Steel cylinder valve emergency shut-off device

A valve and emergency technology, applied in the installation device of container structure, ship construction details, gas treatment/storage purpose, etc., can solve the problems of explosive gas and poisoning, prevent explosion and gas poisoning, improve safety performance, and ensure production safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

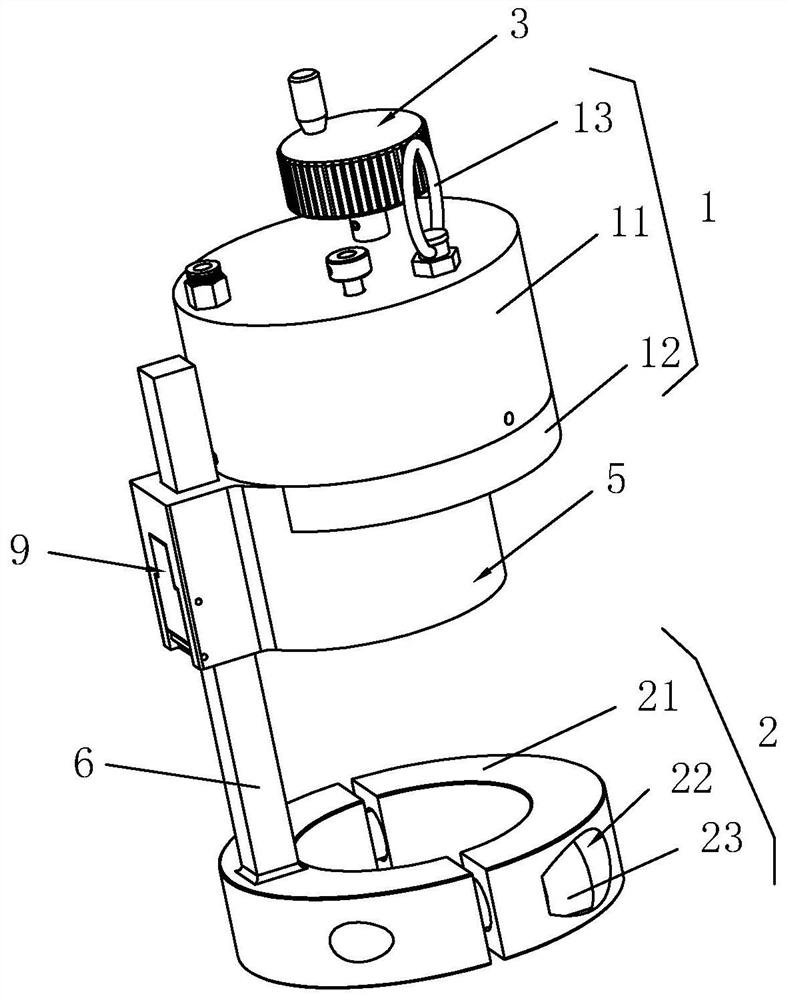

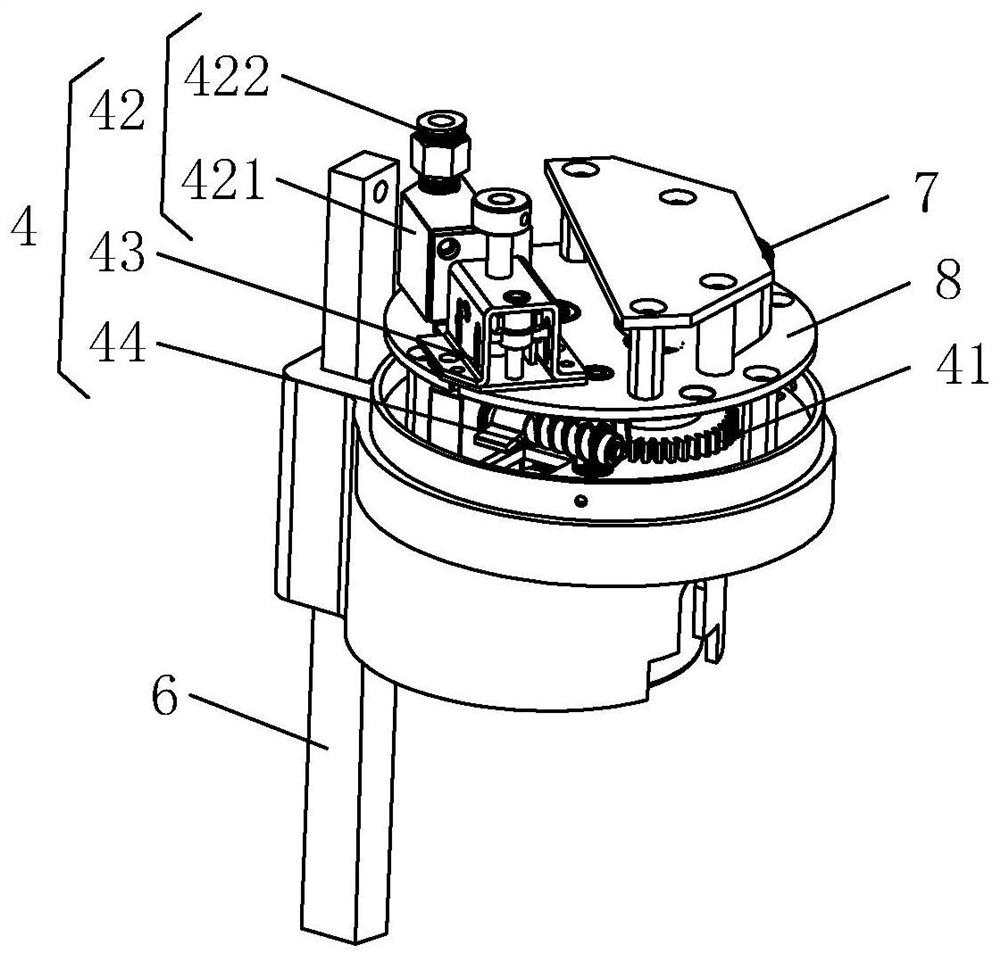

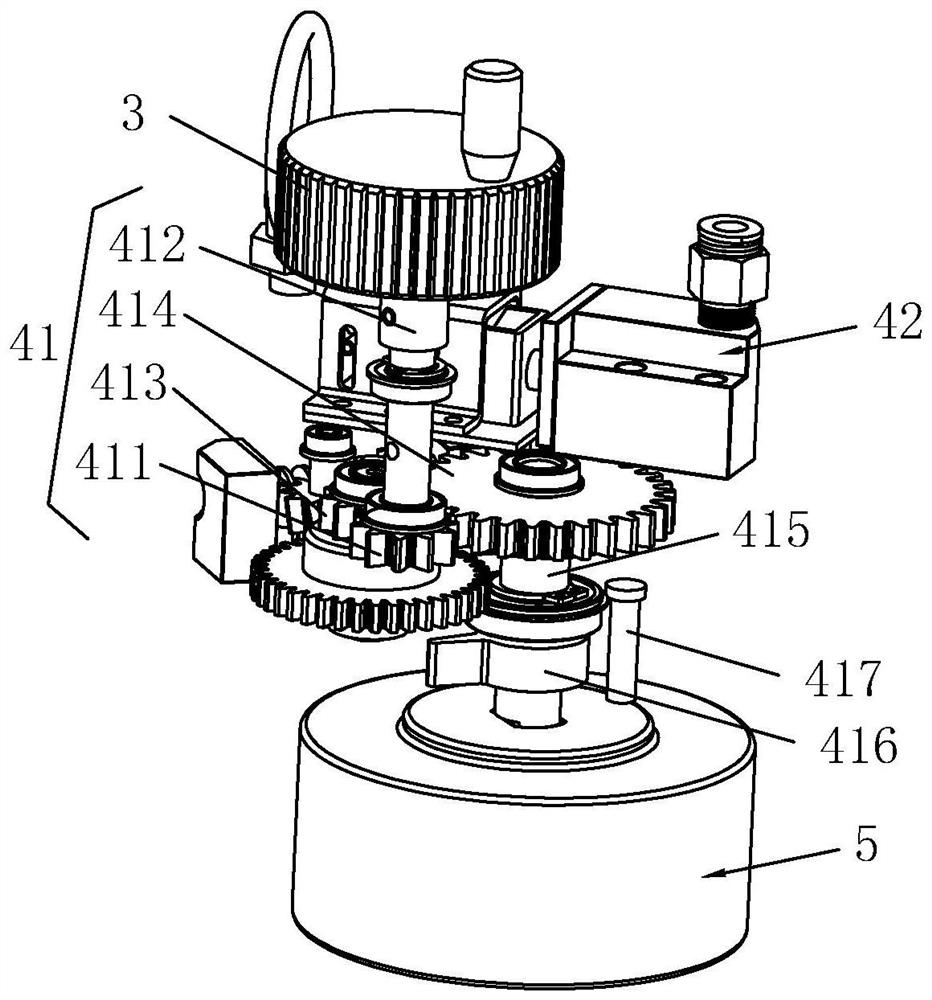

[0061] Such as Figure 1~2 As shown, the cylinder valve emergency shut-off device is used to realize emergency shut-off of the valve on the high-pressure container, including the shut-off device body 1, the valve fixing component 2, the operating component 3, the transmission component 4 and the valve shut-off component 5. The device body 1 is connected to the valve fixing assembly 2 through the bracket 6. The shut-off device body 1 is detachably mounted on the bracket 6. The shut-off device body 1 includes an upper shell 11 and a lower shell 12, and the lower shell 12 is passed through an adjustment member. 9 is detachably connected to the bracket 6, and the upper shell 11 is detachably connected to the lower shell 12. In this way, the joint action of the upper casing 11 and the lower casing 12 is used to protect the transmission assembly 4. Through the connection of the adjustment member 9, it is convenient to disassemble, repair or replace it, and it is convenient to use. ...

Embodiment 2

[0080] The difference between this embodiment and Implementation 1 is that: Figure 10 As shown, the cross section of the inner side wall of the shut-off chuck 51 is a structure composed of five equiangular arc surfaces, and the cross-section of the inner side wall of the shut-off chuck 51 has a petal-shaped structure as a whole. In this way, the shut-off chuck 51 can be adapted to the installation of different valves, which expands the application range of the shut-off device and has strong versatility.

[0081]The specific implementation principle of the present invention is: in the initial state, the air source is the continuous air supply of the cylinder 421, pull the pull rod 433 upwards, and under the action of the rotating member 436, drive the limiting rod 434 to move towards the direction of the worm 443 until the limiting rod 434 Insert into the inside of the limiting hole 446 to limit the work of the worm 443 and the worm wheel 442. At the same time, the cylinder 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com