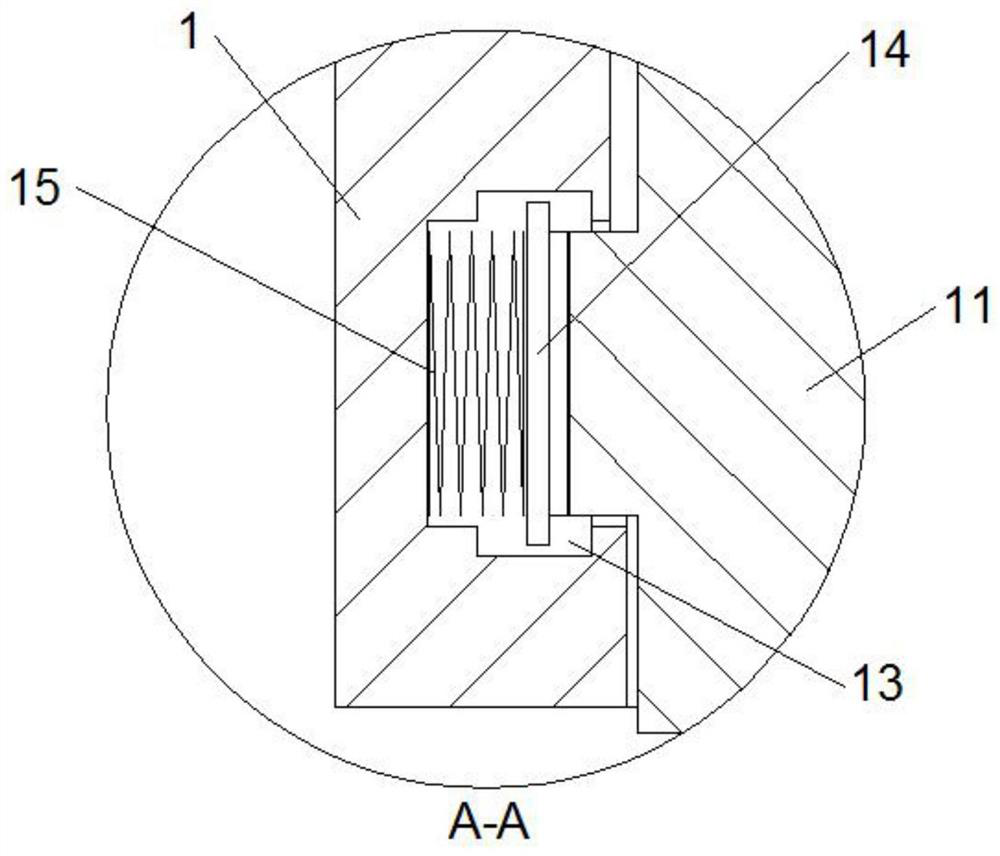

Image

Examples

Embodiment 1

[0035] A method for surface modification of mineral additives in powdered emulsion explosives. The specific method steps are as follows:

[0036] S1: Heating: Heat the paraffin wax to a flowable molten state, and at the same time heat the 40 mesh talc powder to the same temperature as the molten paraffin wax, the heating temperature is 60°C, and the mass ratio of paraffin wax to talc powder is 1: 100;

[0037] S2: mixing: mixing the molten paraffin wax heated in step S1 and the heated mineral powder in a mixing device;

[0038] S3: Cooling and packaging: After stirring and mixing until the paraffin completely coats the mineral powder, cool to room temperature to obtain the modified mineral, which is packaged for later use;

[0039] S4: Charge: mix a certain proportion of modified minerals and naked explosive powder, and charge them in a 32mm paper roll after mixing. The weight of the charge is 170g, and the length of the charge is 220mm. The explosive performance of the explosive is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com