Construction method of high-altitude vertical manned passage in high-mountain rock area

A construction method, alpine rock technology, applied in the direction of bridge parts, erection/assembly bridges, bridges, etc., can solve the problems that cannot be popularized and applied, the height of erection is limited, and the risk factor is high, so as to achieve the effect of energy saving and environmental protection, shorten the construction period, reduce mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A construction method for a high-altitude vertical manned passageway in an alpine rock area, comprising:

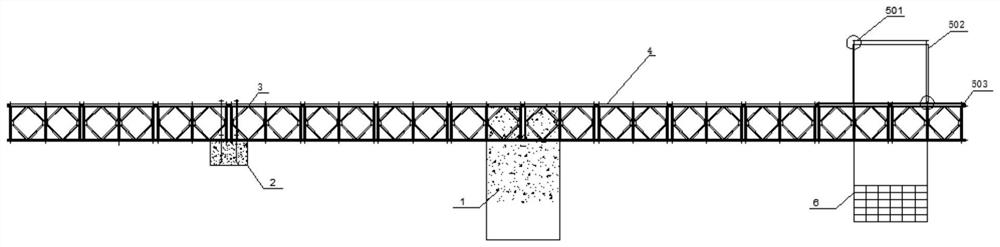

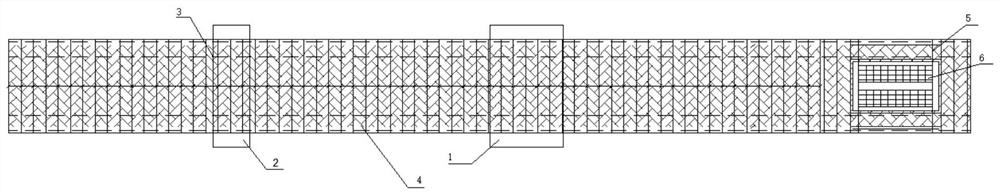

[0035] S1, set the front fulcrum 1 close to the cliff, the rear fulcrum 2 away from the cliff, the front fulcrum 1 and the rear fulcrum 2 are formed by pouring concrete; excavate the foundation of the front fulcrum 1 and the rear fulcrum 2; the front fulcrum 1 and the excavation slope ratio of the rear fulcrum 2 are both 1:1, and the bottom of the corresponding fulcrum is excavated until it falls on the complete rock surface; concrete is poured with a combined steel formwork, and the front fulcrum 1 and the rear fulcrum are obtained after curing to the design strength. fulcrum 2;

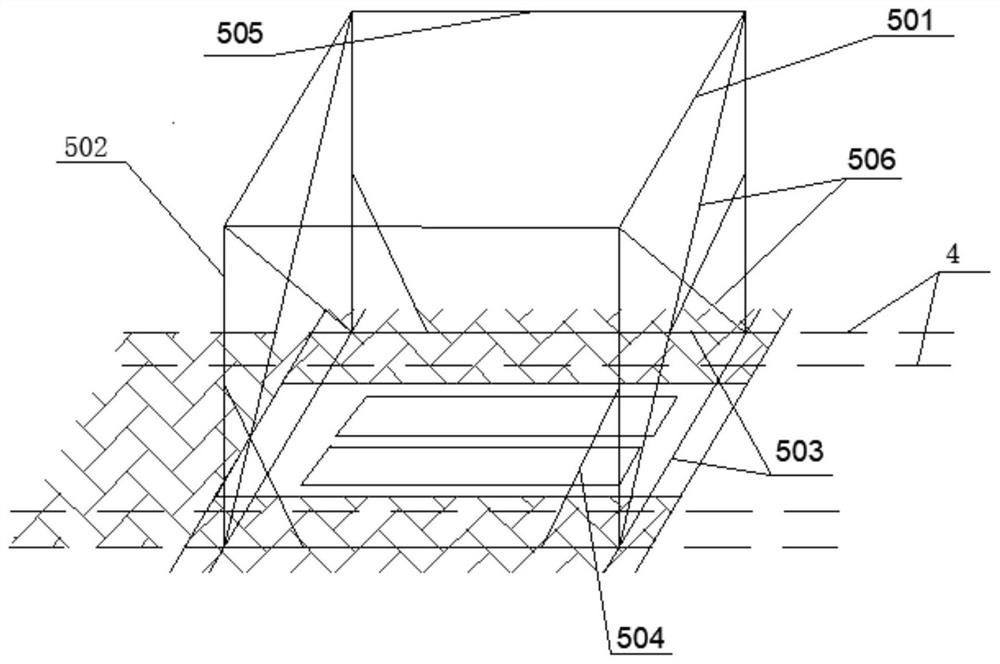

[0036]S2. There is a rear anchor embedded part on the rear fulcrum 2; splicing the double fulcrum Bailey beam 3 as the main body, and assembling the Bailey beam from the front fulcrum 1 to the rear fulcrum 2, here from the front fulcrum 1 to the rear fulcrum 2 The splicing is the splici...

Embodiment 2

[0041] A construction method for a high-altitude vertical manned passageway in an alpine rock area, comprising:

[0042] S1, set the front fulcrum 1 close to the cliff, the rear fulcrum 2 away from the cliff, the front fulcrum 1 and the rear fulcrum 2 are formed by pouring concrete; excavate the foundation of the front fulcrum 1 and the rear fulcrum 2; the front fulcrum 1 and the excavation slope ratio of the rear fulcrum 2 are both 1:1, and the bottom of the corresponding fulcrum is excavated until it falls on the complete rock surface; concrete is poured with a combined steel formwork, and the front fulcrum 1 and the rear fulcrum are obtained after curing to the design strength. fulcrum 2;

[0043] S2. There is a rear anchor embedded part on the rear fulcrum 2; splicing the double fulcrum Bailey beam 3 as the main body, and assembling the Bailey beam from the front fulcrum 1 to the rear fulcrum 2, here from the front fulcrum 1 to the rear fulcrum 2 The splicing is the splic...

Embodiment 3

[0052] A construction method for a high-altitude vertical manned passageway in an alpine rock area, comprising:

[0053] S1, set the front fulcrum 1 close to the cliff, the rear fulcrum 2 away from the cliff, the front fulcrum 1 and the rear fulcrum 2 are formed by pouring concrete; excavate the foundation of the front fulcrum 1 and the rear fulcrum 2; the front fulcrum 1 and the excavation slope ratio of the rear fulcrum 2 are both 1:1, and the bottom of the corresponding fulcrum is excavated until it falls on the complete rock surface; concrete is poured with a combined steel formwork, and the front fulcrum 1 and the rear fulcrum are obtained after curing to the design strength. fulcrum 2;

[0054] S2. There is a rear anchor embedded part on the rear fulcrum 2; splicing the double fulcrum Bailey beam 3 as the main body, and assembling the Bailey beam from the front fulcrum 1 to the rear fulcrum 2, here from the front fulcrum 1 to the rear fulcrum 2 The splicing is the splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com