Coal mine underground complex stratum directional drilling pressure control drilling system

A complex formation, directional drilling technology, applied in directional drilling, drilling tools, drilling equipment, etc., can solve problems such as reducing the effect of flushing fluid, and achieve the effects of improving stability, increasing pressurization effect, and reducing the possibility of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

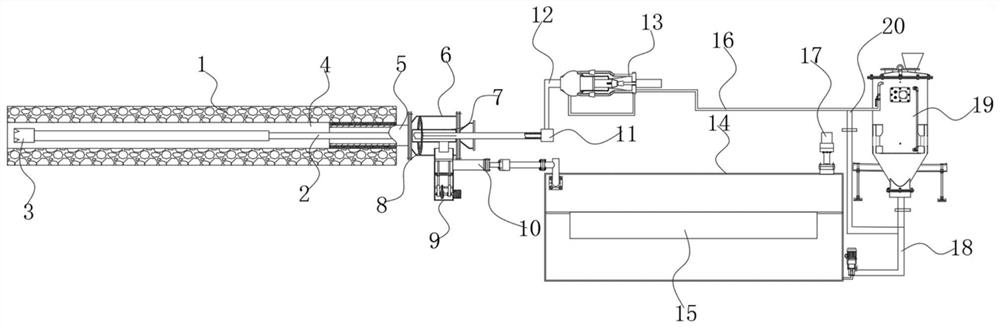

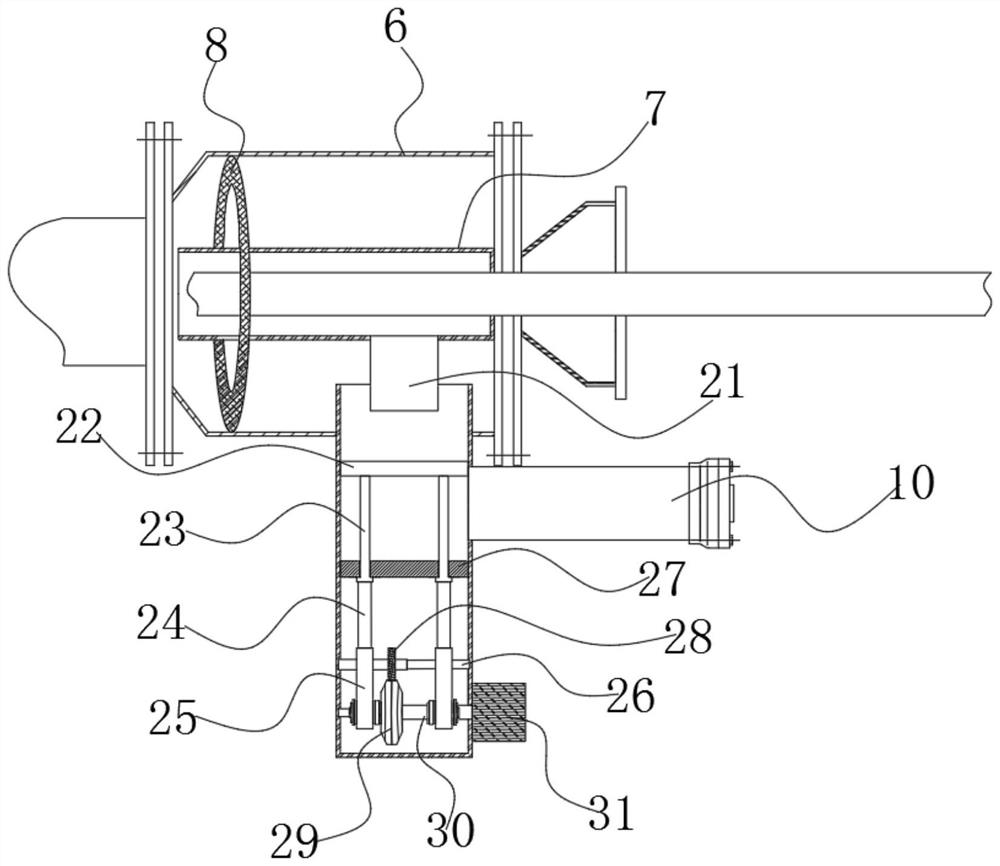

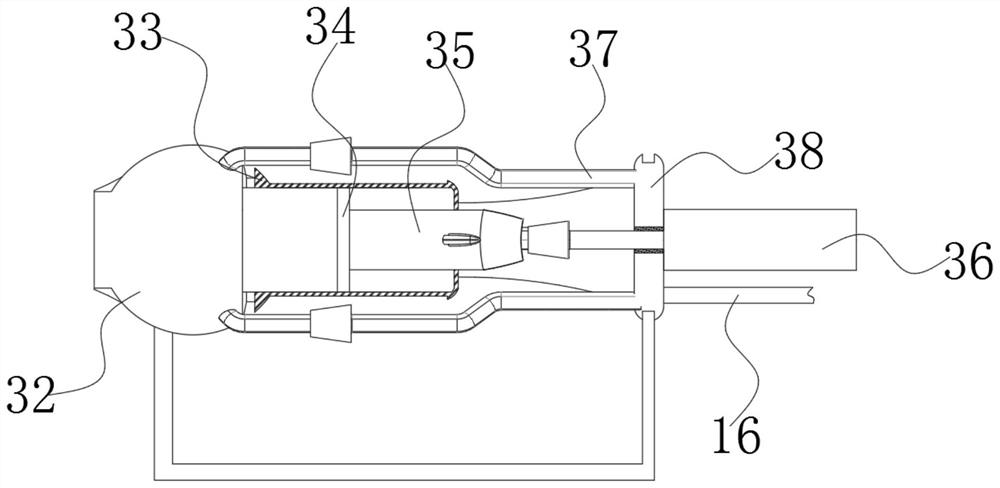

[0026] see Figure 1~3 , in an embodiment of the present invention, a directional drilling and pressure-controlled drilling system for complex underground coal mine formations, which includes a drill pipe 2, a sealing tube 5, a water release chamber 6, a hydraulic pressure control assembly and a hydraulic pressure control assembly 13, Wherein, the drill pipe 2 extends into the borehole 1 and forms an annulus 4 with the borehole 1, and a sealing pipe 5 is fixedly embedded at the entrance of the borehole 1, so that the mixed liquid in the annulus 4 flows through Seal tube 5 to the outside,

[0027] Wherein, the sealing pipe 5 is connected with the water release chamber 6 by a flange, and the bottom of the water discharge chamber 6 is connected with the liquid outlet pressure control assembly, and the liquid outlet control pressure assembly can adjust the seal of the liquid outlet. Blockage area, so as to control the liquid outlet pressure of the mixed liquid in the annular spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com