Method and device for reducing wear of engine valve guide

An engine valve and valve guide technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as valve guide wear, and achieve the effects of avoiding wear, reducing wear, and reducing exhaust temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

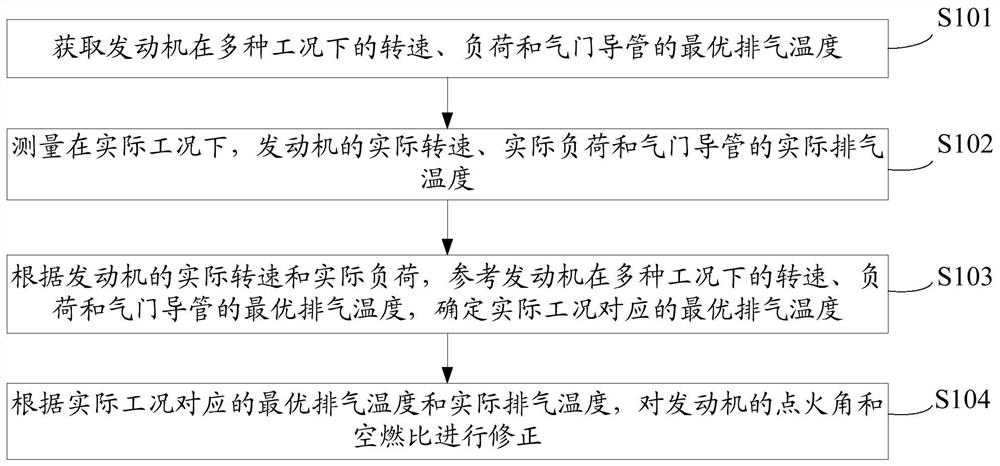

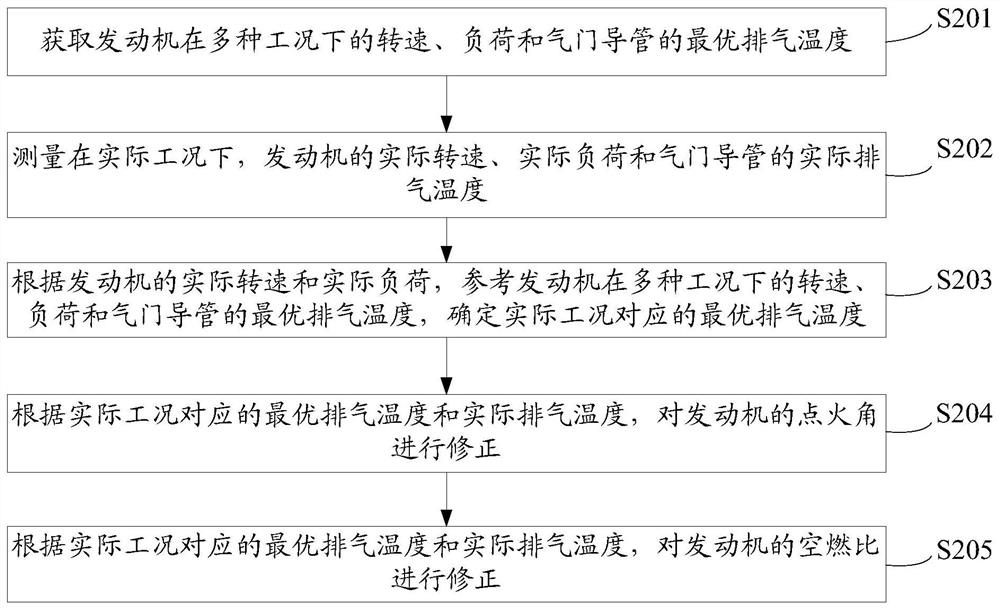

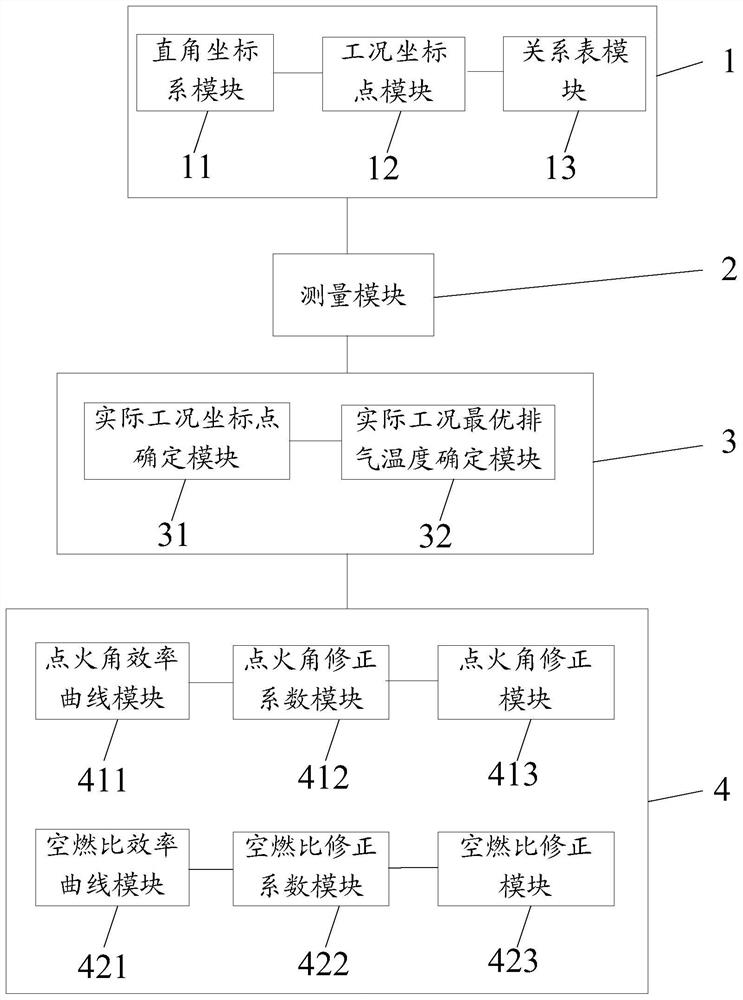

[0056] figure 1 is a flow chart of a method for reducing engine valve guide wear provided by an embodiment of the present disclosure, such as figure 1 As shown, the method includes:

[0057] S101. Obtain the engine speed, load and optimal exhaust temperature of the valve guide under various working conditions.

[0058] S102. Measure the actual engine speed, actual load, and actual exhaust temperature of the valve guide under actual working conditions.

[0059] S103. According to the actual speed and actual load of the engine, referring to the speed and load of the engine under various working conditions and the optimal exhaust temperature of the valve guide, determine the optimal exhaust temperature corresponding to the actual wor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap