Lift valve centering device

A technology of centering device and poppet valve, which is applied to valve devices, lift valves, engine components, etc., can solve the problem of difficulty in ensuring the coaxiality of poppet valves, and achieves improved processing and manufacturing efficiency and assembly rate, high assembly rate, and structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

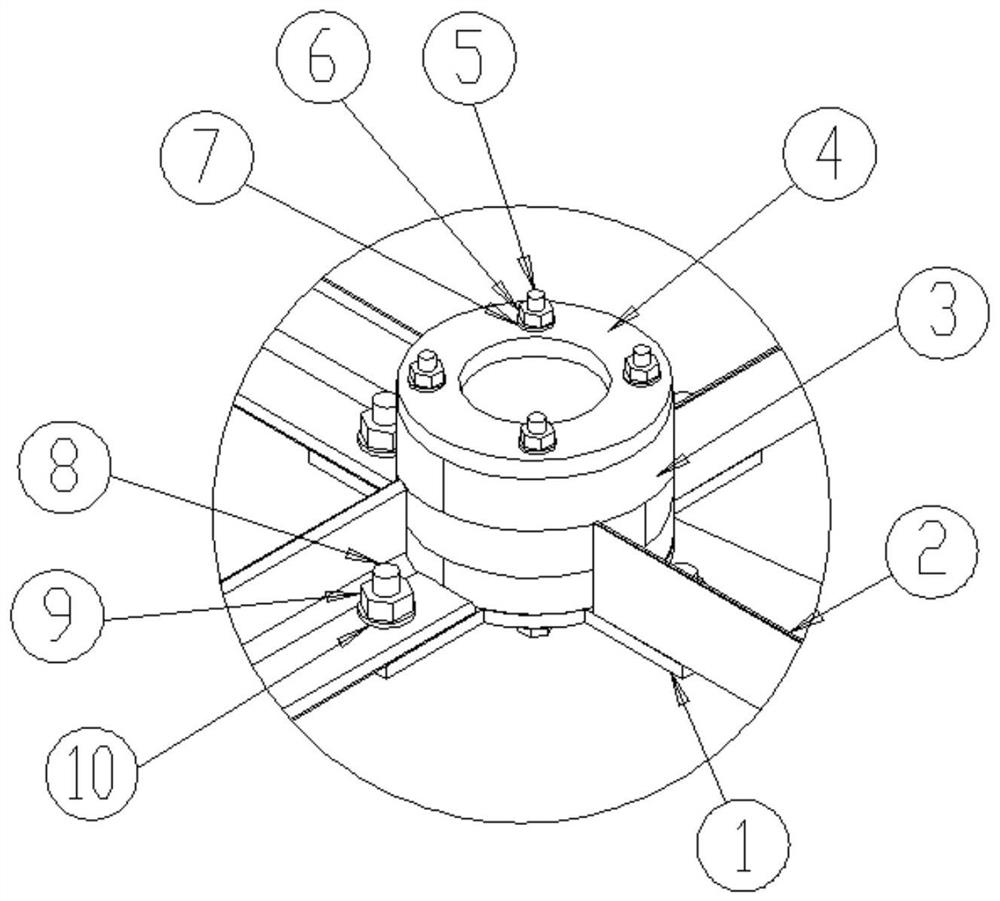

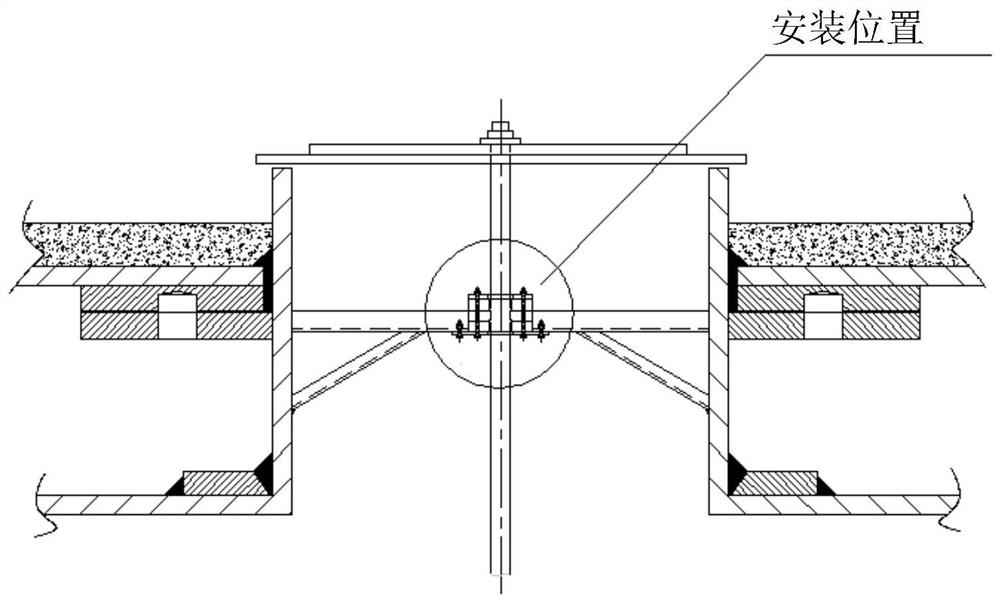

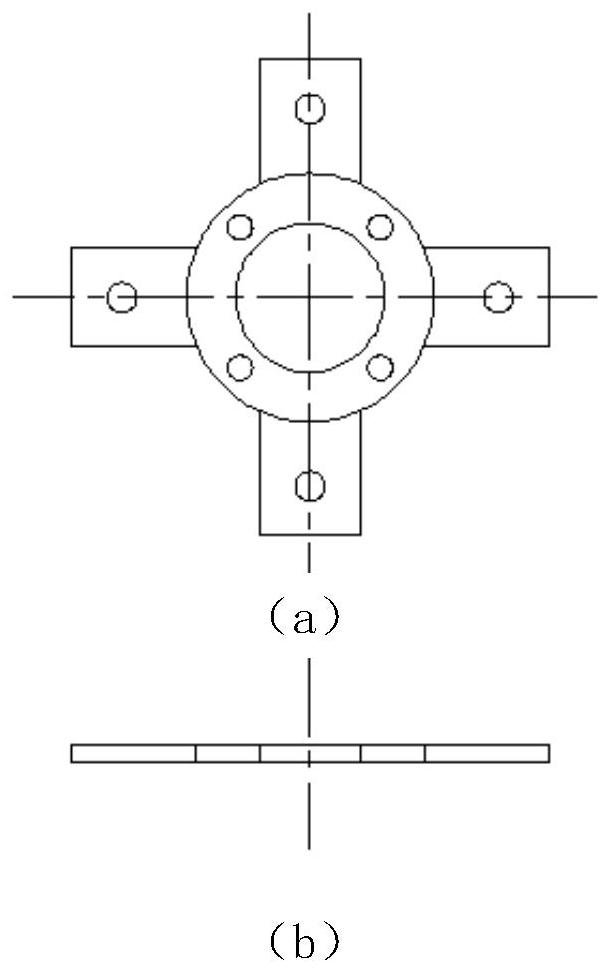

[0018] The poppet valve centering device can optionally be installed with one or more centering devices according to the stroke length of the poppet valve. The patent has the advantages of simple structure, easy processing and stable structure. The poppet valve centering device is made of carbon steel, including the centering piece base 1, the base bracket 2, the centering piece 3 and the centering piece pressing plate 4.

[0019] The centering member 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com