Transition layer structure of rockfill concrete gravity dam and construction method thereof

A technology of rockfill concrete and transition layer, which is applied in the direction of gravity dams, dams, barrages, etc., can solve the problems of high flatness of the rockfill surface, insufficient refinement, hidden dangers of anti-sliding and stability of the dam layer, etc., to achieve convenient construction, The effect of improving the anti-skid stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

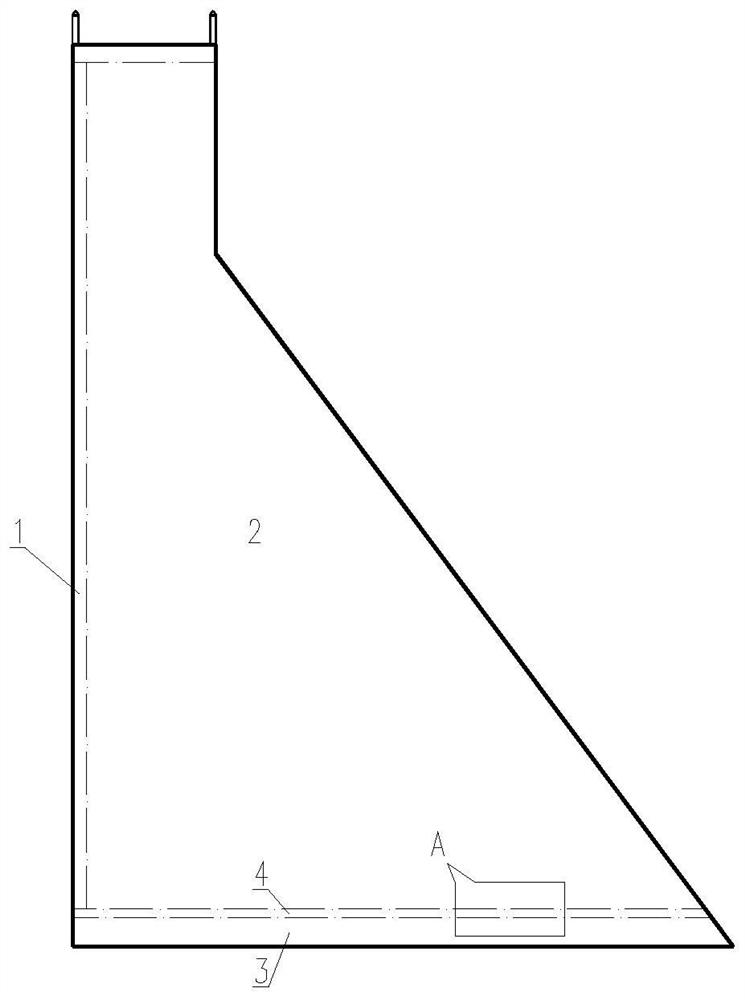

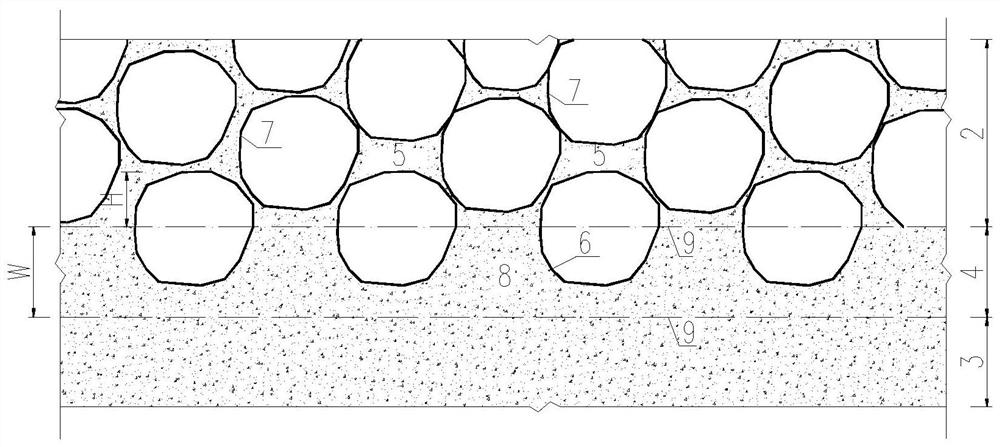

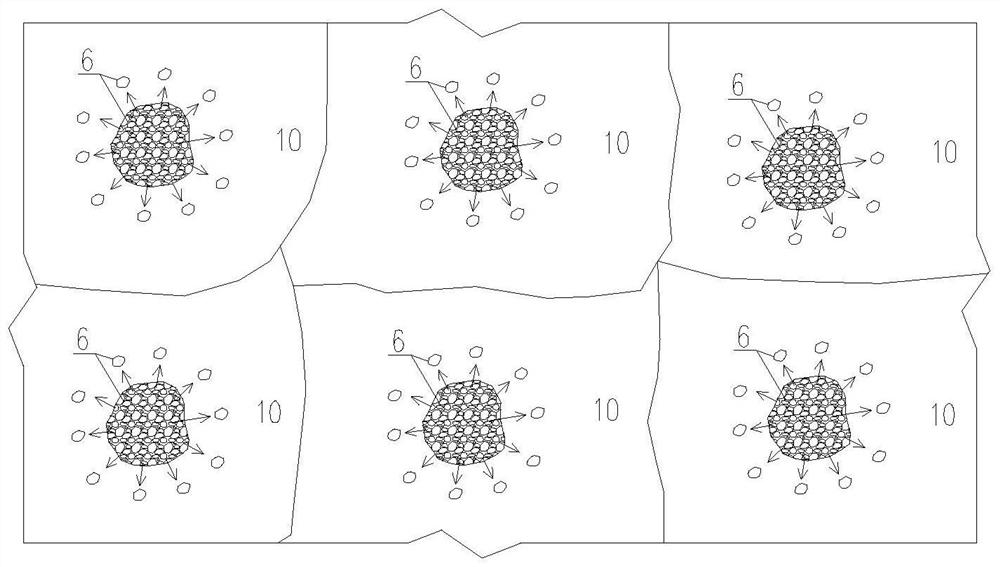

[0023] Such as Figure 1-3 Shown, the present invention is implemented like this: pouring normal concrete cushion 3 on the dam base surface of rockfill concrete gravity dam and after doing artificial chiseling or high-pressure water gun roughening treatment on its surface, treat that the normal concrete 3 of dam body cushion reaches The strength is required in the design. On the normal concrete 3 of the cushion of the dam body, the rockfill 16 is piled up in separate warehouses. It is required that the size of the pre-stacked stone warehouse surface 10 should not be too large, and should be less than 100m 2 After the pre-stacked stone storehouse surface 10 has completed the stacking of the rockfill-6, pour 30cm thick normal concrete 8 on the pre-stacked stone storehouse surface 10; Finally, mechanically supplemented by manual methods, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com