Magnesium-based hydrogen desorption material, preparation method thereof and hydrolysis hydrogen production method

A hydrogen material, magnesium hydride technology, applied in the production of hydrogen, chemical instruments and methods, alkali metal/alkaline earth metal/beryllium/magnesium hydride, etc., can solve the problem of low hydrolysis reaction rate and conversion rate, and damage to the continuity of hydrolysis reaction , insoluble in water and other issues, to achieve the effect of large hydrogen production, sustainable hydrogen desorption, and high hydrolysis conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

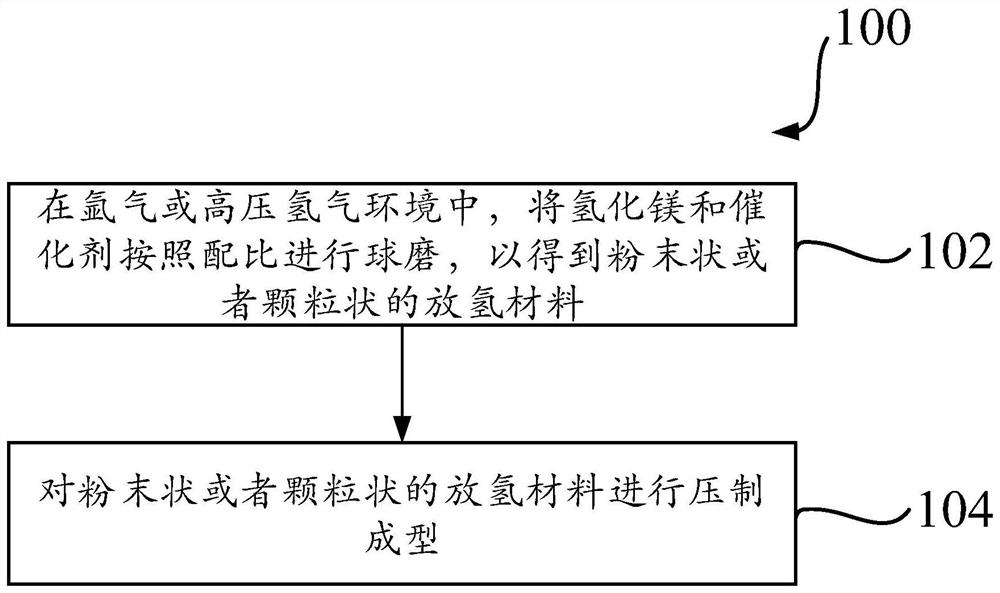

Method used

Image

Examples

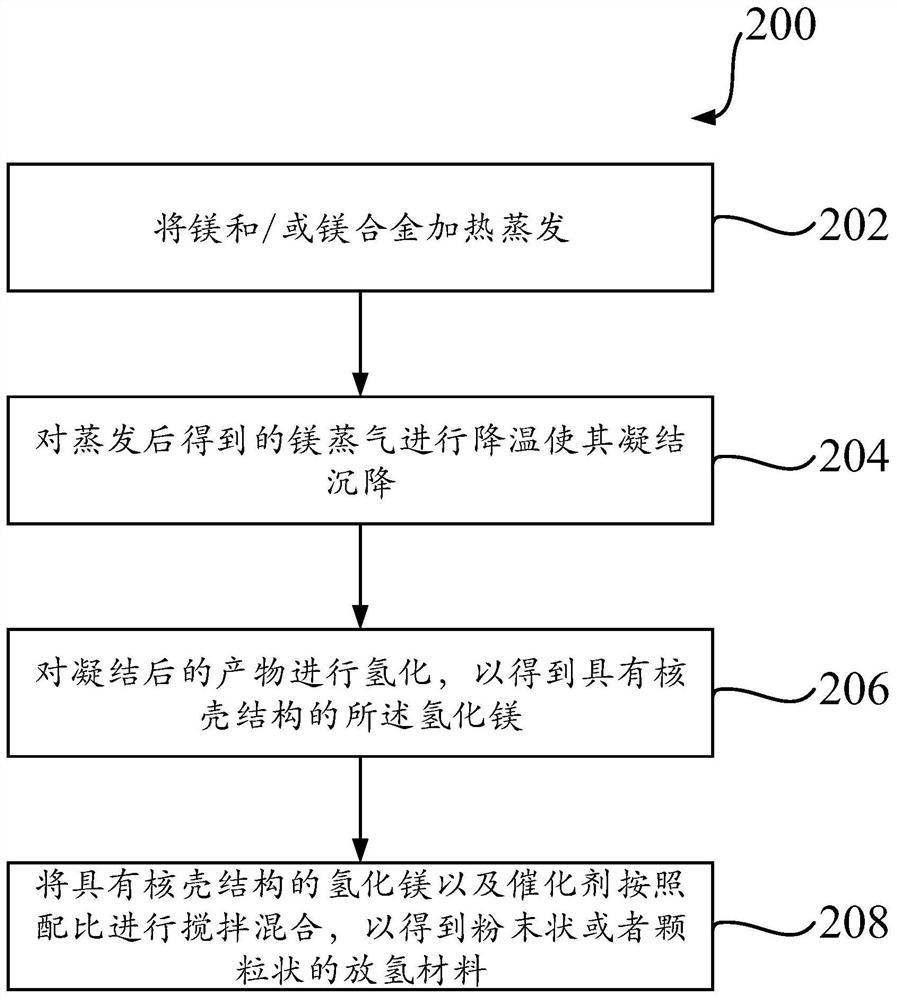

Embodiment 1

[0083] Embodiment 1: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of titanium dioxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and titanium dioxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350 ° C, and the hydrogen pressure is 3.0 MPa. The time is 4 hours, the stirring speed of stirring and mixing is 400 rpm, and the stirring time is 30 minutes.

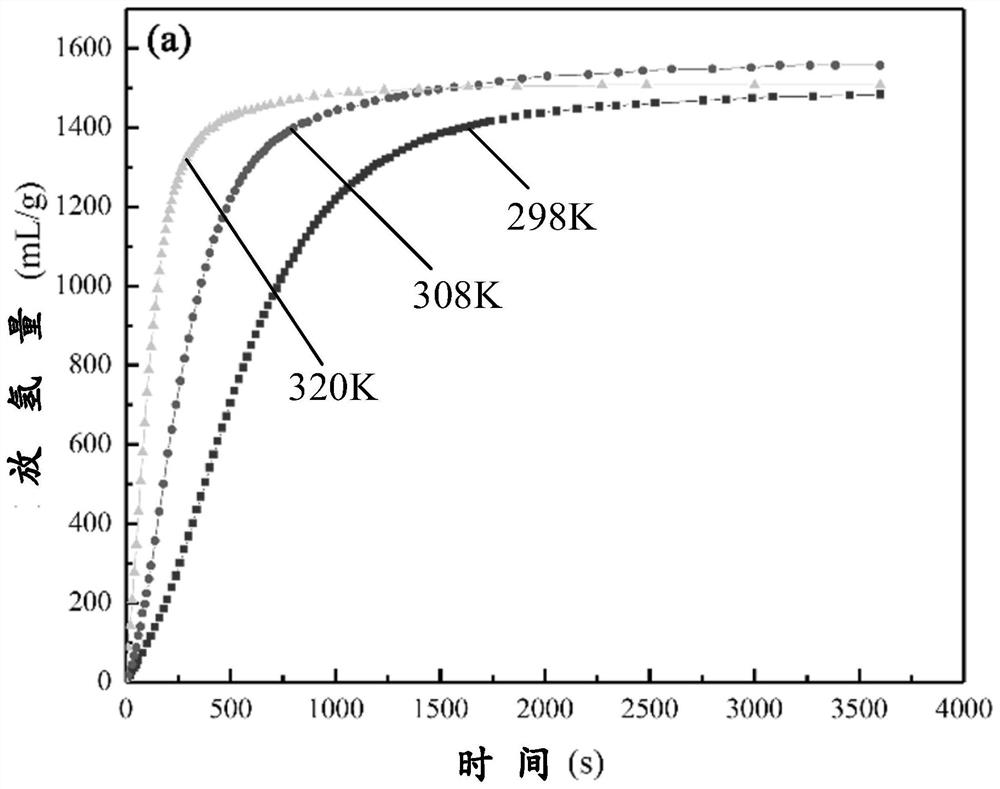

[0084] Figure 3a-Figure 3b It is a schematic diagram of the results of the hydrolysis hydrogen release test ...

Embodiment 2

[0086] Embodiment 2: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of aluminum oxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and aluminum sesquioxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350°C and the hydrogen pressure is 3.0MPa , the hydrogenation time is 4h, the stirring speed of stirring and mixing is 300 rpm, and the stirring time is 1h.

[0087] Figure 4a-Figure 4b It is a schematic diagram of the results of the hydrolysis hydrogen release test ...

Embodiment 3

[0089] Embodiment 3: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of ferric oxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and ferric oxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350°C and the hydrogen pressure is 3.0MPa , the hydrogenation time is 4h, the stirring speed of stirring and mixing is 350 rpm, and the stirring time is 40min.

[0090] Figure 5a-Figure 5b It is a schematic diagram of the results of the hydrolysis hydrogen release test at diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com