Creel three-jacquard jacquard screen cloth and manufacturing method

A production method and creel technology, which is applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems of simple mesh, lack of change, and difficulty in changing the face of creel warp-knitted mesh, and achieve the effect of enriching the mesh , Rich mesh diversity, better three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

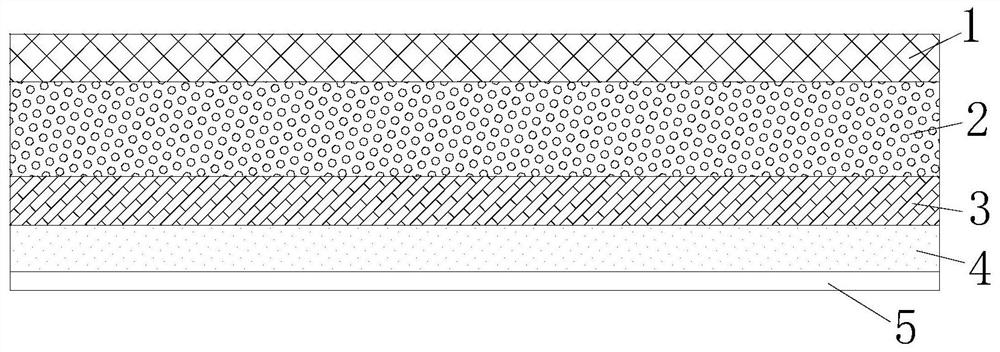

[0036] According to the composition of the double-sided mesh yarn layer, the creel three jacquard mesh fabric is divided into: mesh jacquard surface layer 1, creel skeleton layer 2, pattern jacquard layer 3, and bottom layer 5.

[0037] The manufacturing method of creel three jacquard jacquard mesh fabric is to use a double needle bed warp knitting machine for integrated knitting, and the double needle bed warp knitting machine is provided with bar JB1, bar JB2, bar JB3, bar JB4, bar Comb JB5, comb JB6, comb GB8.

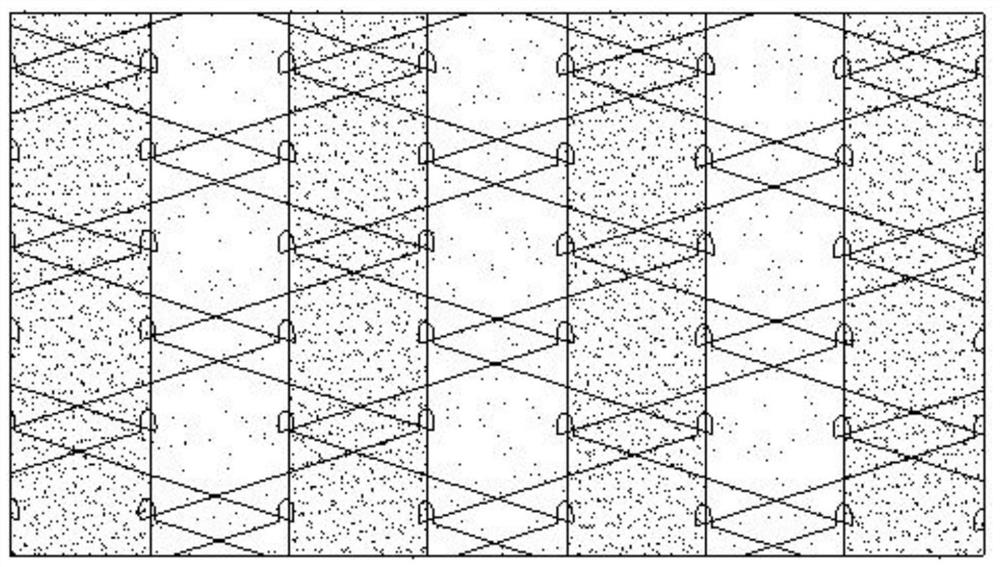

[0038] Mesh jacquard surface layer 1

[0039] Jacquard 1: Including two separate, half gauge Jacquard bars JB1 and JB2;

[0040] Bar JB1: Warping 200D polyester low-elasticity yarn with 6 pan heads and 256 yarns in each pan head. JB1 yarn threading on the machine is 1 thread and 1 empty. Gear let-off is 2300mm / lack, JB1 Warp plain weave 1-0 / 1-1 / 1-2 / 1-1 / / , JB1 polyester low elastic yarn content accounts for about 12.366%.

[0041] Bar JB2: Warping 200D polyester l...

Embodiment 2

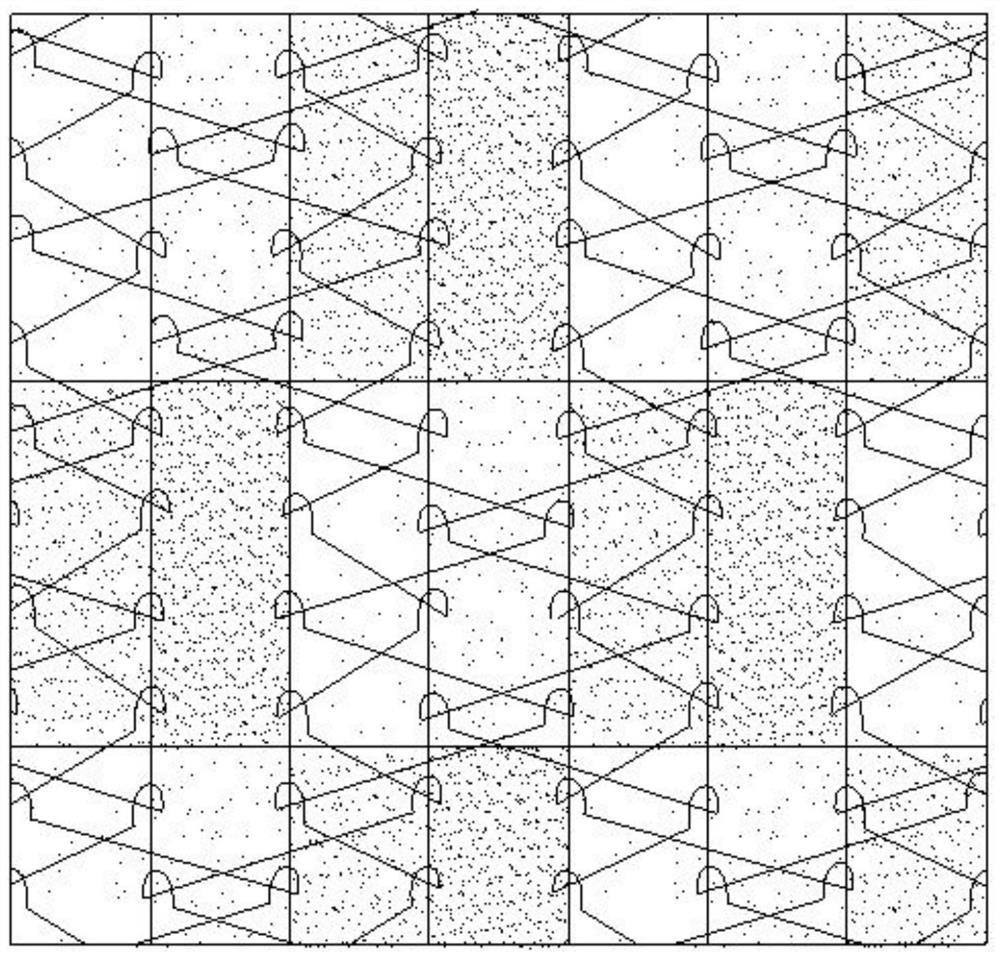

[0054] Such as image 3 As shown, the creel three jacquard mesh fabric is divided into double-sided mesh fabric yarn layer composition: mesh jacquard surface layer 1, creel skeleton layer 2, pattern jacquard layer 3, wool top layer 4, and bottom layer 5.

[0055] Such as Figure 4 As shown, the manufacturing method of creel three jacquard jacquard mesh is to use a double needle bed warp knitting machine for integrated knitting, and the double needle bed warp knitting machine is sequentially provided with bar JB1, bar JB2, bar JB3, bar JB4, comb JB5, comb JB6, comb JB7, comb GB8.

[0056] Mesh jacquard surface layer 1

[0057] Jacquard 1: Including two separate, half gauge Jacquard bars JB1 and JB2;

[0058] Bar JB1: Warping 200D polyester low-elasticity yarn with 6 pan heads and 256 yarns in each pan head. JB1 yarn threading on the machine is 1 thread and 1 empty. Gear let-off is 2300mm / lack, JB1 Warp plain weave 1-0 / 1-1 / 1-2 / 1-1 / / , JB1 polyester low elastic yarn content ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com