Dehumidification system used for inhaul cable protection, anchoring and air inflow

A protective cover and air intake pipe technology, applied to bridge parts, bridge erection/assembly, measuring devices, etc., can solve potential safety hazards, hinder traffic operations, etc., prevent oxidation and corrosion, improve service life, and save maintenance and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

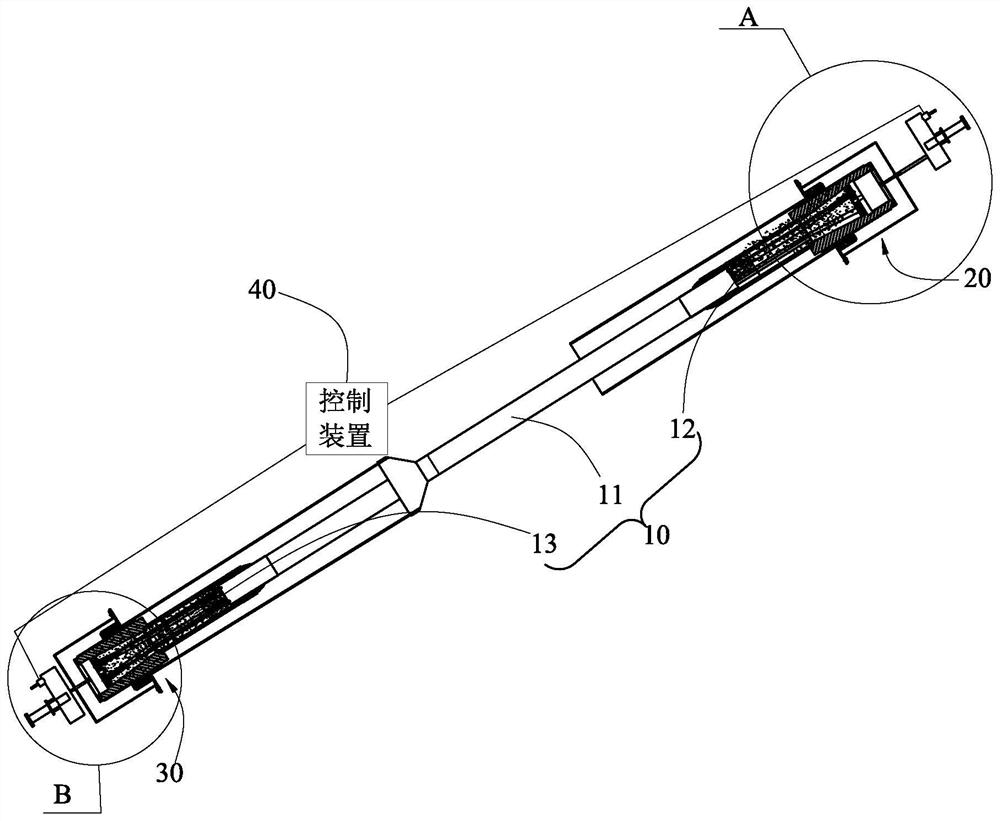

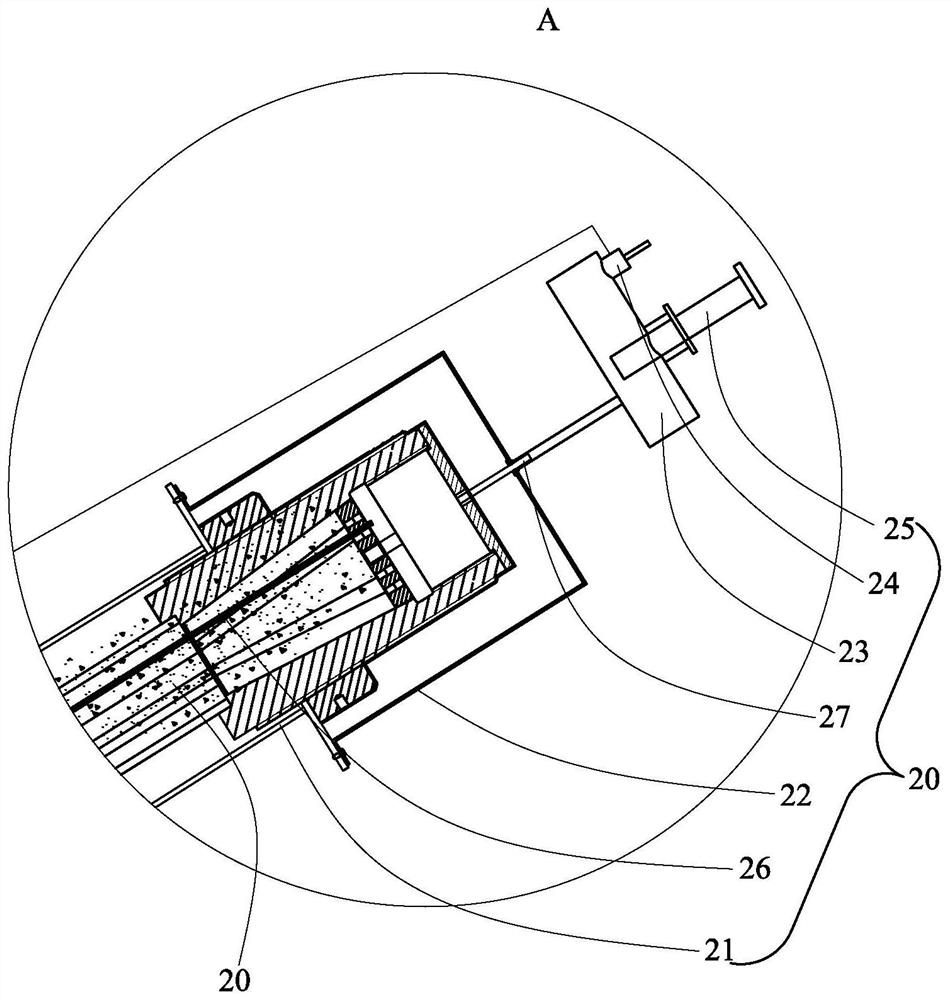

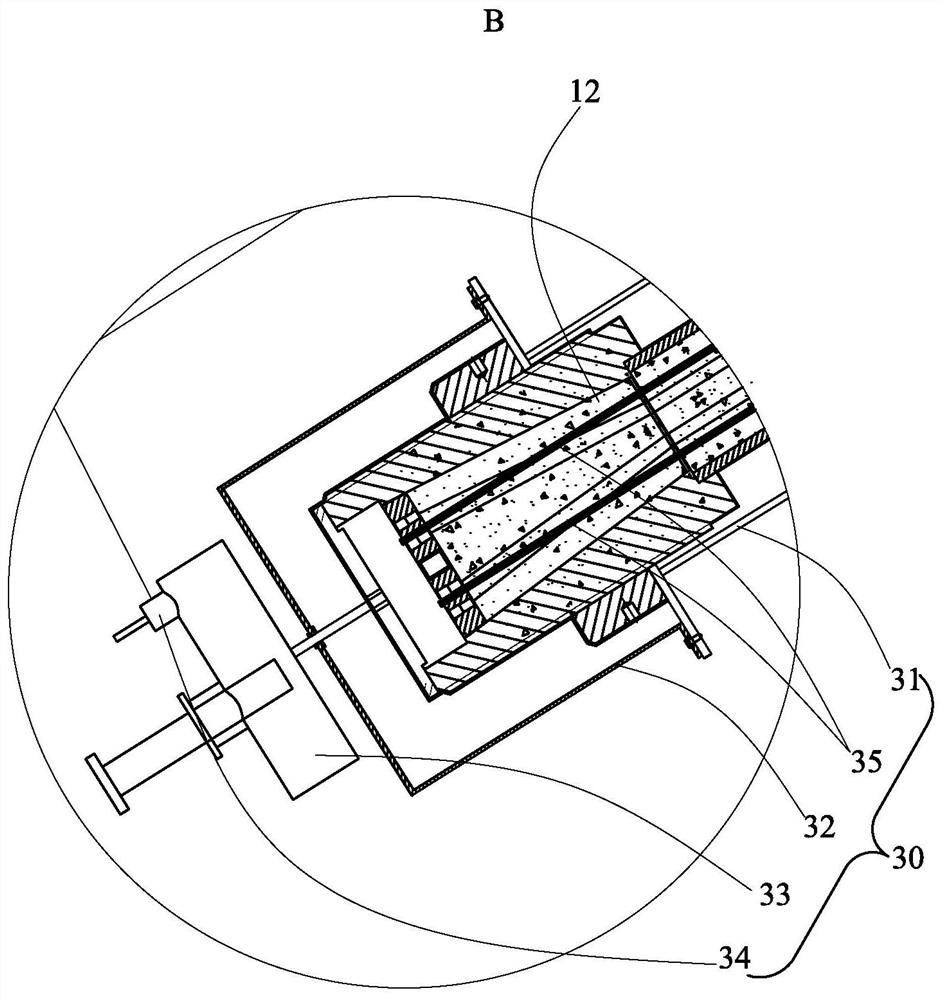

[0019] Such as Figure 1 to Figure 3 As shown, it is a schematic structural diagram of the dehumidification system used for cable protection and anchoring air intake provided by the present invention. The dehumidification system used for cable protection and anchoring air intake includes a cable body 10, an upper anchor protection mechanism 20 arranged on the cable body 10, and an upper anchor protection mechanism 20 arranged on the cable body 10. The lower anchor protection mechanism 30, and a control device 40 electrically connected with the upper and lower anchor protection mechanisms 20, 30. It is conceivable that the dehumidification system used for cable protection and anchoring air intake also includes other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com