Master batch for resin

A masterbatch and resin technology, applied in the coating and other directions, can solve the problems of easy deformation, deformation of the masterbatch, affecting the use value of the masterbatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

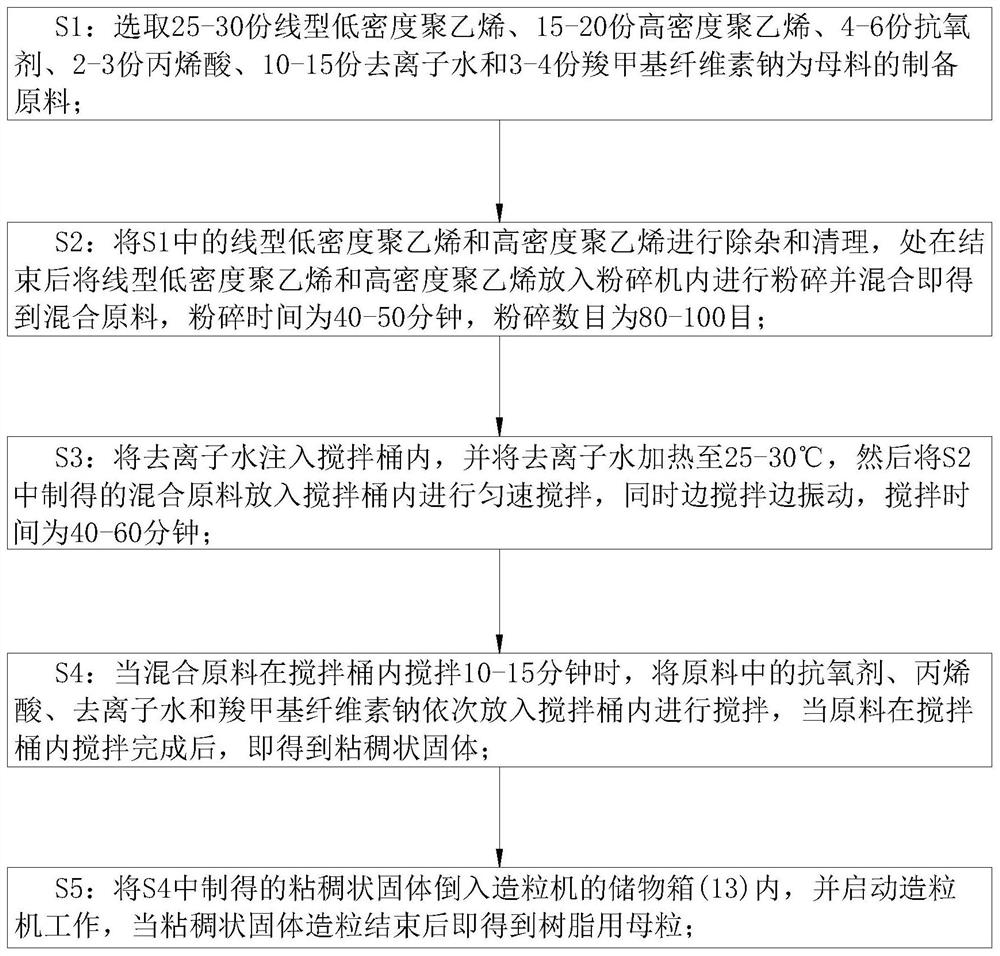

Method used

Image

Examples

Embodiment approach

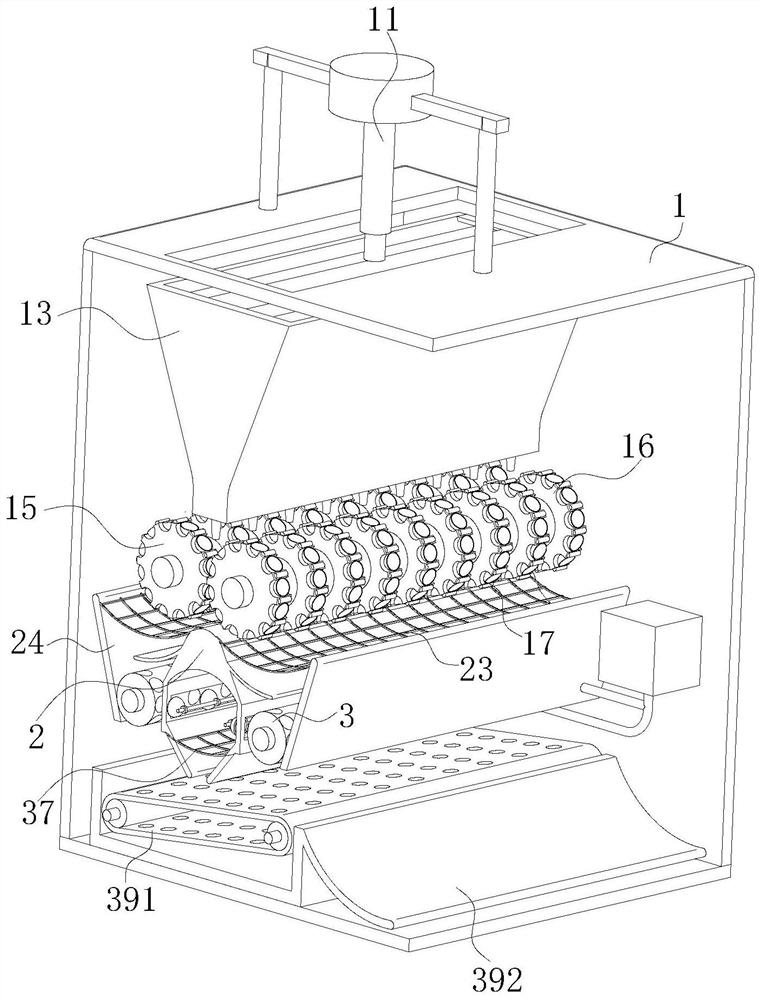

[0053] As an embodiment of the present invention, uniformly arranged through holes 393 are opened in the inner wall of the collection belt 391, and the diameter of the through holes 393 is smaller than the diameter of the masterbatch;

[0054] During work, because the through-hole 393 of uniform arrangement is opened in the inner wall of collection belt 391, and the diameter of through-hole 393 is smaller than the diameter of particle, in the process that collection belt 391 rotates, the particle that falls on the collection belt 391 can fall into through-hole 393, the particles are moved to the collecting plate 392 by following the rotation of the through hole 393. During this process, the particles can be prevented from rolling on the collecting belt 391, thereby preventing the particles from deforming the master batch during the long-term rolling process.

[0055] The specific workflow is as follows:

[0056] During work, when using the granulator made by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com