Welding seam shooting tool and process thereof

A tooling and film technology, applied in measurement devices, transportation and packaging, transportation of passenger cars, etc., can solve the problems of 100% flaw detection, inability to guarantee filming, and inflexible and convenient operation methods, so as to reduce detection costs and operation difficulties. , The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

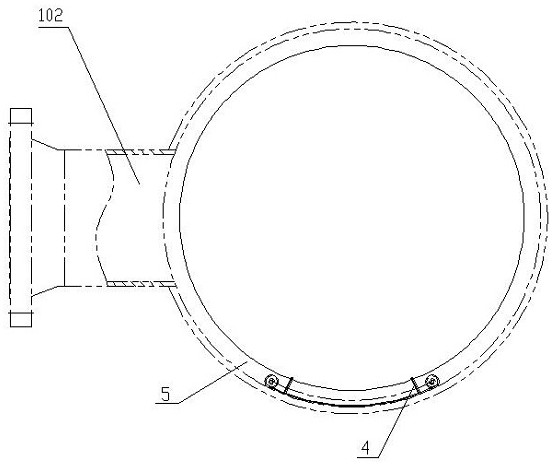

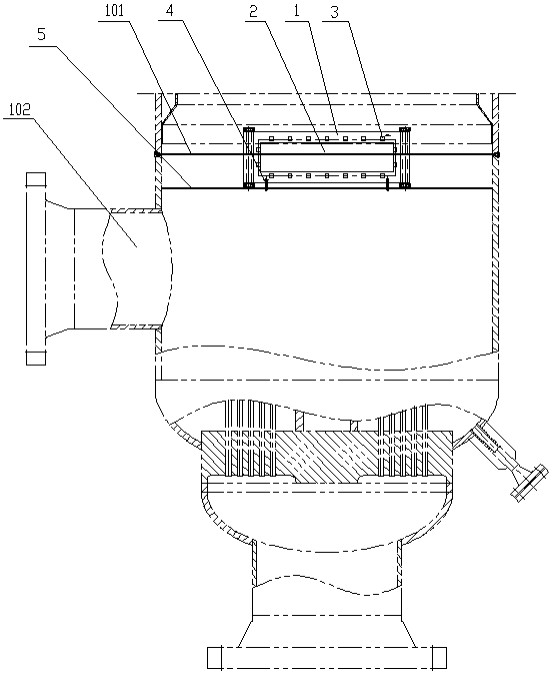

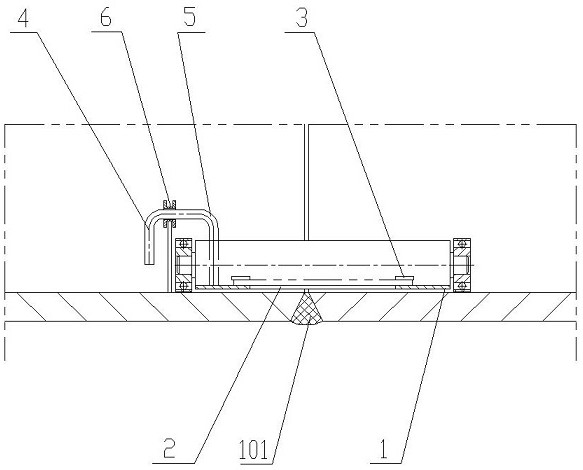

[0025] see Figure 1~3 , a kind of welding seam photographing tooling involved in the present invention includes a walking trolley 1 that walks above the weld seam of the cylinder through a guiding mechanism. The through hole, the bottom sheet 2 is covered on the through hole;

[0026] Further, the guide mechanism includes an annular guide rail 5 installed along the inner wall of the cylinder, and a guide hook 4 installed on the trolley 1, and the guide hook 4 is hooked on the annular guide rail 5; preferably, the guide hook 4. There are two front and rear ones; preferably, the guide hook 4 is set with a guide wheel 6, and the guide wheel 6 walks on the annular guide rail 5;

[0027] Further, the two ends of the walking trolley 1 are provided with installation shafts, and the two ends of the installation shaft are provided with rolling parts (such as bearings); or the four corners of the walking trolley 1 are installed with rollers rolling along the radial direction of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com