Magnesium-based hydrogen-releasing material, method for its preparation, and method for producing hydrogen by hydrolysis

A hydrogen material, magnesium hydride technology, applied in the production of hydrogen, chemical instruments and methods, alkali metal/alkaline earth metal/beryllium/magnesium hydride, etc., can solve the problem of low hydrolysis reaction rate and conversion rate, insoluble in water, Destroying the continuity of the hydrolysis reaction and other issues, achieving the effect of large hydrogen production, high hydrolysis conversion rate, and sustainable hydrogen release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

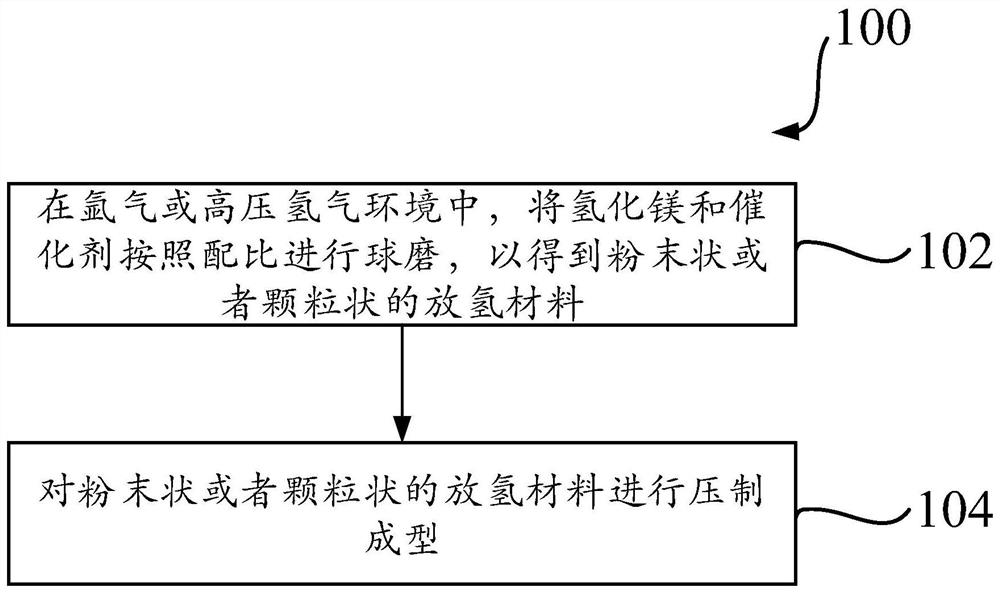

Method used

Image

Examples

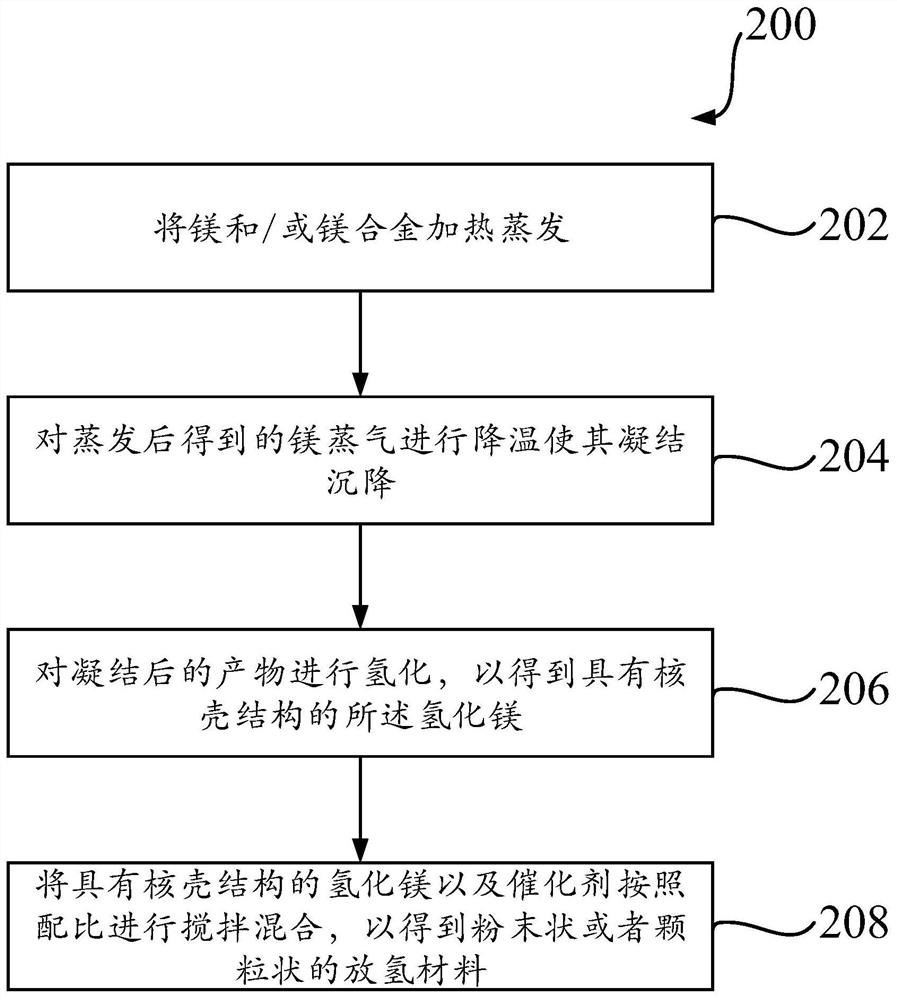

Embodiment 1

[0083] Embodiment 1: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of titanium dioxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and titanium dioxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350 ° C, and the hydrogen pressure is 3.0 MPa. The time is 4 hours, the stirring speed of stirring and mixing is 400 rpm, and the stirring time is 30 minutes.

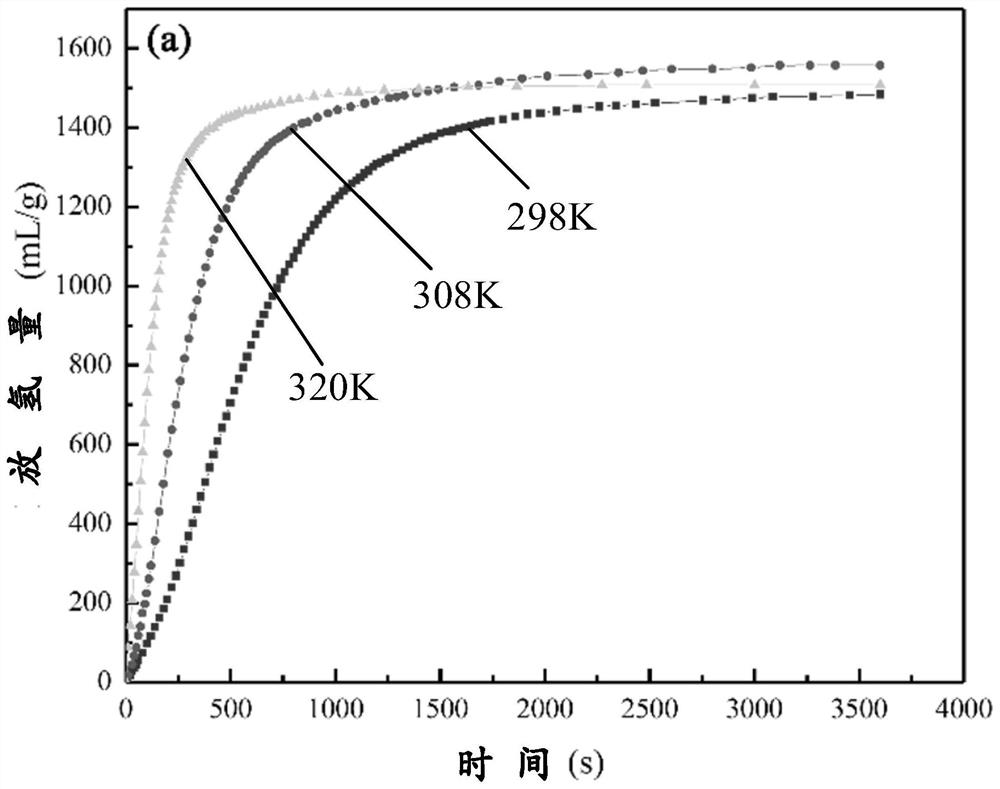

[0084] Figure 3a-Figure 3b It is a schematic diagram of the results of the hydrolysis hydrogen release test ...

Embodiment 2

[0086] Embodiment 2: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of aluminum oxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and aluminum sesquioxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350°C and the hydrogen pressure is 3.0MPa , the hydrogenation time is 4h, the stirring speed of stirring and mixing is 300 rpm, and the stirring time is 1h.

[0087] Figure 4a-Figure 4b It is a schematic diagram of the results of the hydrolysis hydrogen release test ...

Embodiment 3

[0089] Embodiment 3: The composition and mass ratio of the hydrogen-releasing material in this embodiment are respectively: 45 parts of magnesium hydride and 5 parts of ferric oxide. The preparation method of the hydrogen-releasing material in this embodiment is as follows: heating and evaporating the magnesium arc; cooling the evaporated magnesium vapor to condense and settle; hydrogenating the condensed product to obtain the hydrogenated product with a core-shell structure Magnesium; and stirring and mixing magnesium hydride with a core-shell structure and ferric oxide according to the ratio to obtain the hydrogen-releasing material in powder or granular form, wherein the hydrogenation temperature is 350°C and the hydrogen pressure is 3.0MPa , the hydrogenation time is 4h, the stirring speed of stirring and mixing is 350 rpm, and the stirring time is 40min.

[0090] Figure 5a-Figure 5b It is a schematic diagram of the results of the hydrolysis hydrogen release test at diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com