Smashing type garbage classification box for environment design and smashing classification method thereof

A garbage sorting and crushing technology, which is applied in the direction of garbage cans, garbage collection, chemical instruments and methods, etc., can solve the problems of waste of resources, disorderly, multi-space, etc., and achieve the goal of reducing recycling time, saving complex processes, and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

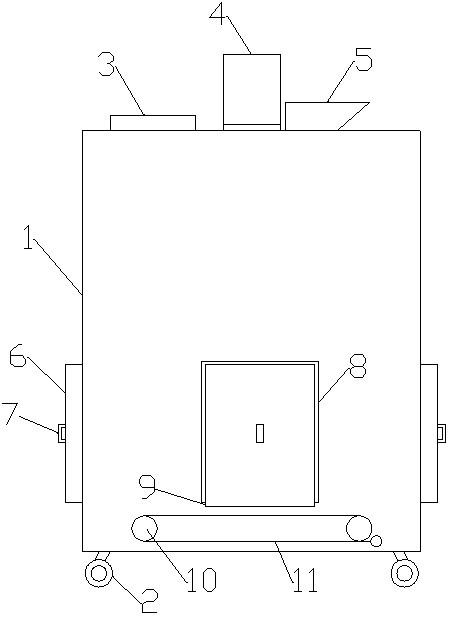

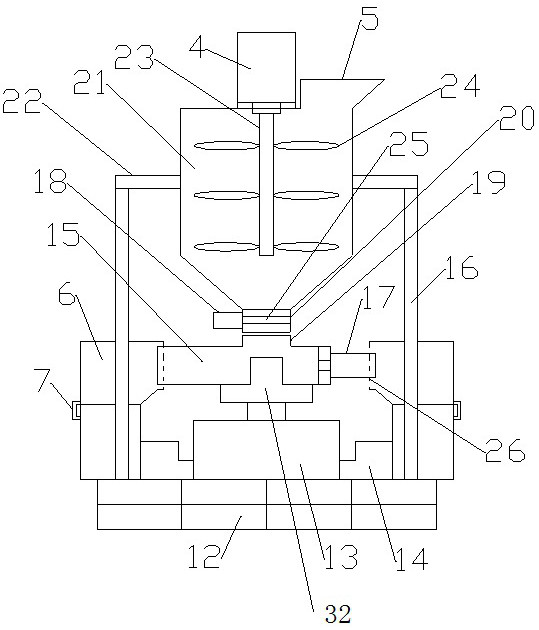

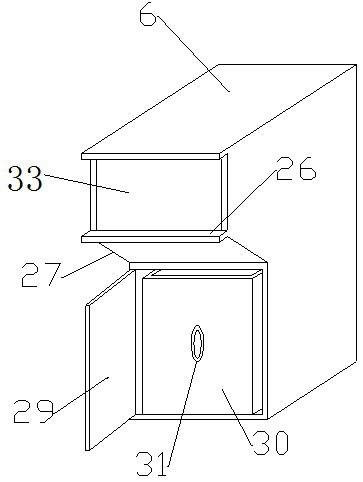

[0018] Such as figure 1 , 2 As shown in , 3 and 4, a pulverized garbage sorting box for environmental design includes a box body 1 with a feeding hopper 5 on the top, and a rotating motor is fixedly installed at the center of the top of the box body 1 on one side of the feeding hopper 5 4. A controller 3 is fixedly installed on the top of the casing 1 on one side of the rotating motor 4, and a pulverizing storage cylinder 21 communicating with the feeding hopper 5 is installed in the casing 1 below the rotating motor 4. In the pulverizing storage cylinder 21 Inside longitudinally is provided with the rotating shaft 23 that the top is connected with the output end of rotating motor 4, and crushing blade 24 is installed on the rotating shaft 23, and the bottom of crushing material storage cylinder 21 is connected with discharge pipe 20, and the bottom of discharge pipe 20 A feed inlet 19 is provided, and the bottom of the feed inlet 19 communicates with the spiral discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com