Industrial wastewater combined utilization treatment device

A technology for treatment device and industrial wastewater, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as sludge floating, sludge disturbance, pollution, etc. The effect of easy cleaning and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

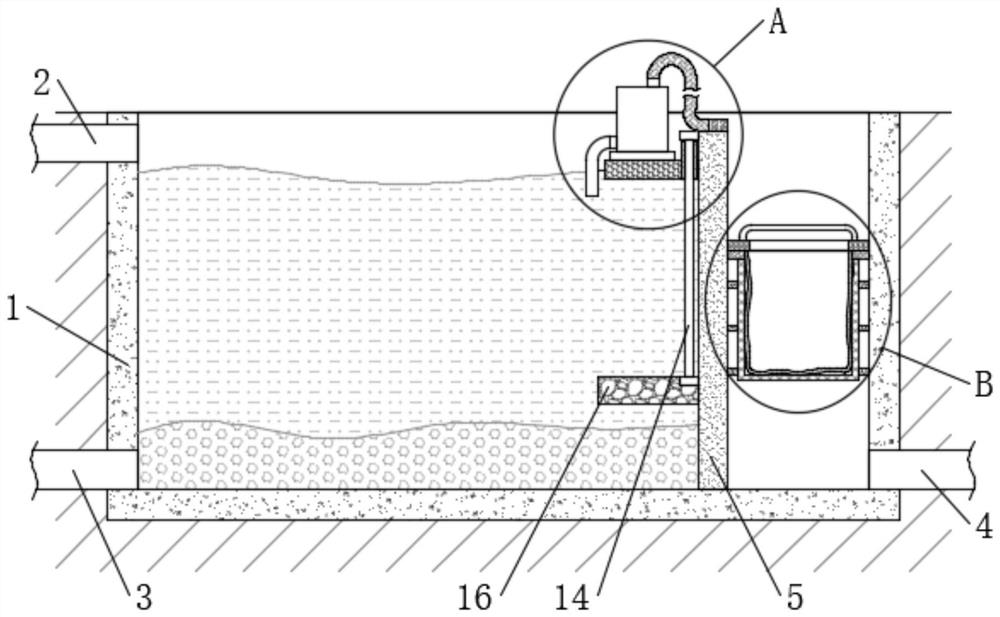

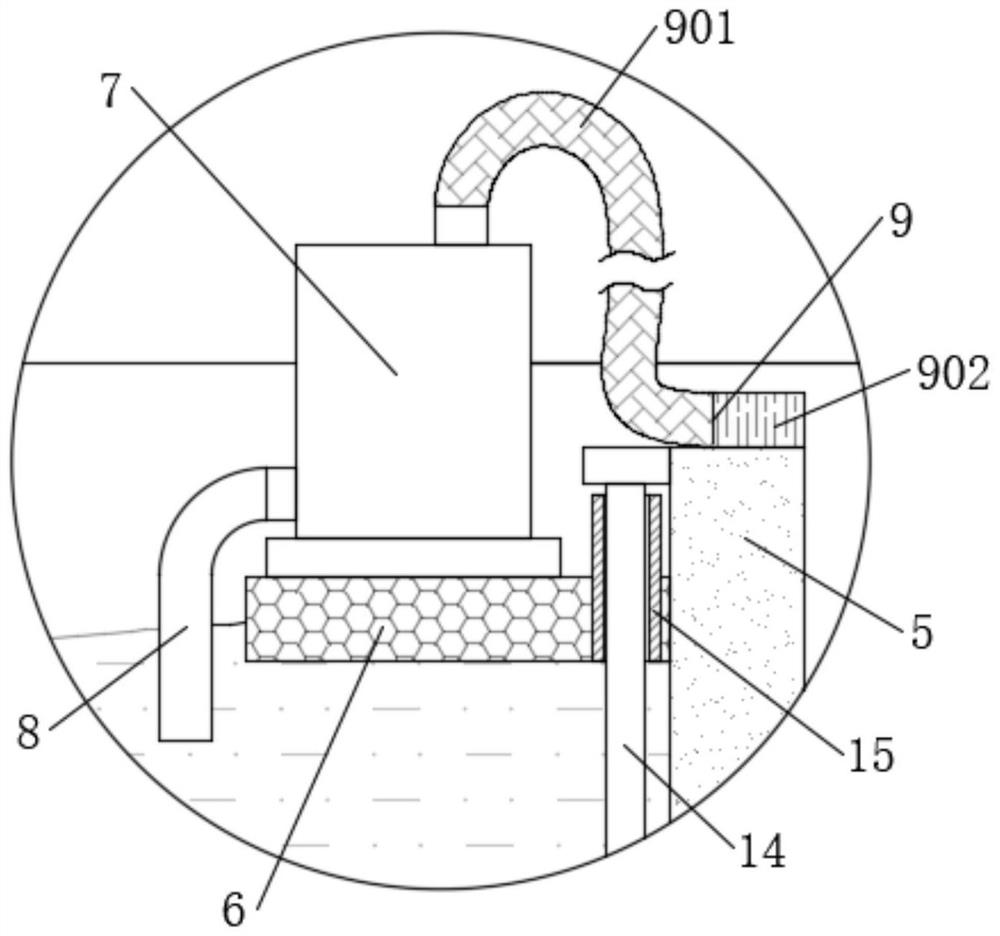

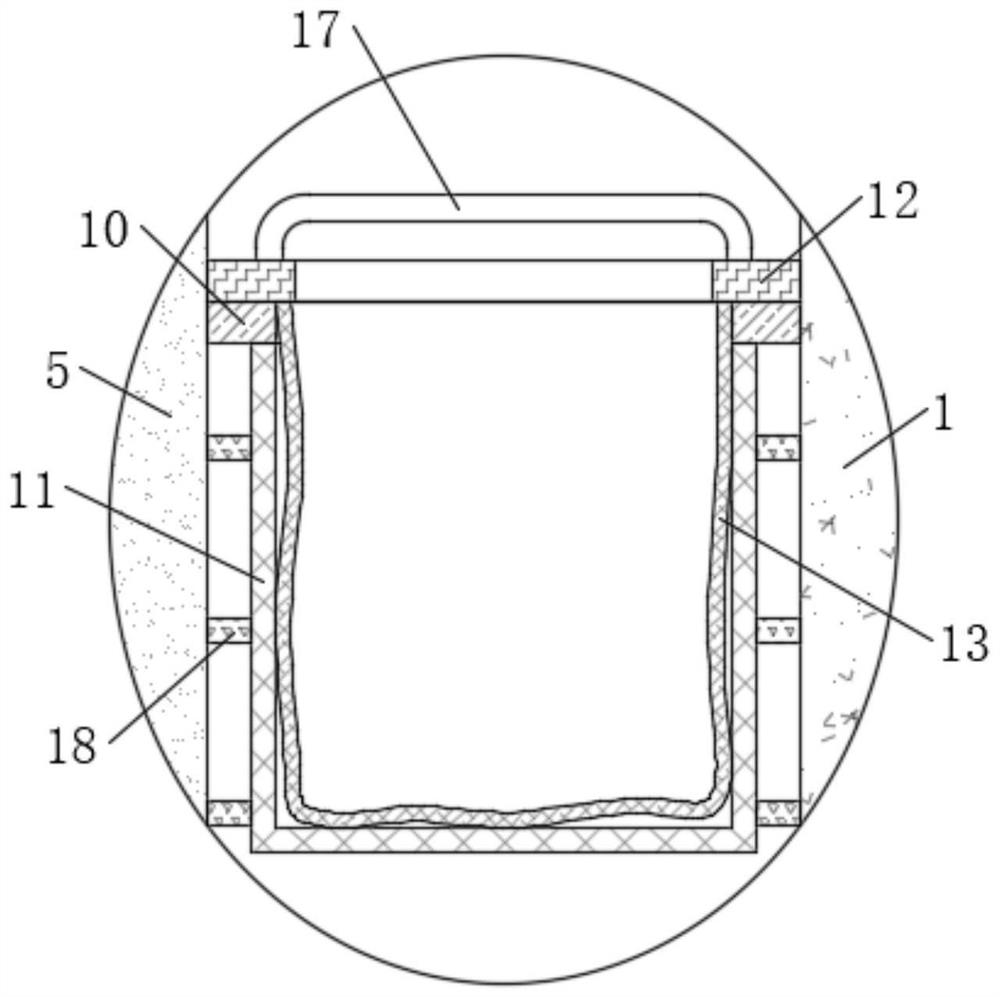

[0033] see figure 1 , an industrial waste water combined utilization treatment device, including a sedimentation tank 1, the left end of the sedimentation tank 1 is connected with a water inlet pipe 2 and a mud discharge pipe 3, and the water inlet pipe 2 is located on the upper side of the mud discharge pipe 3, and the right end of the sedimentation tank 1 is connected with an outlet pipe 4. The settling tank 1, the water inlet pipe 2, the mud discharge pipe 3 and the water outlet pipe 4 are all existing technologies, and will not be repeated here. The inside of the settling tank 1 is fixedly connected with a matching middle partition wall 5, and the middle partition wall 5 The inside of the sedimentation tank 1 can be divided into two compartments. The left side of the middle partition wall 5 is the sedimentation bin, and the mud-water mixture will be settled in the sedimentation bin. The right side of the middle partition wall 5 is the filter bin. Please refer to Figure 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com