Horizontal-type steam turbine condenser

A technology for condensers and steam turbines, applied in steam/steam condensers, non-rotating equipment cleaning, cleaning heat transfer devices, etc., can solve problems such as inability to eliminate supercooling, increase energy consumption, and increase cooling water consumption, etc., to achieve Avoid the increase of oxygen capacity, prevent clogging, and save dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

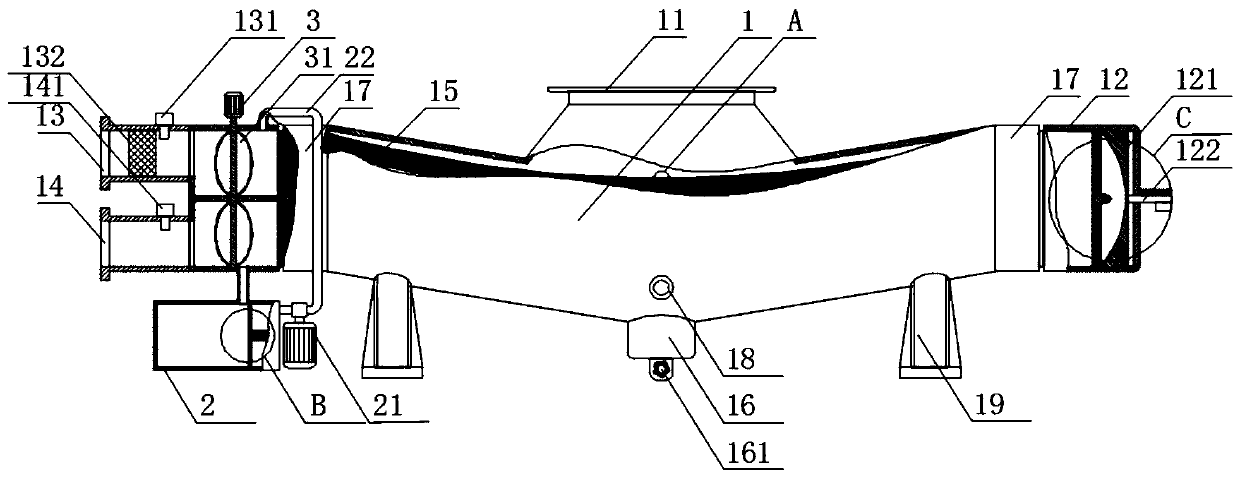

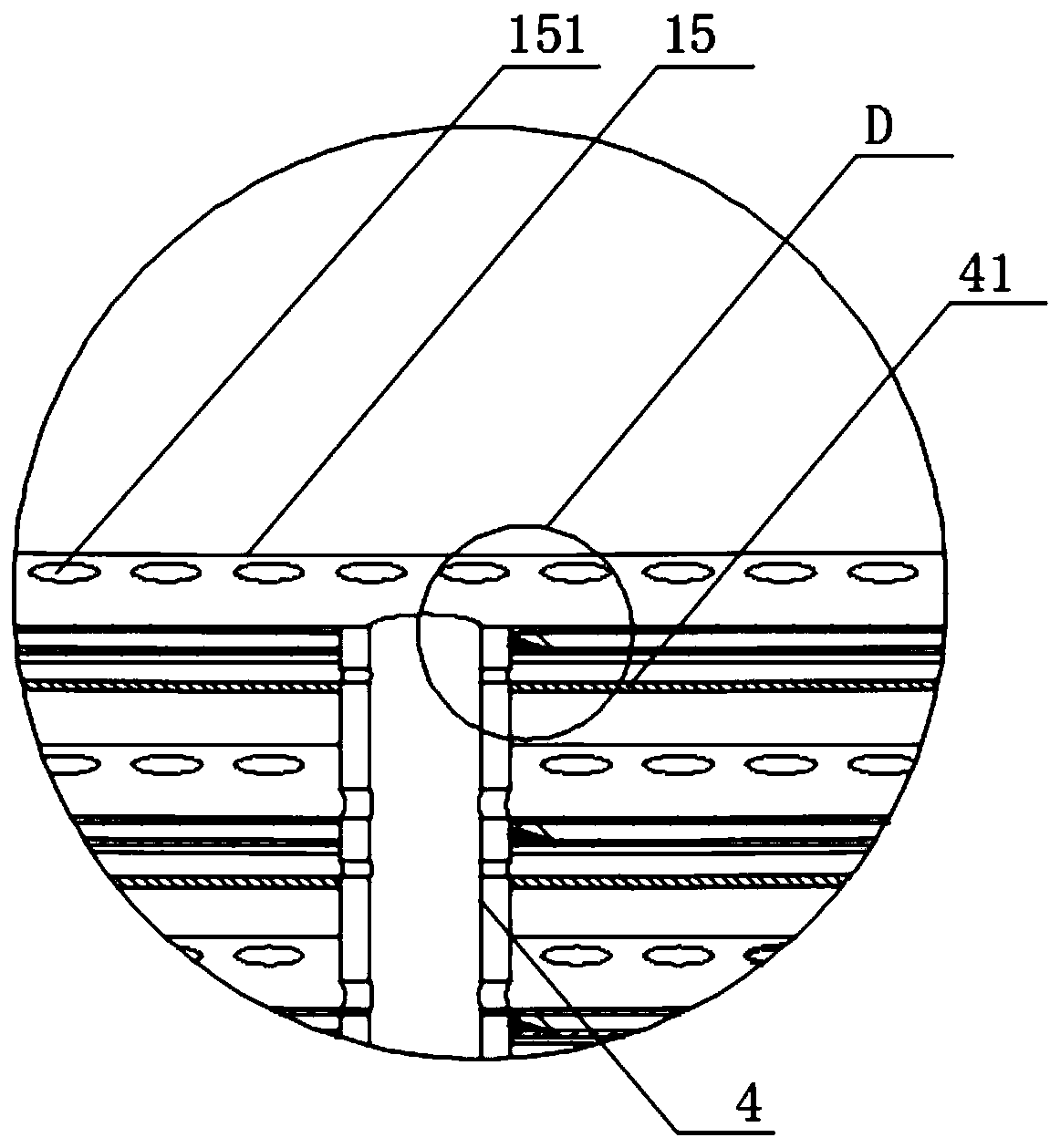

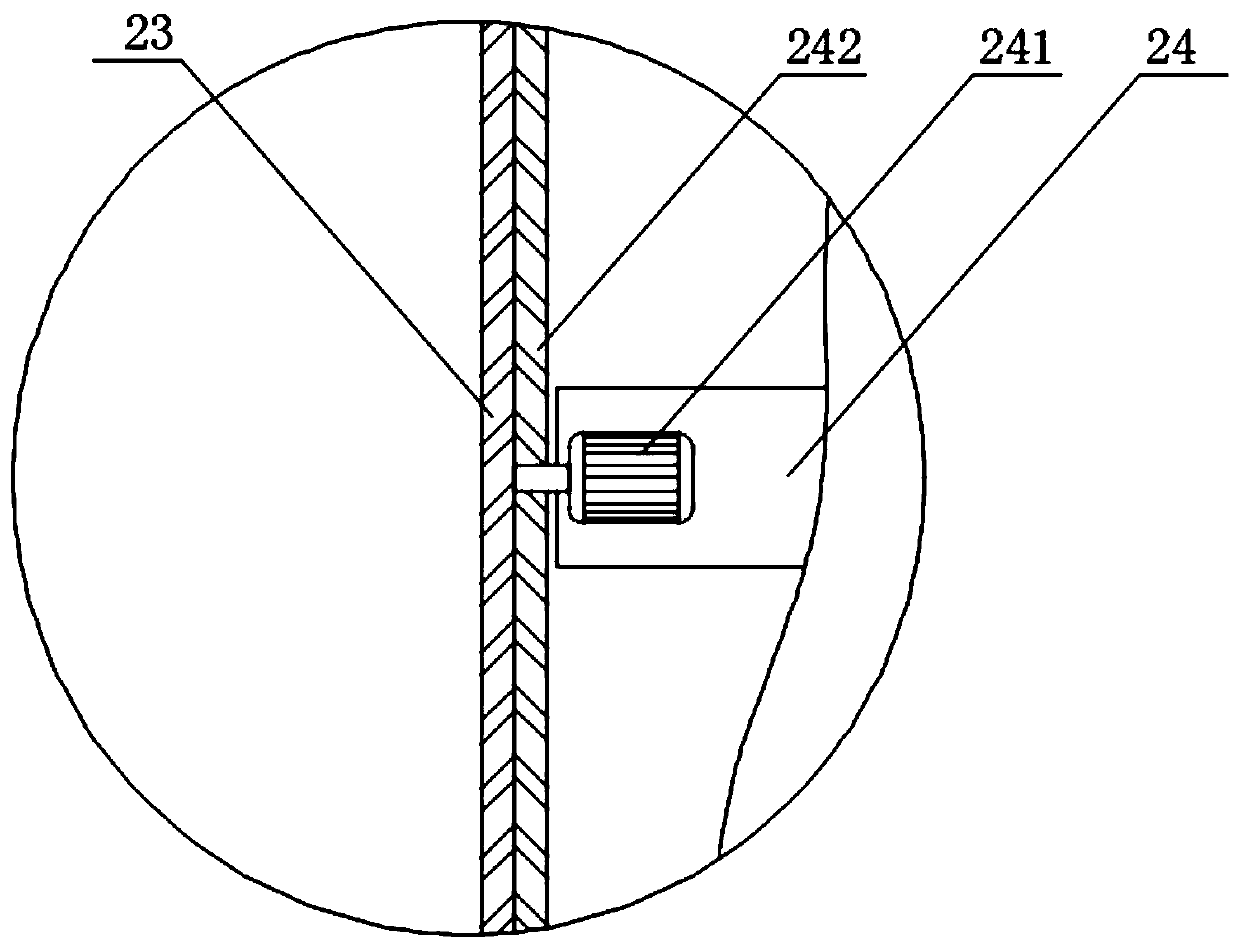

[0033] Example 1, see Figure 1-2 , 7-8, the present invention provides a technical solution: a horizontal steam turbine condenser, comprising a condenser cylinder 1, a throat 11, a support 19 and a cooling water pipe 15, the top of the condenser cylinder 1 The throat 11 is connected in the middle, and the bottom end is fixedly connected with supports 19 near both ends. The tube plate 17 is connected to both sides of the condenser cylinder 1, and the tube plate 17 on the left side of the condenser cylinder 1 The outer side is connected with a cooling water inlet chamber 13 and a cooling water outlet chamber 14, the tube sheet 17 on the right side of the condenser cylinder 1 is connected with a return water chamber end cover 12, and a cooling water pipe 15 is connected between the tube sheets 17, and the condensing steam A hot well 16 is arranged at the center of the bottom end of the condenser cylinder 1, and a condensed water outlet 161 is arranged at the bottom end of the he...

Embodiment 2

[0035] Example 2, see Figure 1-9 , the present invention provides a technical solution: a horizontal steam turbine condenser, comprising a condenser cylinder 1, a throat 11, a support 19 and a cooling water pipe 15, the top of the condenser cylinder 1 is connected to a Throat 11, and the bottom end near both ends is fixedly connected with support 19, both sides of condenser cylinder 1 are connected with tube plate 17, and the outer side of tube plate 17 on the left side of condenser cylinder 1 is connected with cooling The water inlet chamber 13 and the cooling water outlet chamber 14, the tube plate 17 on the right side of the condenser cylinder 1 is connected with the return water chamber end cover 12, the cooling water pipe 15 is connected between the tube plates 17, the condenser cylinder 1 A hot well 16 is arranged at the center of the bottom end of the hot well 16, and the bottom end of the hot well 16 is provided with a condensed water outlet 161, an air extractor 18 i...

Embodiment 3

[0037] Example 3, see figure 1 , 3 , 6, 9, the present invention provides a technical solution: a horizontal steam turbine condenser, comprising a condenser cylinder 1, a throat 11, a support 19 and a cooling water pipe 15, the top of the condenser cylinder 1 The throat 11 is connected in the middle, and the bottom end is fixedly connected with supports 19 near both ends. The tube plate 17 is connected to both sides of the condenser cylinder 1, and the tube plate 17 on the left side of the condenser cylinder 1 The outer side is connected with a cooling water inlet chamber 13 and a cooling water outlet chamber 14, the tube sheet 17 on the right side of the condenser cylinder 1 is connected with a return water chamber end cover 12, and a cooling water pipe 15 is connected between the tube sheets 17, and the condensing steam A hot well 16 is arranged at the center of the bottom of the condenser cylinder 1, and a condensed water outlet 161 is provided at the bottom of the heat we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com