A board-to-board connector joint detection and packaging equipment

A board-to-board connector and packaging equipment technology, applied in transportation and packaging, packaging, packaging machines, etc., can solve the problems of low packaging efficiency and incomplete detection of semi-automatic equipment, and achieve the effect of improving efficiency and improving factory yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

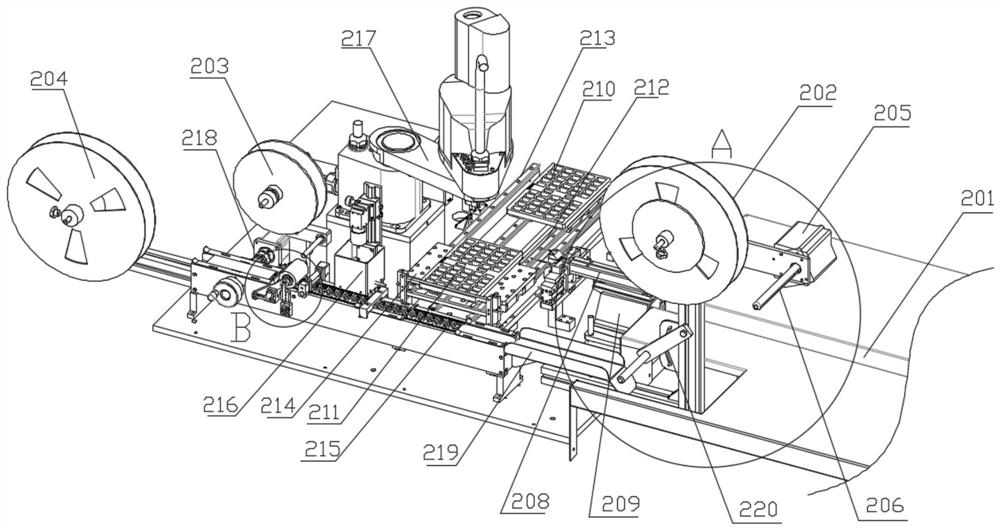

[0028] see Figure 1 to Figure 3 , Embodiment 1 of the present invention includes:

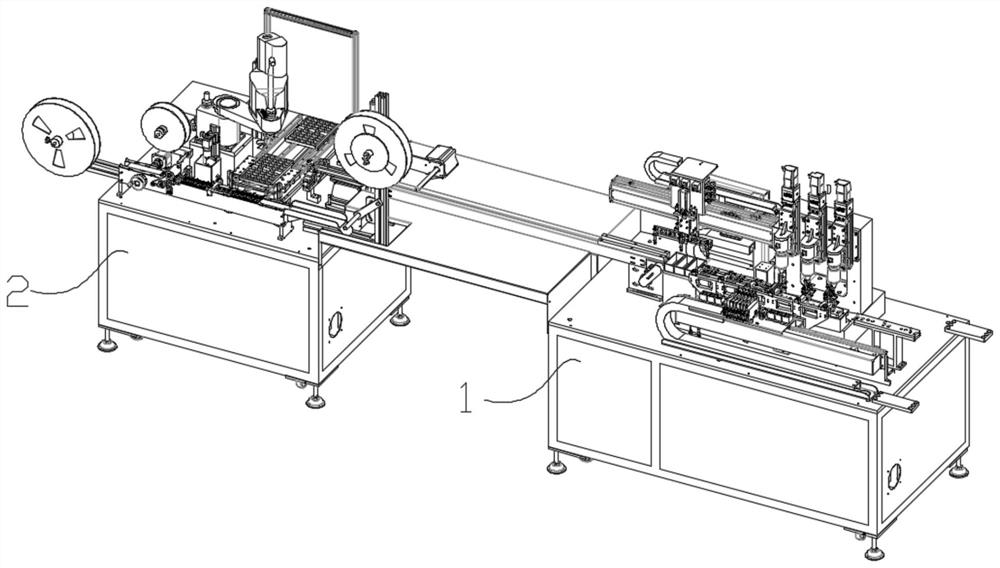

[0029] A board-to-board connector joint detection and packaging equipment, mainly including: detection section 1, packaging section 2, frame, control system and touch screen, the detection section 1, packaging section 2, control system and touch screen are respectively arranged on the machine shelf;

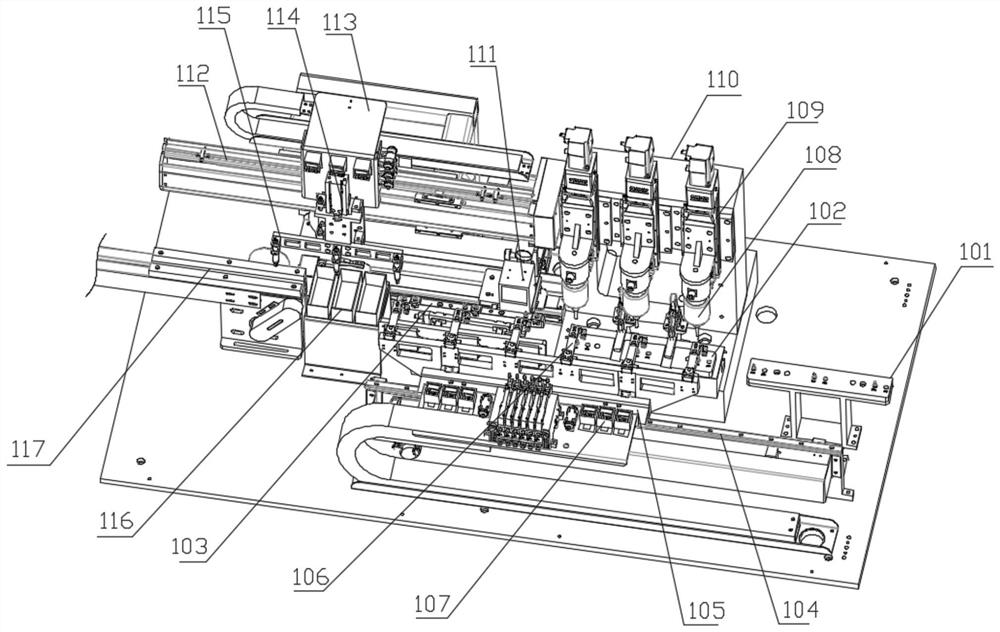

[0030] The detection section includes in turn: a feeding assembly, a detection assembly and a blanking assembly;

[0031] The feeding assembly includes: jig A101, jig B102, jig C103, guide rail A104, slider A105, and suction head 106, and the jig A101, jig B102, and jig C103 are arranged on a straight line. The guide rail A104 is arranged on the outside of the jig A101, the jig B102 and the jig C103. The slider A105 is arranged on the guide rail A104 and can slide along the guide rail A104. The suction head 106 is connected to the slider A105 and extends to the jig A105. Above the tool A101, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com