Engineering garbage treatment equipment for building

A technology of waste treatment equipment and engineering, applied in the engineering field of construction, can solve the problems of inconvenient waste treatment, polluted land, and construction waste cannot be effectively treated, and achieves the effect of increasing stability and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

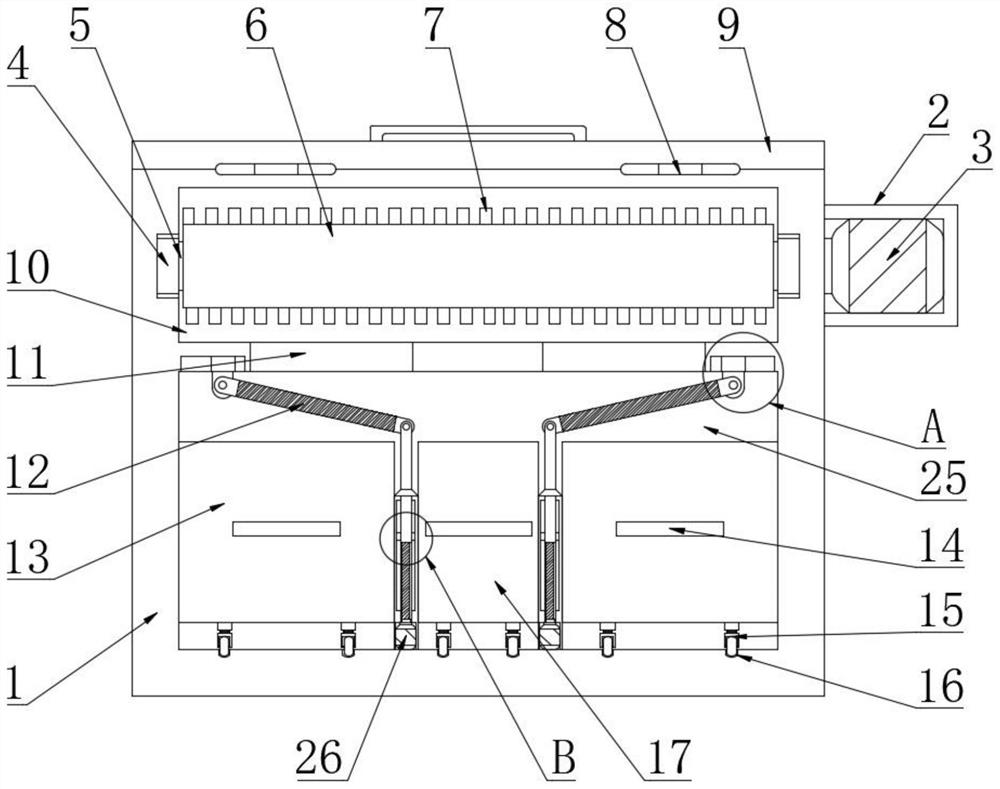

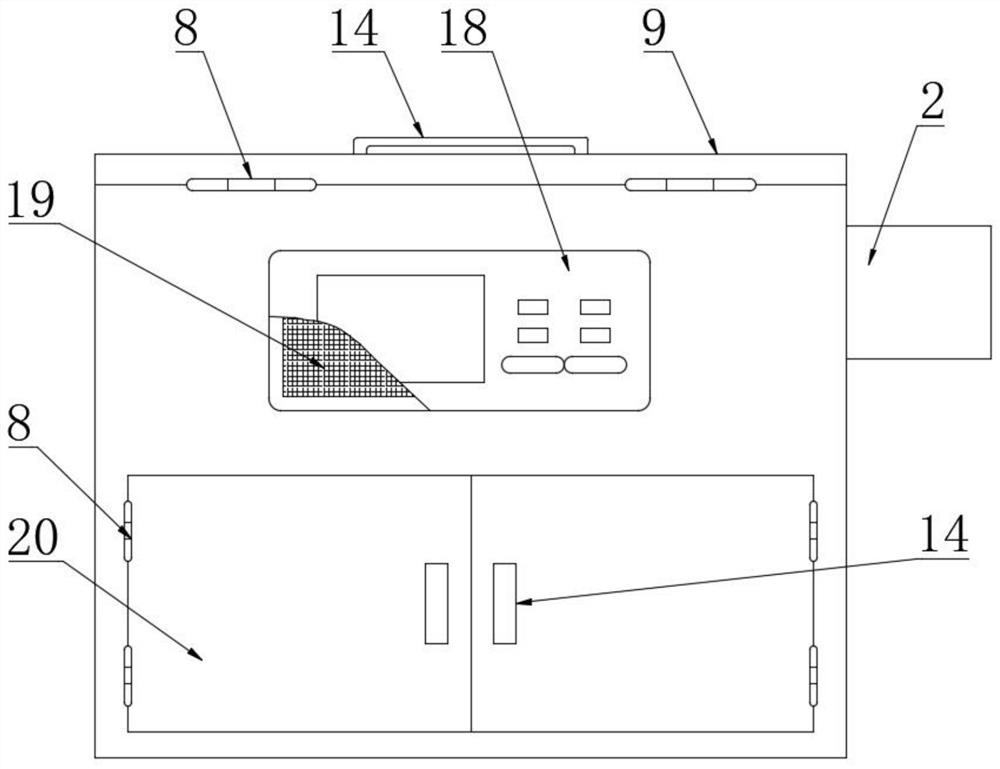

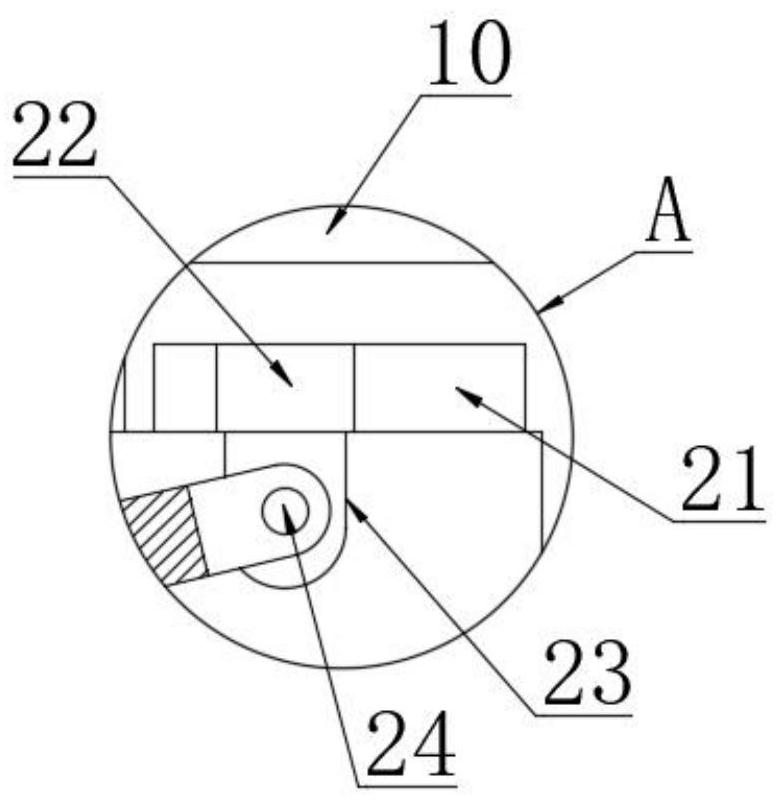

[0024] see Figure 1-6 , the present invention provides the following technical solutions: a building engineering waste treatment equipment, including a box body 1, a crushing chamber 10 and a collection chamber 25 are opened inside the box body 1, and four bearings 4 are inlaid on the inner wall of the crushing chamber 10 , the bearing 4 is pierced with a rotating shaft 5, the surface of the rotating shaft 5 is fixedly connected with a drum 6, the surface of the drum 6 and the inner wall of the crushing chamber 10 are fixedly connected with crushing teeth 7, the right side of the box 1 The outer surface is fixedly connected with a fixed frame 2, and the fixed frame 2 is fixedly connected with a first motor 3. By setting the first motor 3, the drum 6 and the crushing teeth 7 can be driven to rotate through the rotating shaft 5. At the same time, the two drums 6 and The rubbish is crushed under the interaction of the crushing teeth 7, which is convenient for users to crush rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com