Cutter device of preservative film packaging machine

A packaging machine and plastic wrap technology, applied in the field of cutter device and plastic wrap packaging machine, can solve the problems of complex power device, difficult control of depth, and low packaging efficiency, so as to ensure smooth movement, low manufacturing cost, and high-efficiency cutting and packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

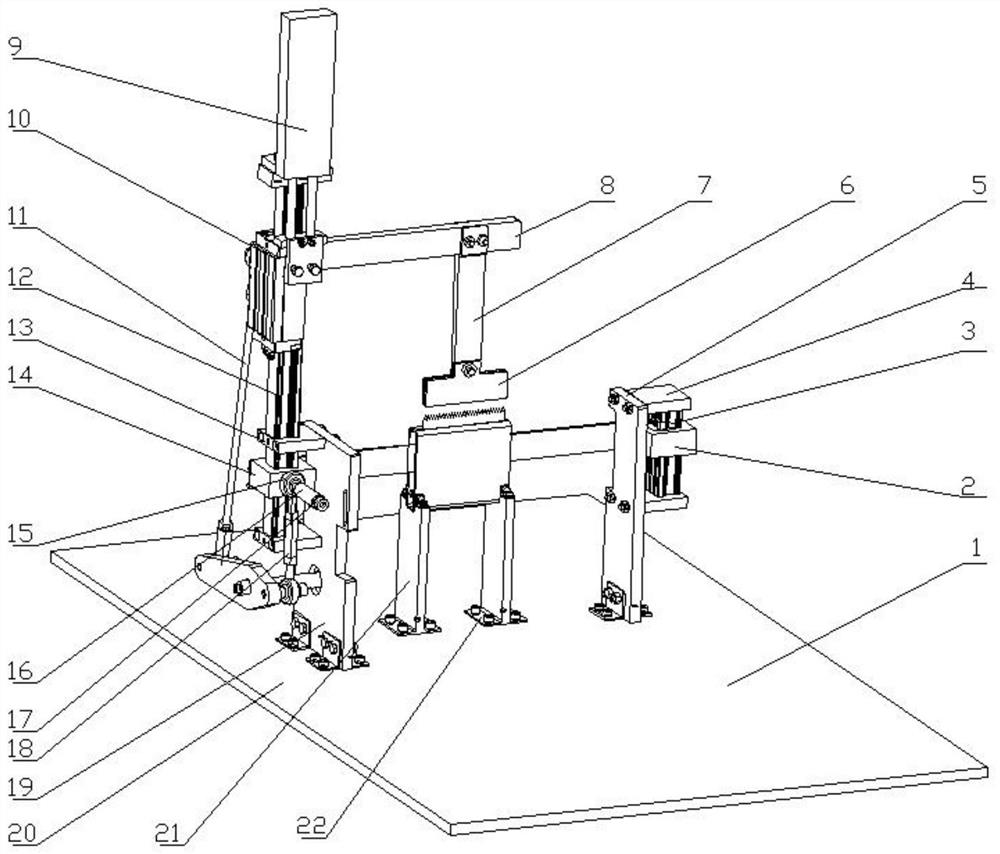

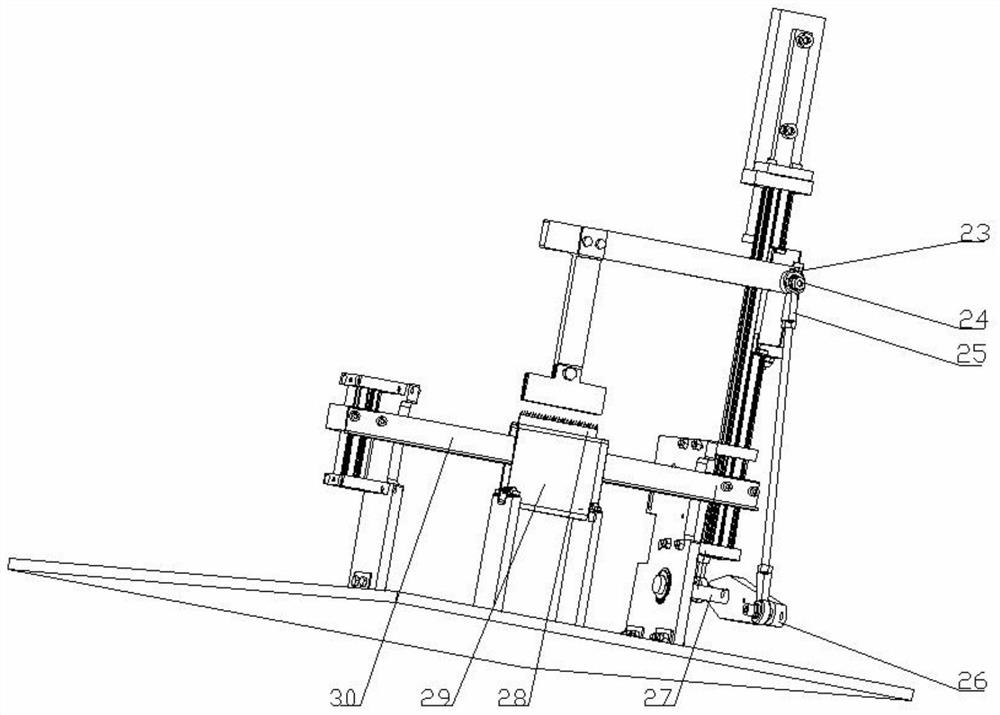

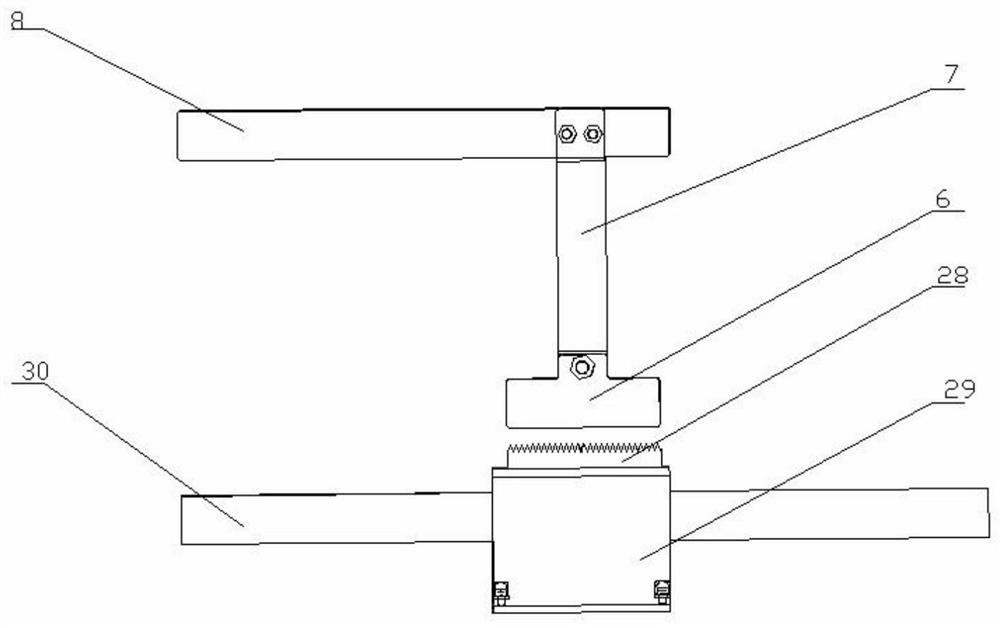

[0028] A cutter device of a plastic wrap packaging machine, which is innovative in that it includes a frame 1, a cutter unit and a drive unit, the frame includes a base 20, a left support plate 19 and a right support plate 5; the cutter The knife unit includes a left slide assembly and a right slide assembly, the left slide assembly includes a left guard plate 13, a left slide rail 12 and a left slide block 14, and two left guard guards are arranged vertically and symmetrically on the outer wall of the left support plate. plate, the left sliding rail is set between the two left protective plates, the left slider is slidably installed on the left sliding rail, and the right sliding assembly includes the right protective plate 4, the right slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com