Automatic sampling equipment and method for surface soil in dry land

A technology of automatic sampling and sampling equipment, applied in the direction of sampling, sampling devices, instruments, etc., can solve the problems of low degree of automation of soil sampling, inaccurate sampling, and high labor intensity, so as to reduce labor intensity, improve sampling efficiency, and improve sampling efficiency. The effect of the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

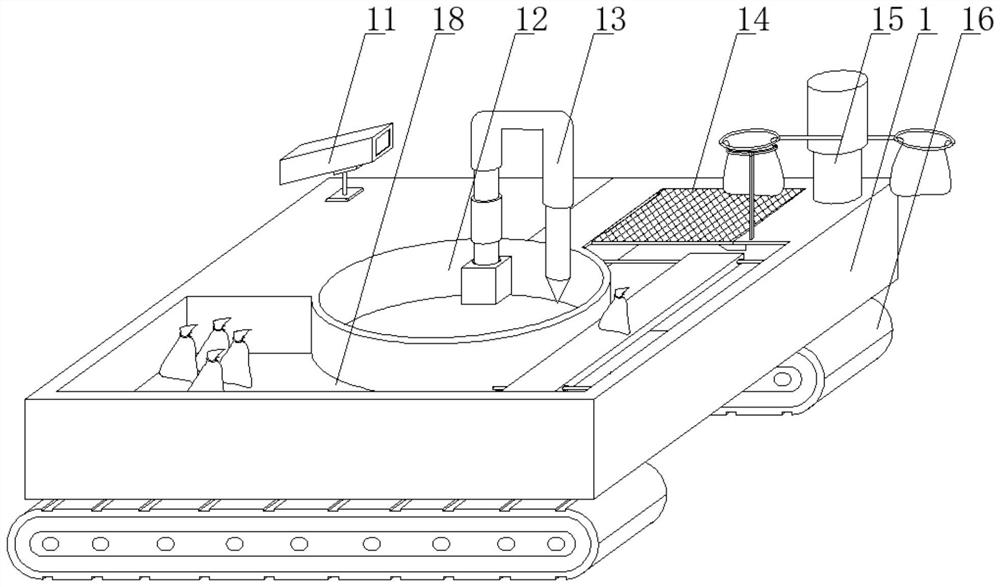

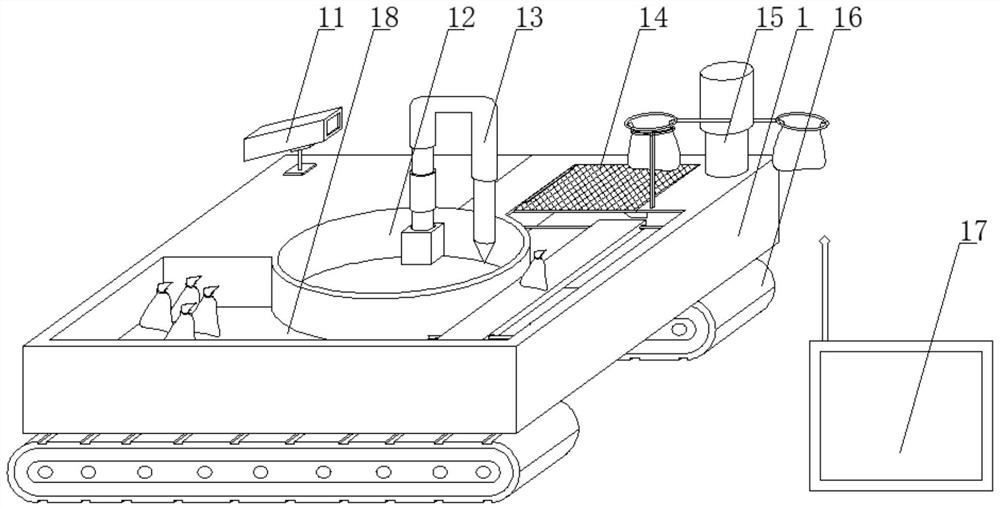

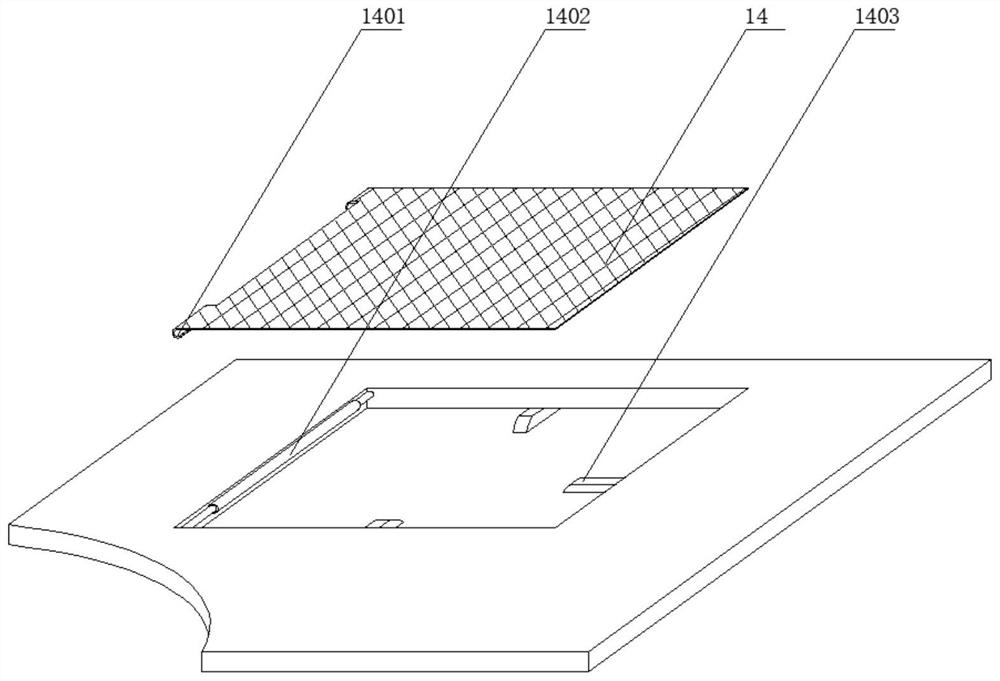

[0053] Such as figure 1 and figure 2 As shown, Embodiment 1 of the present invention discloses an automatic sampling device for dryland surface soil, including a workbench 1, the shell of the workbench 1 forms a cavity inside, and a center position of the cavity is provided with a sampler 13 The installation hole 12 of the workbench 1 is formed with an opening communicating with the conveying mechanism 19, and the shielding member 14, conveying mechanism 19 and sample storage area 18 installed on the opening will surround the sampler 13 clockwise or counterclockwise (not shown) out) are arranged on the workbench 1 in turn, the sealing device 15 is arranged at the position corresponding to the shielding member 14, the camera 11 is arranged in the front of the movement direction of the workbench 1, and the bottom of the workbench 1 is provided with a traveling mechanism, and the traveling mechanism Preferred crawler belts 16 can improve the balance of the workbench 1 moving in...

Embodiment 2

[0079] The present invention also provides a method for automatic sampling of topsoil in dry land, such as Figure 7 As shown, for multi-point soil sampling of the same plot, the method includes:

[0080] S1: controlling the sampling device to automatically navigate and move to the sampling point according to the positioning information and the moving path of the sampling point;

[0081] S2: Control the sampler to sample soil at the sampling point, and put the collected soil sample into a sample bag;

[0082] Specifically, when the workbench moves to a sampling point according to the sampling path, the controller controls the sampler to sample the soil at the sampling point, and then the workbench continues to move to the next sampling point along the sampling path, and after reaching the next sampling point , take soil sampling here, and put it into the same sample bag; repeat the sampling action until the sampling of all points is completed.

[0083] S3: After the sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com