Three-dimensional light fiber embedded composite yarn and preparation method

A lightweight fiber and embedded technology, applied in the field of textile yarn, can solve the problems of unsatisfactory spinnability, poor cohesion, small fineness, etc., and achieve good spinnability, not easy to depilate, and good warmth retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

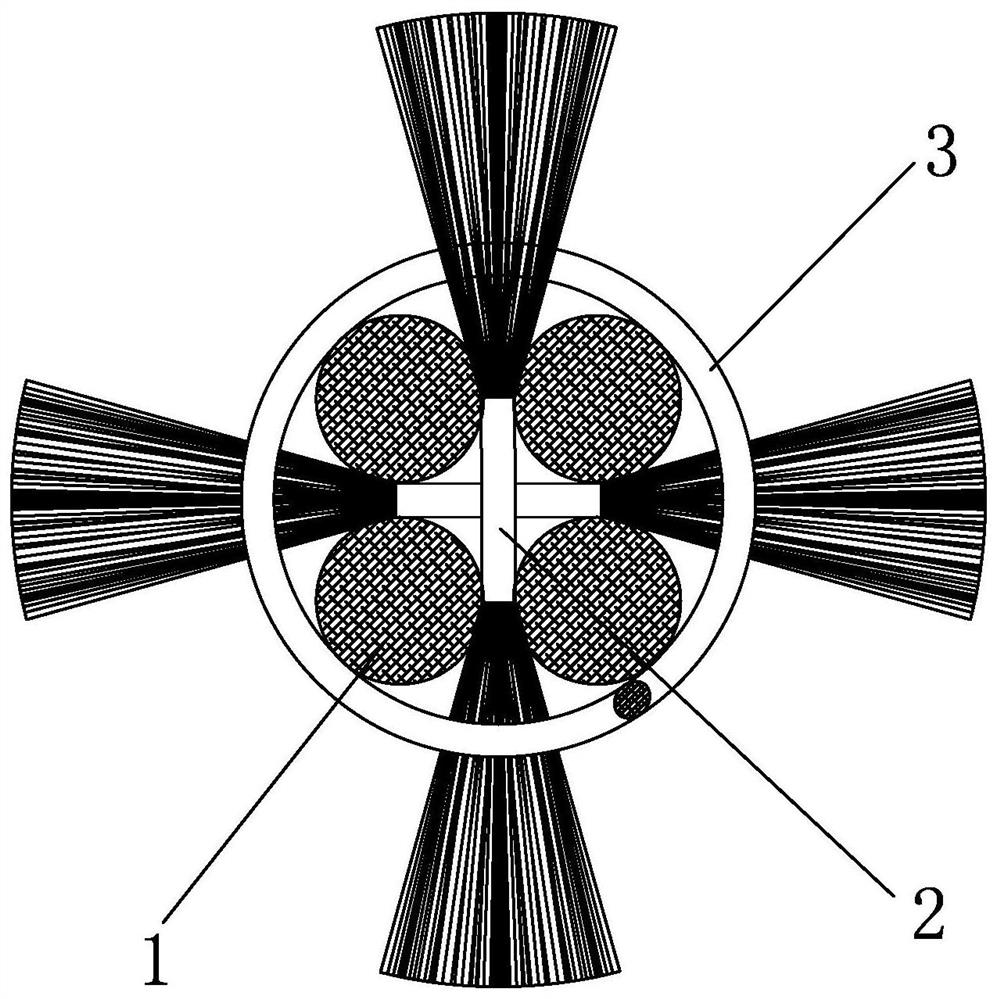

[0020] combine figure 1 , the invention discloses a three-dimensional lightweight fiber-embedded composite yarn, which adopts a composite single yarn structure and includes a yarn body. The yarn body includes core yarn 1, lightweight fiber bundle 2 and wrapping yarn 3. Usually, during the yarn forming process of the yarn body, the lightweight fiber bundle 2 is embedded into the yarn body to form a composite yarn with a three-dimensional structure. The composite yarn can give full play to the excellent characteristics of the light fiber, solve the spinnability problem of the light fiber, and is not easy to depilate. There are 4 core yarns 1 distributed in a square shape. The four core yarns 1 are symmetrically arranged with the center of the yarn body as the axis of symmetry, and are helically wound and plyed along the length direction of the yarn body. The light fiber bundle 2 is made of light short fibers parallel and bundled without twisting. Preferably, the lightweight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com