Road concrete prepared from waterworks sludge powder and coral fine aggregate

A technology of waterworks and sludge powder, which is applied in the field of building materials, can solve the problems of land secondary pollution, etc., and achieve the effect of improving early strength, improving activity, and improving interface transition zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

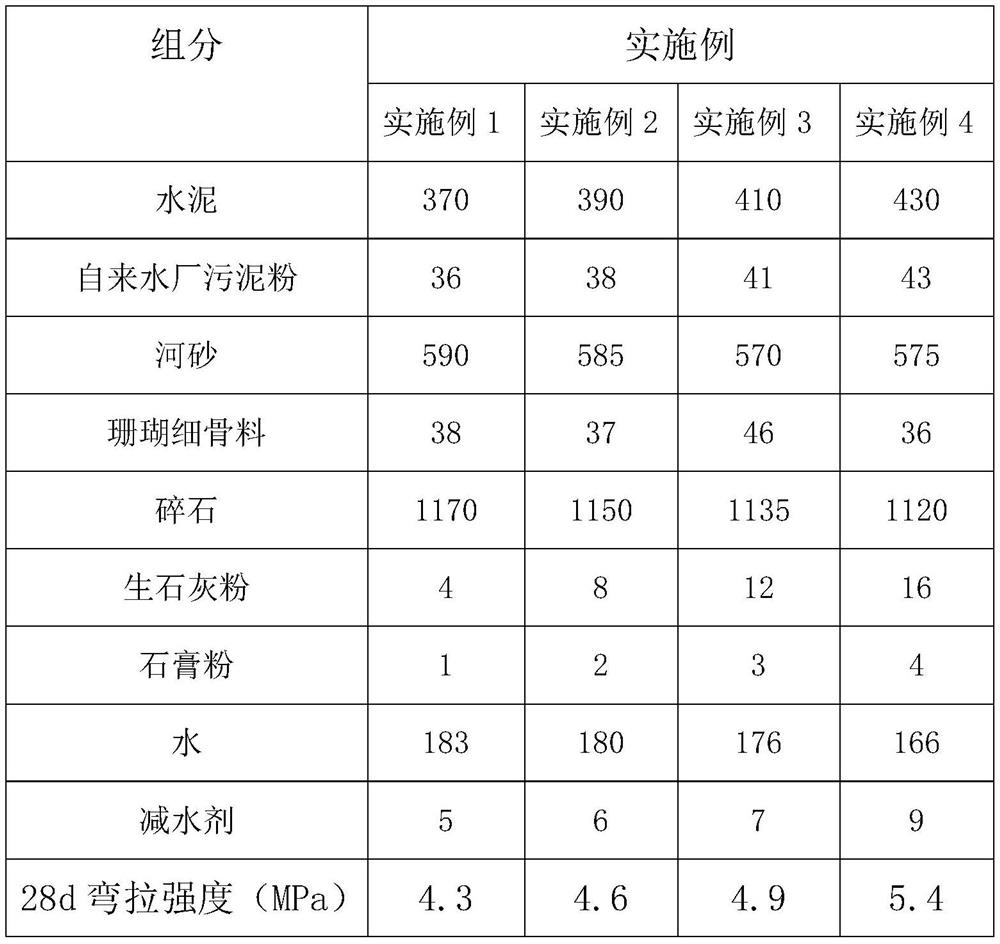

Embodiment 1

[0039] Concrete for highways prepared from waterworks sludge powder and coral fine aggregate, calculated by weight components, includes the following components,

[0040] 370 parts of cement with P O 52.5, 36 parts of sludge powder from waterworks, 590 parts of river sand, 38 parts of coral fine aggregate, 1170 parts of crushed stone, 4 parts of quicklime powder, 1 part of gypsum powder, 183 parts of water, water reduction 5 parts of agent, water-binder ratio 0.45.

[0041] The technical index of the road concrete prepared by using the sludge powder from the waterworks in this embodiment: the 28d bending tensile strength is 4.3MPa.

Embodiment 2

[0043] Concrete for highways prepared from waterworks sludge powder and coral fine aggregate, calculated by weight components, includes the following components,

[0044] 390 parts of cement with P O 52.5, 38 parts of sludge powder from waterworks, 585 parts of river sand, 37 parts of coral fine aggregate, 1150 parts of crushed stone, 8 parts of quicklime powder, 2 parts of gypsum powder, 180 parts of water, water reduction 6 parts of agent, water-binder ratio 0.42.

[0045] The technical index of the road concrete prepared by adopting the sludge powder from the waterworks in this embodiment: the 28d bending tensile strength is 4.6MPa.

Embodiment 3

[0047] Concrete for highways prepared from waterworks sludge powder and coral fine aggregate, calculated by weight components, includes the following components,

[0048] 410 parts of cement with P O 52.5, 41 parts of sludge powder from waterworks, 570 parts of river sand, 46 parts of coral fine aggregate, 1135 parts of crushed stone, 12 parts of quicklime powder, 3 parts of gypsum powder, 176 parts of water, water reduction 7 parts of agent, water-binder ratio 0.39.

[0049] The technical index of the road concrete prepared by adopting the sludge powder from the waterworks in this embodiment: the 28d bending tensile strength is 4.9MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com