Simulation Christmas tree branch binding machine

A technology of tree branches and tying branches, which is applied in the field of artificial Christmas tree equipment, can solve the problems of high labor intensity, high cost, and easy fatigue of operators, and achieve the effect of cost reduction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

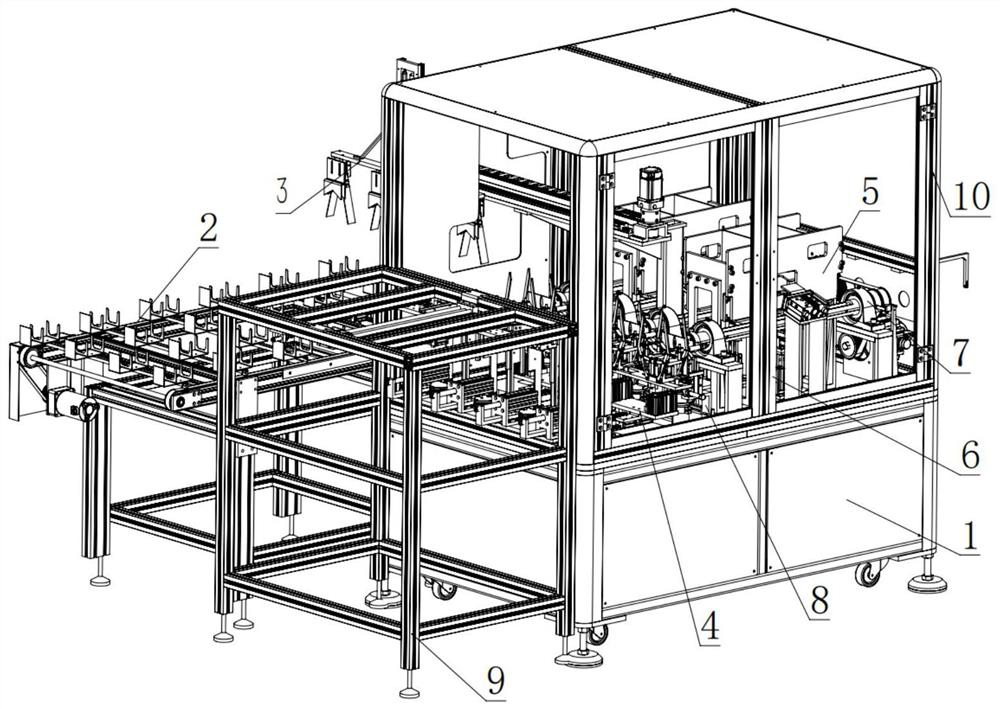

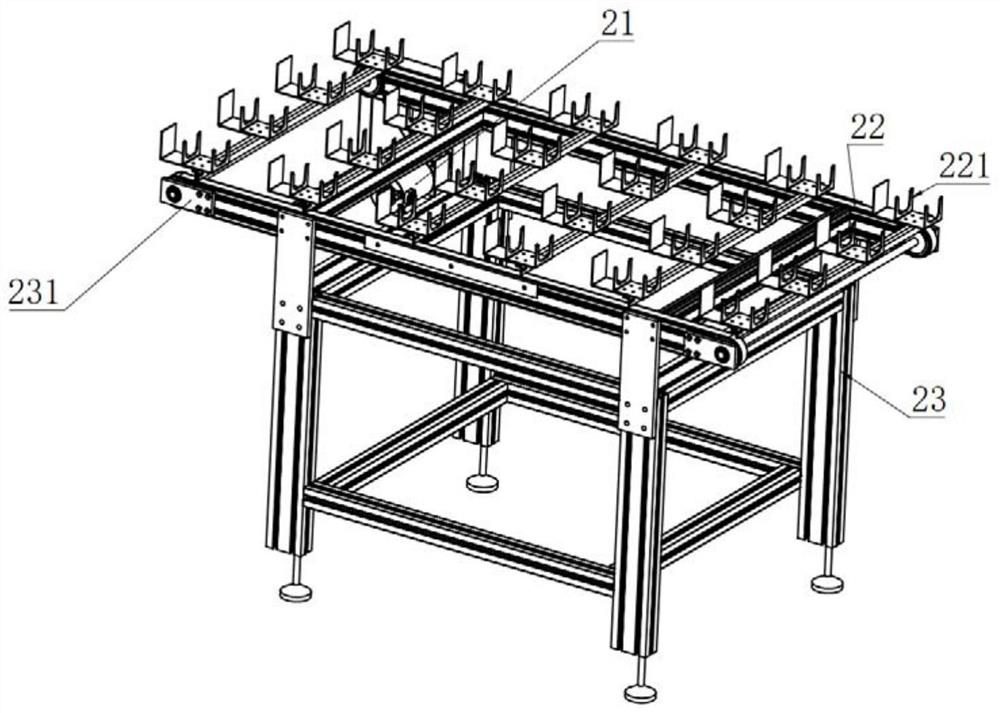

[0024] In this embodiment, a Christmas tree branch tying machine includes a circular conveying line mechanism 2, manually placing simulated Christmas tree branches on the jaws of the circulating conveying mechanism one by one, and circularly conveying the simulated Christmas tree branches. Four sets of equally spaced grippers 321 are used to grab branches in the branch feeding mechanism 3, and four sets of equally spaced grippers 321 are driven to move left and right through the horizontal servo linear motion module of the branch feeding mechanism 3, and a cylinder 33 is installed vertically to control the four groups The equidistant clamping jaws 321 move up and down to uniformly grasp the branches to the front claw parts 42 of the branch clamping mechanism 4 .

[0025] In this embodiment, two iron rod stock bins 51 are arranged on the bar material distribution mechanism 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com