Paper pasting device and method of protective tube paper pasting forming machine

A technology of fuse tube and molding machine, which is applied in fuse manufacturing and other directions, can solve problems such as difficulty in sticking tape, and achieve the effects of light structure, improved conveying efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

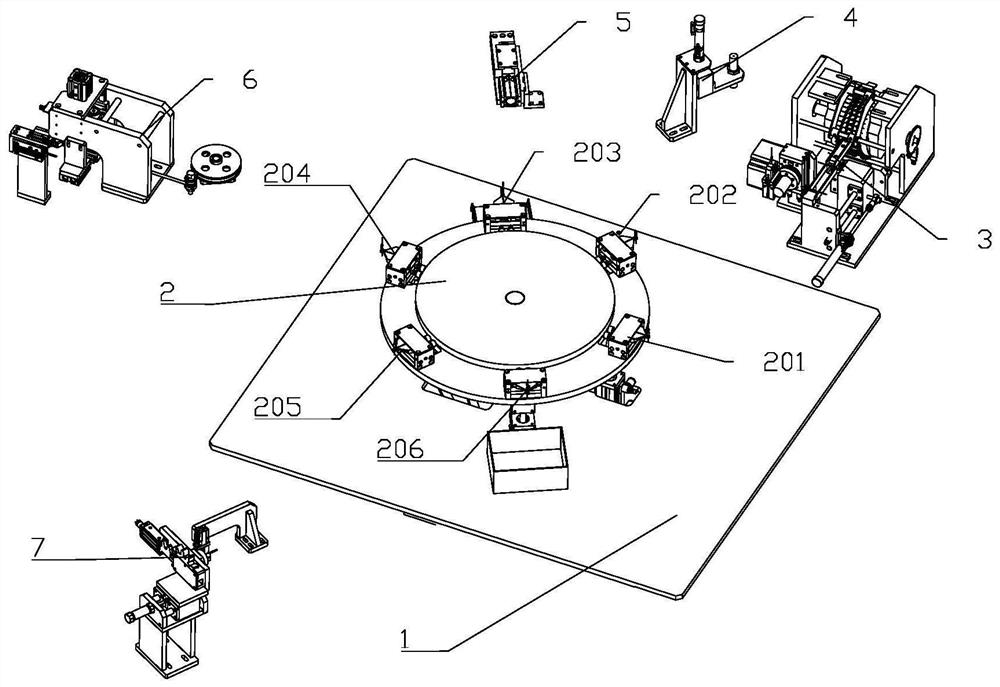

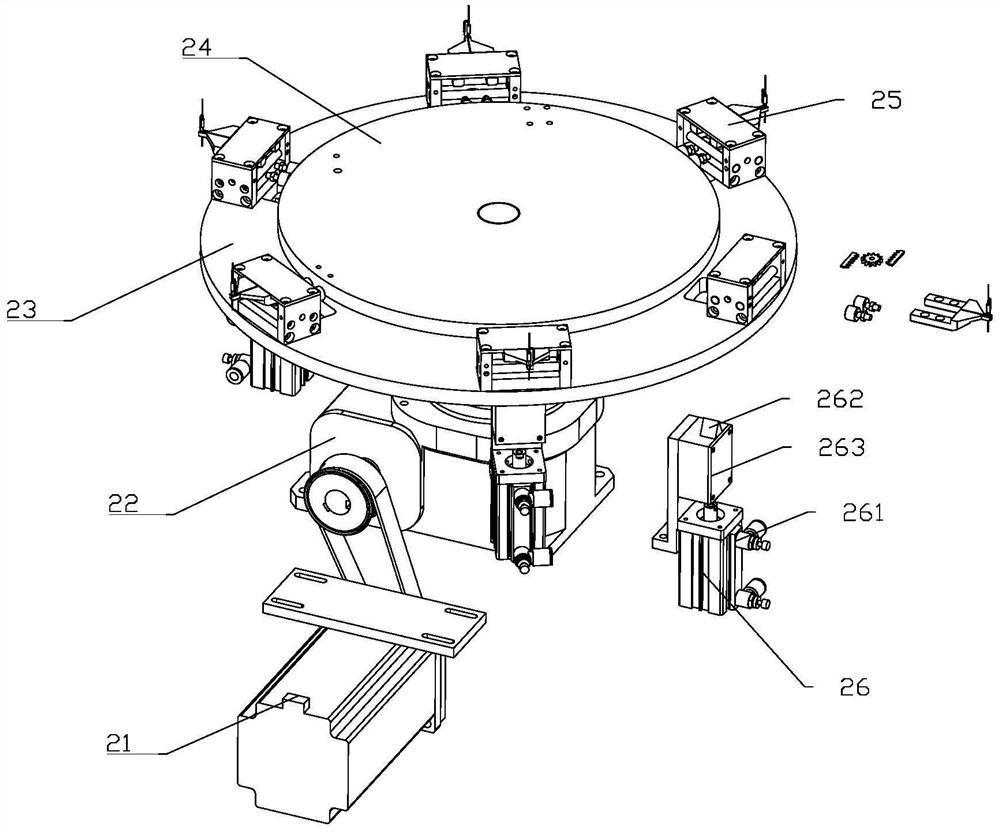

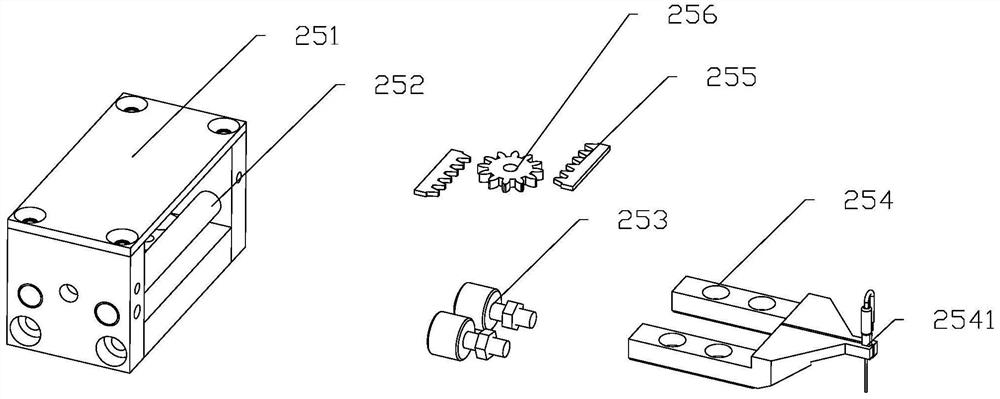

[0031] Such as figure 1 As shown, a fuse sticker forming machine includes a frame 1 and a rotating fixture device 2 installed on the frame 1, a strip dismantling device 3, a straightening device 4, a cutting device 5, a sticker device 6 and a bending device 7; the rotating fixture device 2 is installed in the middle of the frame 1, and the tape dismantling device 3, straightening device 4, cutting device 5, sticker device 6 and bending device 7 are arranged in a circle in sequence Rotate the outer periphery of fixture device 2; Described rotary fixture device 2 is provided with a plurality of stations, is respectively feeding station 201, straightening station 202, cutting station 203, sticker station 204, bending worker Position 205 and unloading station 206; described unbraiding device 3 corresponds to feeding station 201, described straightening device 4 corresponds to straightening station 202, and described cutting device 5 corresponds to cutting station 203, the sticker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com