Compressed air drying and purifying system

A purification system and compressed air technology, applied in the field of purification systems, can solve the problems of inability to collect and collect residues, poor sealing of the connection end position, and inability to collect and centrally process residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

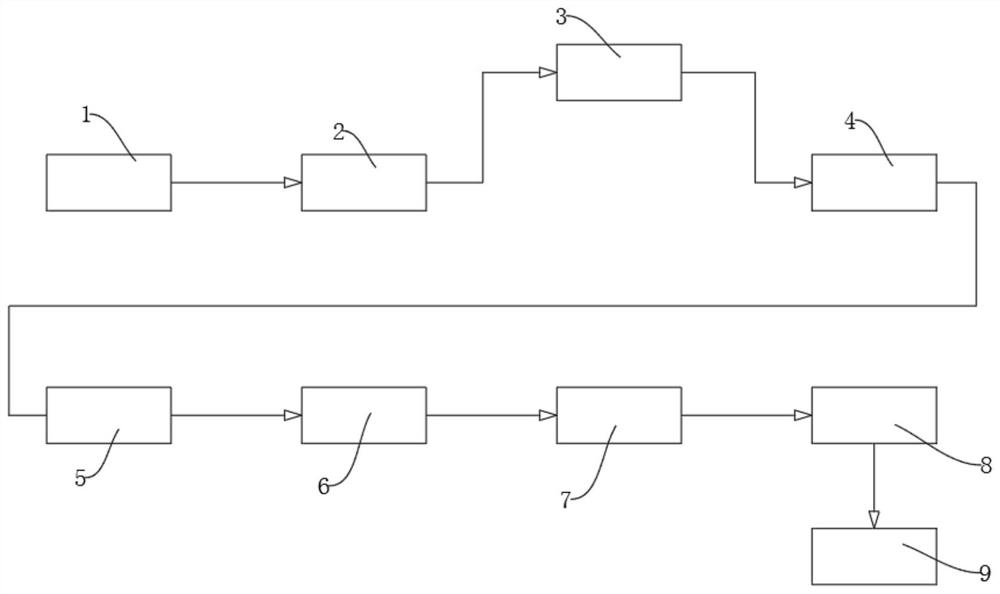

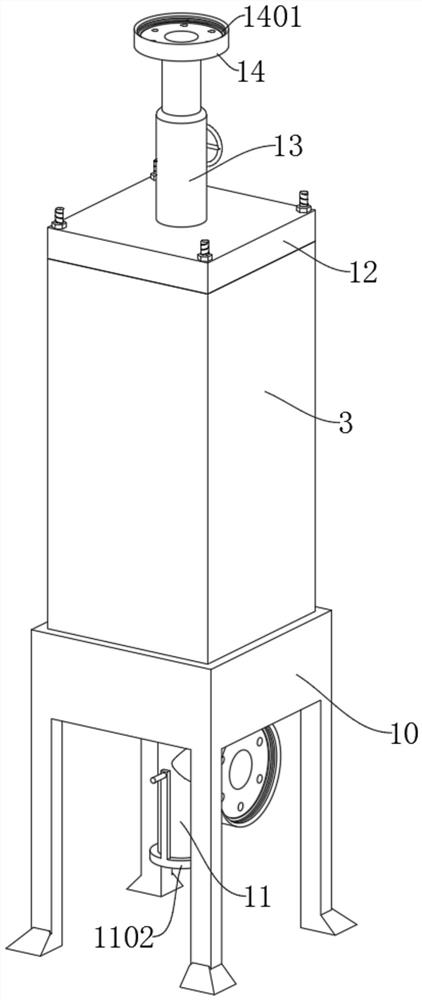

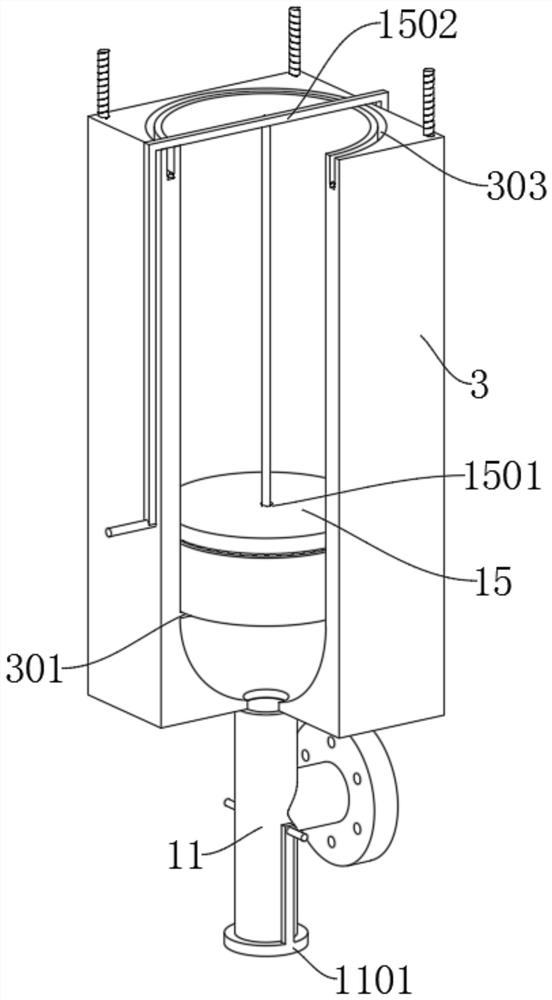

[0033] as attached figure 1 To attach Figure 10 Shown:

[0034] The present invention provides a compressed air drying and purification system, including: piston air compressor 1, cooler 2, oil-water separator 3, screw air compressor 4, buffer tank 5, U-level pre-filter 6, H-level Activated carbon micro-oil mist precision filter 7, air dryer 8 and F-class precision filter 9; piston air compressor 1 is equipped with cooler 2 off-line, and the off-line of cooler 2 is equipped with oil-water separator 3 (oil-water The separator is an S-class filter with a filtration efficiency > 99%, which can remove liquid water and oil. It is installed after the piston air compressor 1 for a preliminary oil-water separation); the oil-water separator 3 is equipped with screw air Compressor 4, and the off-line of the screw air compressor 4 is equipped with a buffer tank 5; the off-line of the buffer tank 5 is provided with a U-level pre-filter 6, and the off-line of the U-level pre-filter 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com