Orange feeding device

A technology for tangerines and material transportation, applied in the field of tangerine feeding devices, can solve the problems of easy fatigue of workers in operation, low efficiency of tangerine peeling, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

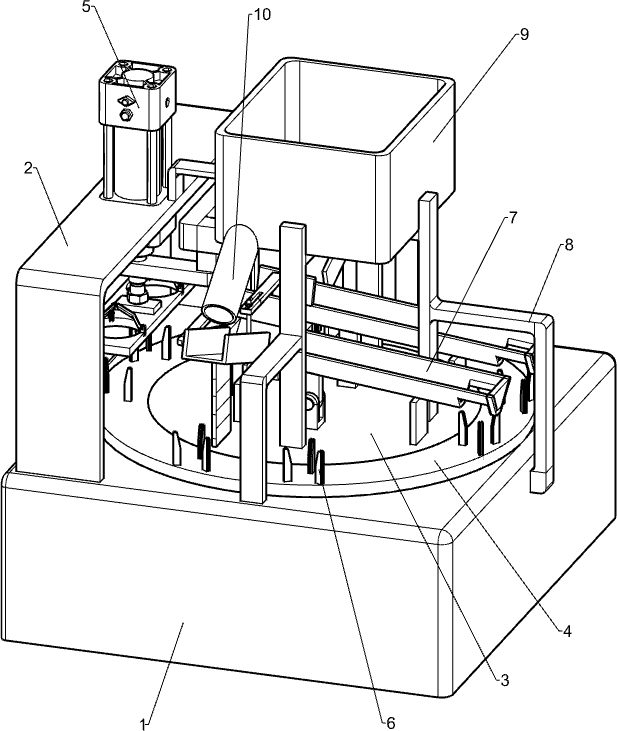

[0040] A kind of tangerine feeding device, such as figure 1 with Figure 4 As shown, it includes a base 1, a first support frame 2, a mounting disc 3, a rotating disc 4, a cylinder 5, a collection frame 6, a feeding mechanism 7, a second support frame 8, a pressing rod 12, and a cutting plate 13 , reduction motor 14 and second connecting rod 15, base 1 left side is provided with first support frame 2, and first support frame 2 top center is equipped with cylinder 5, and the front side, rear side and left side of base 1 are all installed There is a second support frame 8, the inner bottom of the second support frame 8 is provided with an installation disc 3, the base 1 is rotatably provided with a rotating disc 4, the rotating disc 4 is located outside the installation disc 3, and the rotating disc 4 is evenly provided with Collector 6, the top of disc 3 is connected with feeding mechanism 7, the telescoping rod of cylinder 5 is provided with pressure rod 12, the bottom of tel...

Embodiment 2

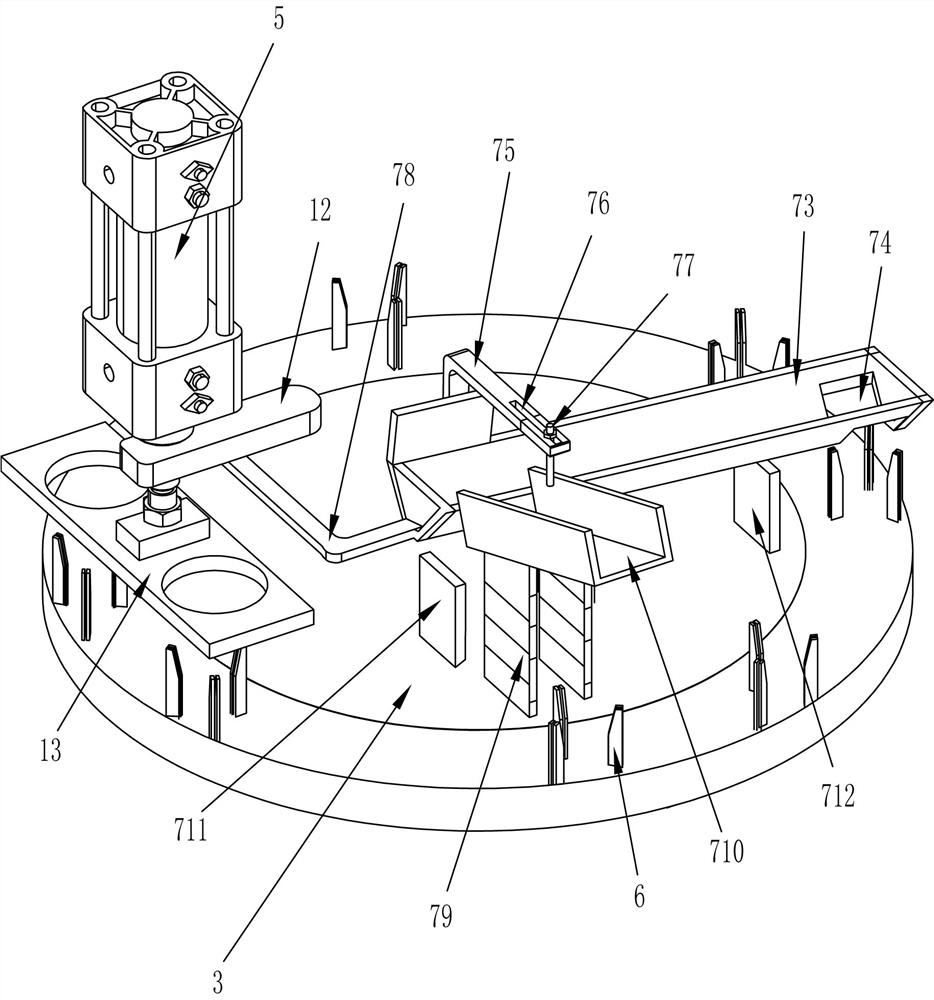

[0043] based on Figure 1-3 , the feeding mechanism 7 includes a mounting seat 71, a rotating rod 72, a guide rail 73, an L-shaped rod 75, a stop rod 77, a first connecting rod 78, a riser 79, a chute 710, a first stop 711 and a second stop Block 712, install disc 3 central part front and back both sides symmetrical formula to be provided with mounting base 71, mounting base 71 tops are all rotatably connected rotating rod 72, and guide rail 73 is installed on the top of rotating rod 72, and the right part of both sides guide rail 73 all has Feeding hole 74, L-shaped bar 75 is installed on the left side of both sides guide rails 73 close to each other, the top front side of front side L-shaped bar 75 and the top rear side of rear side L-shaped bar 75 all have chute 76, the chute 76 is fixed with a retaining rod 77 by bolts, and the first connecting rod 78 is connected between the left parts of the guide rails 73 on the front and rear sides, and the first connecting rod 78 is l...

Embodiment 3

[0046] as special reference figure 1 , image 3 with Figure 5 As can be seen from the diagram, it also includes a material frame 9 and a feeding pipe 10, a material frame 9 is installed between the top of the second support frame 8, and a feeding pipe 10 is provided on the lower left side of the front wall and the rear wall of the material frame 9, The ends of the feeding pipes 10 on both sides are located above the feeding chute 710 .

[0047] Manually oranges are poured into the material frame 9, and the oranges drop into the feed chute 710 along the feeding pipe 10 on both sides of the material frame 9, without manually placing the oranges in the feed chute 710.

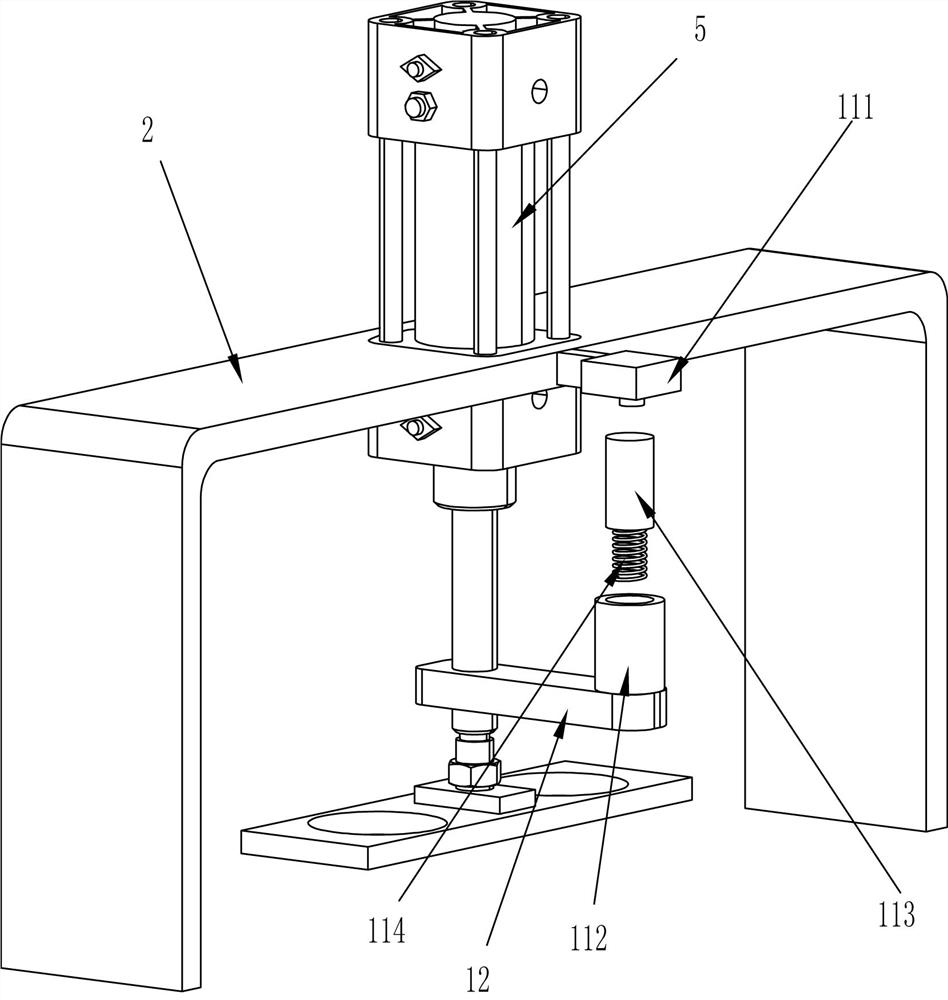

[0048] Also includes a starting mechanism 11, the starting mechanism 11 includes a control switch 111, a support cylinder 112, a pressure block 113 and a spring 114, a control switch 111 is installed in the middle of the upper right side of the first support frame 2, and a support is provided on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com