Organic solid waste pyrolysis and gasification system and method

A technology of pyrolysis gasification and organic solid waste, which is applied in the direction of gasification process, details of gasification device, and production of combustible gas, etc. It can solve problems such as high tar content, high dust content of pyrolysis gas, and high thermal ignition loss rate of slag , to achieve the effect of reducing investment cost, improving combustion efficiency and wide application range of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

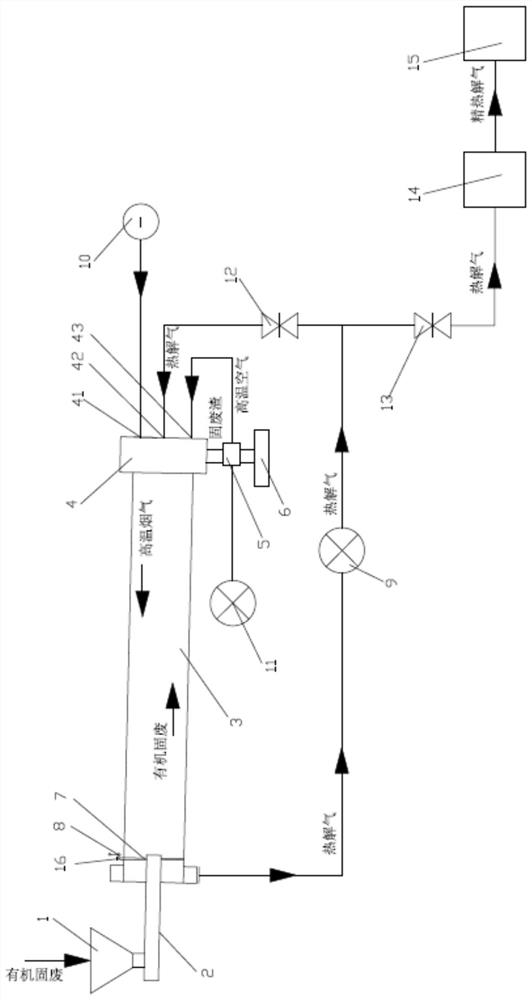

[0036] like figure 1 As shown, an organic solid waste pyrolysis gasification system provided in this embodiment includes a feed hopper 1, a shaftless screw feeder 2, a rotary gasification kiln 3, a combustion chamber 4, a high-temperature air preheater 5, a cooling Slag machine 6, high temperature dust removal net 7, electric vibrating hammer 8, pyrolysis gas blower 9, ignition aid fuel pump 10, combustion support fan 11, combustion adjustment door 12, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap