Device and method for detecting performance of linear guide rail pair clamp

A technology of linear guide pair and detection device, which is applied in the field of CNC machine tools, can solve the problems that the problems have not been well solved, there is no clamp performance detection, and the test device and test method have not been standardized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

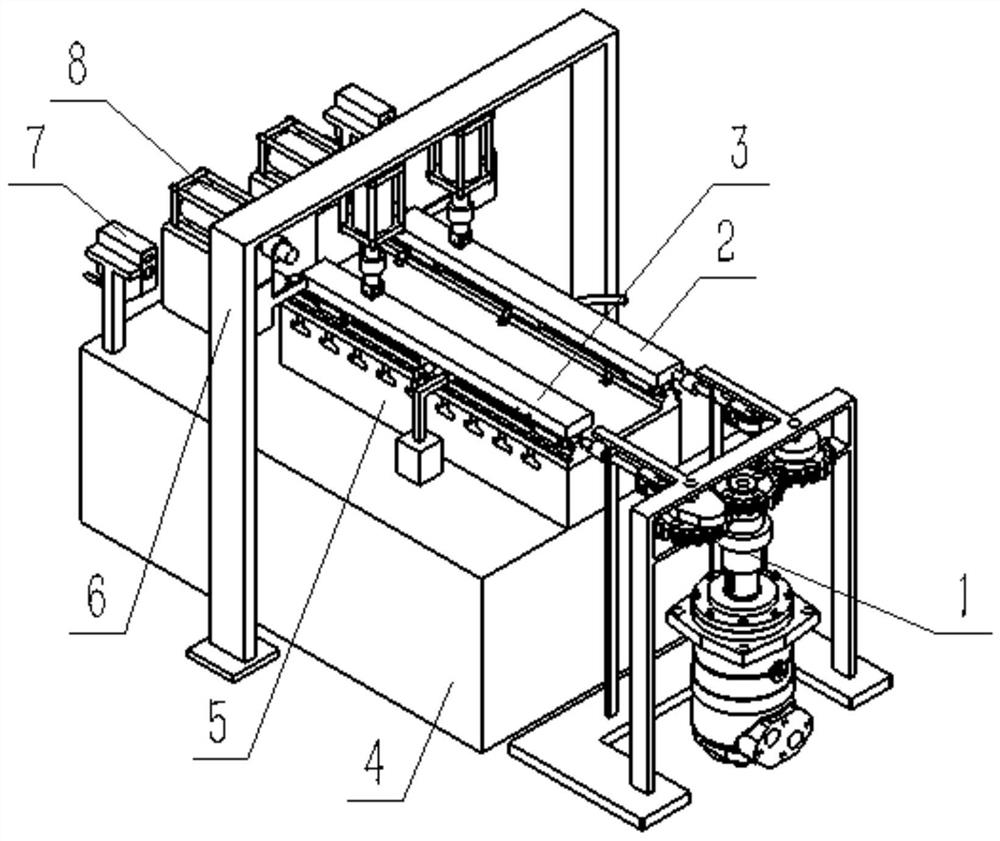

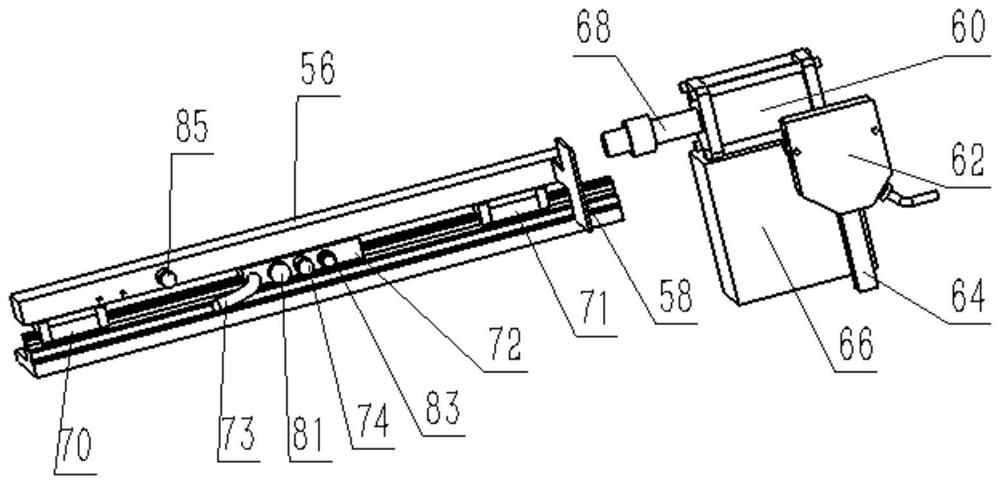

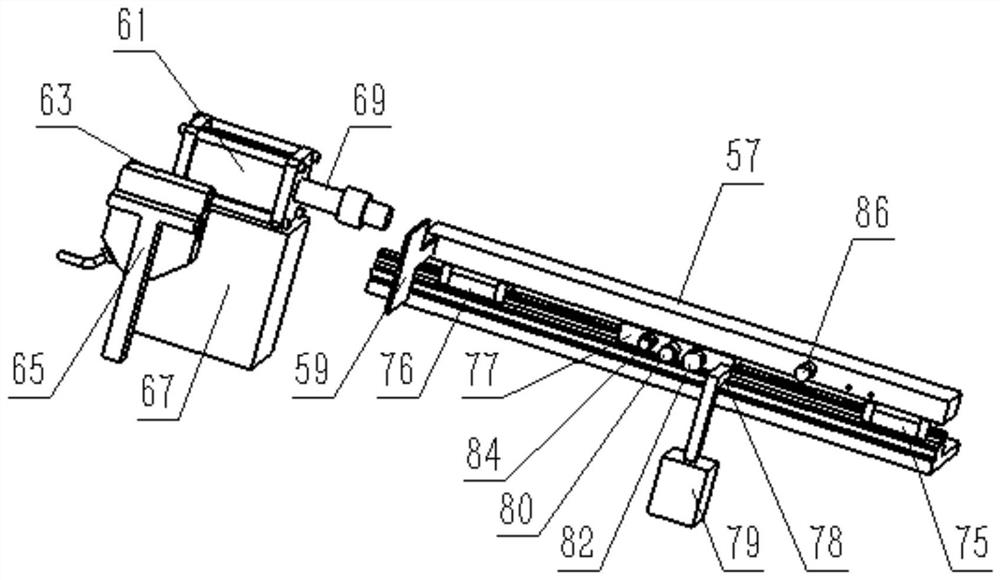

[0135] as attached figure 1 As shown, it is a schematic structural diagram of a detection device for the performance of a linear guide rail auxiliary clamp provided by an embodiment of the present invention, including a workbench mechanism for installing a hydraulic clamp 72 and / or a manual clamp 77, said The detection device also includes:

[0136] An axial loading mechanism 1 provided with an axial loading detection assembly is used to apply axial dynamic and / or static loads to the workbench mechanism; the axial loading detection assembly is used to detect the applied axial dynamic and / or static loads. / or static loads;

[0137] A longitudinal loading mechanism 6 provided with a longitudinal loading detection assembly is used to apply a longitudinal dynamic and / or static load to the workbench mechanism; the longitudinal loading detection assembly is used to detect the applied longitudinal dynamic and / or static load;

[0138] The performance detection mechanism is used to ...

Embodiment 2

[0254] An embodiment of the present invention provides a method for detecting the performance of a linear guide rail sub-clamp. The detection method includes the following steps:

[0255] Install the hydraulic clamp 72 and / or the manual clamp 77 on the workbench mechanism;

[0256] Applying dynamic and / or static loads to the workbench mechanism through the axial loading mechanism 1 and / or the longitudinal loading mechanism 6;

[0257] The hydraulic clamp 72 and / or the manual clamp 77 are detected by the performance detection mechanism.

[0258] Specifically, the linear guide rail vice clamp performance testing is divided into: clamp response time detection, clamp maximum holding force detection, clamp braking distance detection, clamp acceleration detection when braking, clamp wear detection and clamp temperature detection.

Embodiment 3

[0260] The embodiment of the present invention provides a detection method of the response time of the clamp according to embodiment 2, and the detection method includes the following steps:

[0261] S101, install a hydraulic clamp 72 or a manual clamp 77 according to the type of clamp to be detected;

[0262] S102, according to the simulated loading condition of the clamp, install the axial loading mechanism 1 and the longitudinal loading mechanism 6, if it is no-load condition, do not install the loading part;

[0263] S103, install the clamper reaction time detection assembly, install the first acceleration vibration sensor 74 on the side of the hydraulic clamp 72, install the second acceleration vibration sensor 80 on the side of the manual clamping fixture 77, and install the first acceleration vibration sensor 74 and The data transmission line of the second acceleration vibration sensor 80 is connected with the computer equipment, and debugs the corresponding data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com