Oil return control method and air conditioner

An oil return control and air conditioner technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problem of poor refrigeration and heating effect of air conditioning system, poor oil recovery effect, and inability to normally complete high-frequency oil return process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

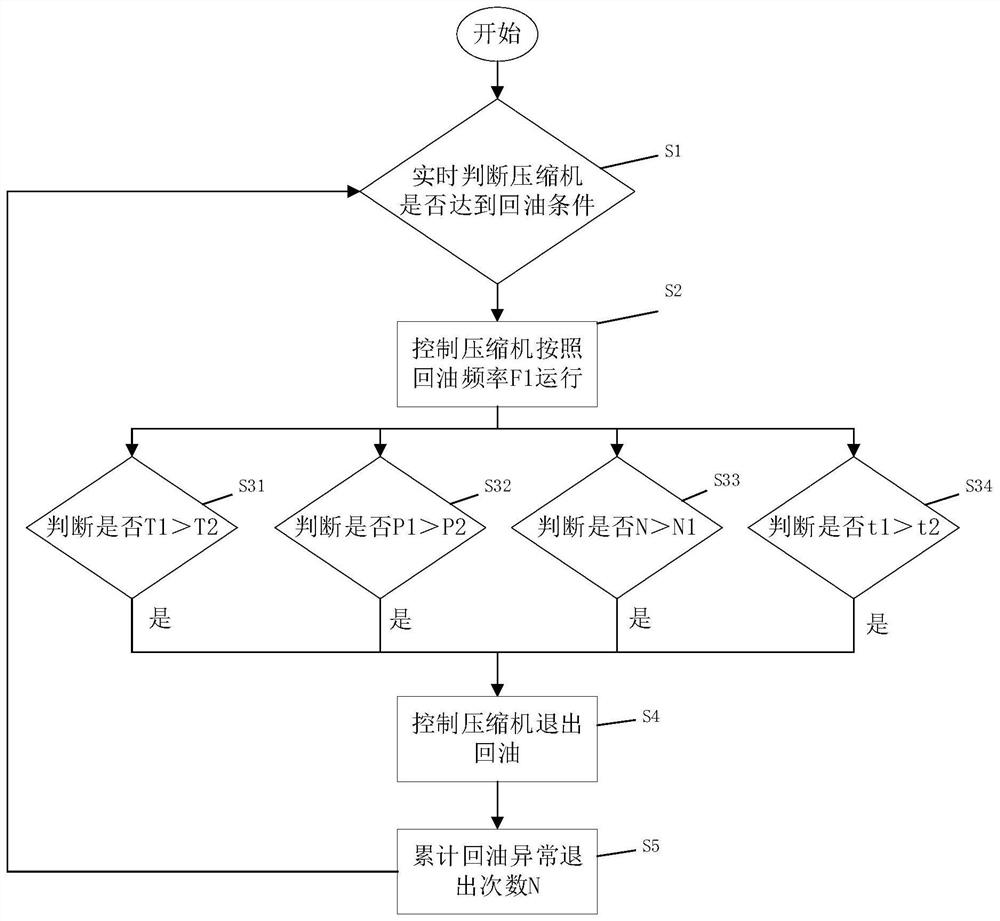

[0048] When the load of the air-conditioning system is high, the commonly used oil return control method cannot normally complete the high-frequency oil return process, which may lead to poor oil recovery effect, resulting in poor cooling and heating effects of the air-conditioning system.

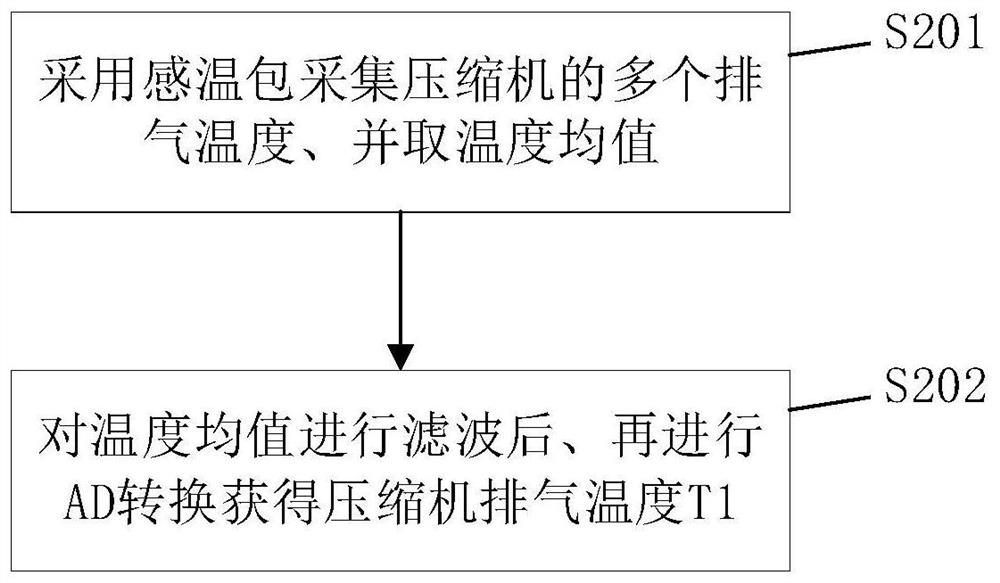

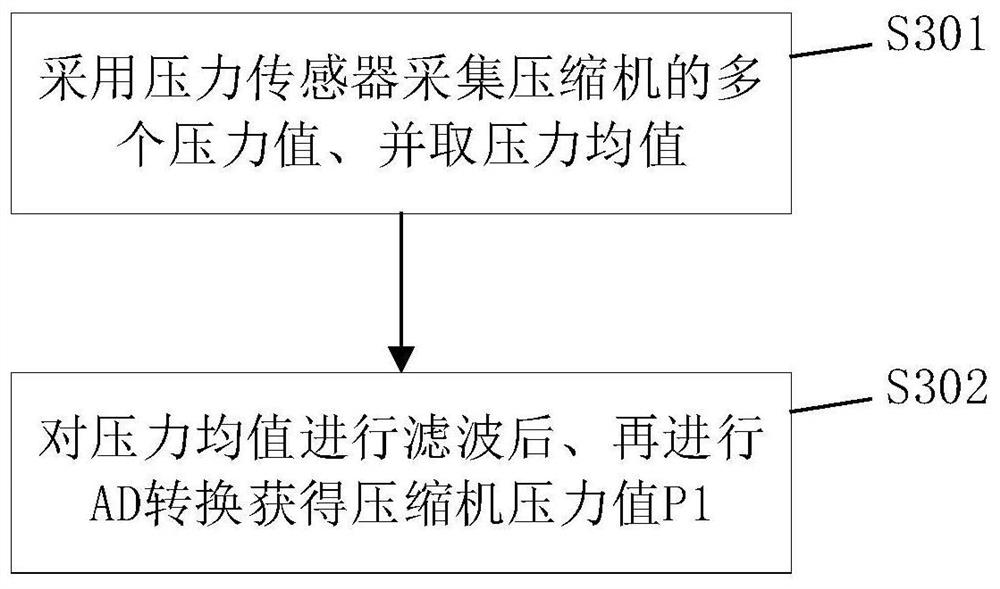

[0049] In view of the above disadvantages, the problem to be solved by the embodiment of the present invention is: when the air conditioner is in oil return operation, if the system pressure is too high or the exhaust temperature is too high, it can no longer operate according to the current oil return frequency, and it is necessary to exit the oil return and return to the low frequency However, considering that if it has been operated at a low frequency, the oil cannot be recovered, and the cooling and heating effects will be deteriorated. Therefore, the embodiment of the present invention records the number of abnormal oil return exits, and corresponds to different oil return control freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com