Self-disinfection draught fan and fan with disinfection function

A fan and fan technology, applied in the field of fans with disinfection function, can solve problems such as air flow resistance, and achieve the effects of smooth air intake, wide application range and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

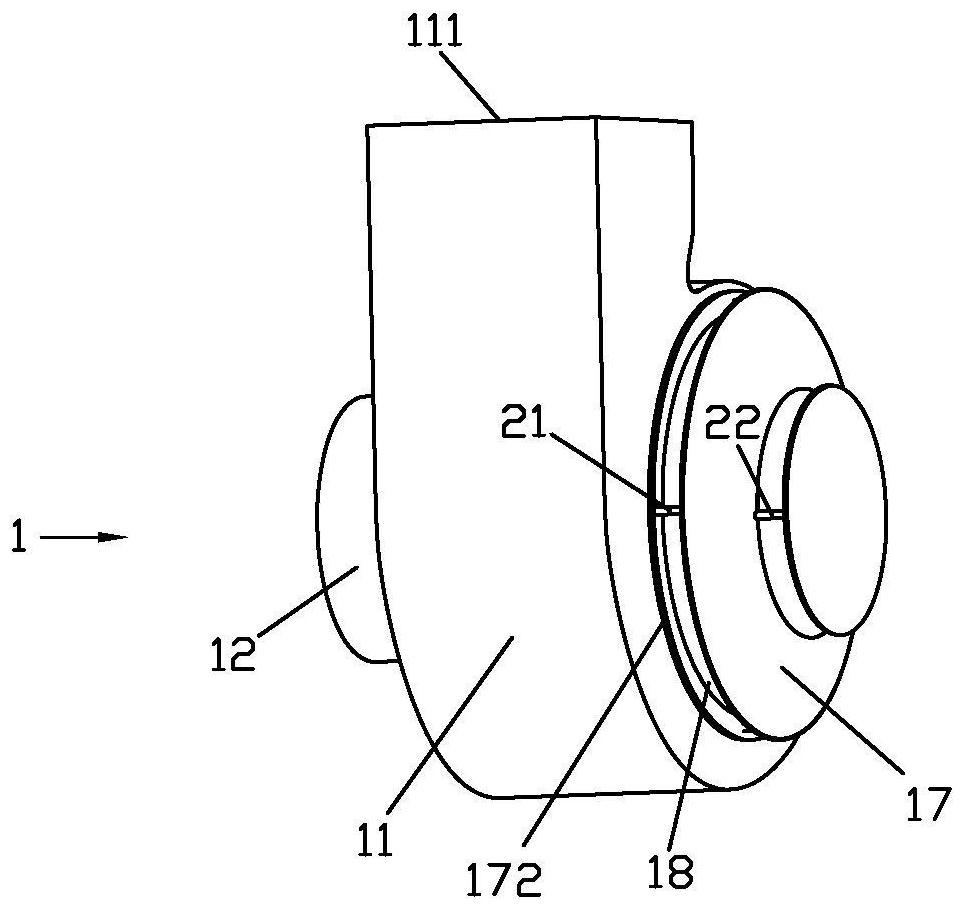

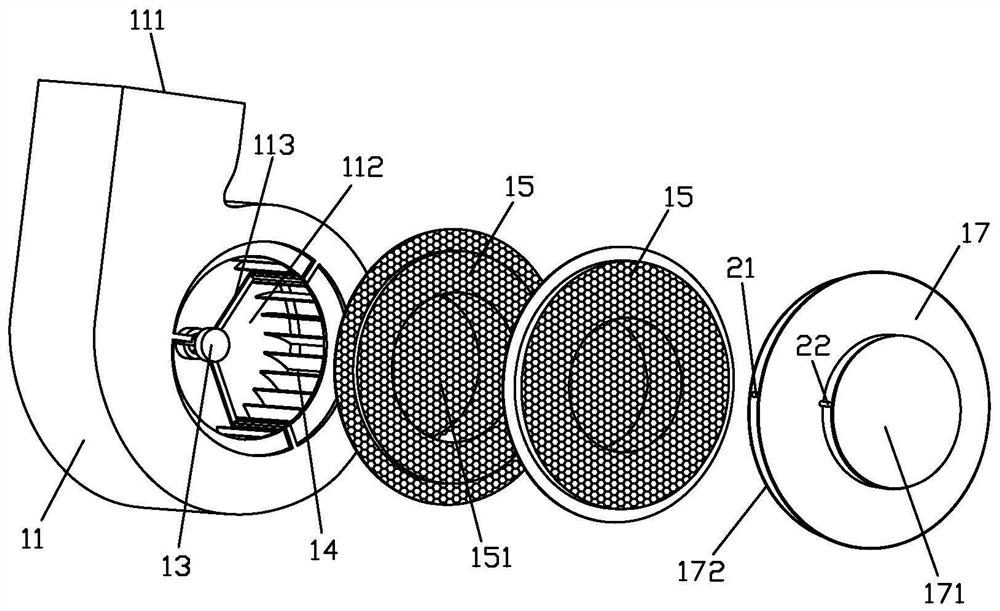

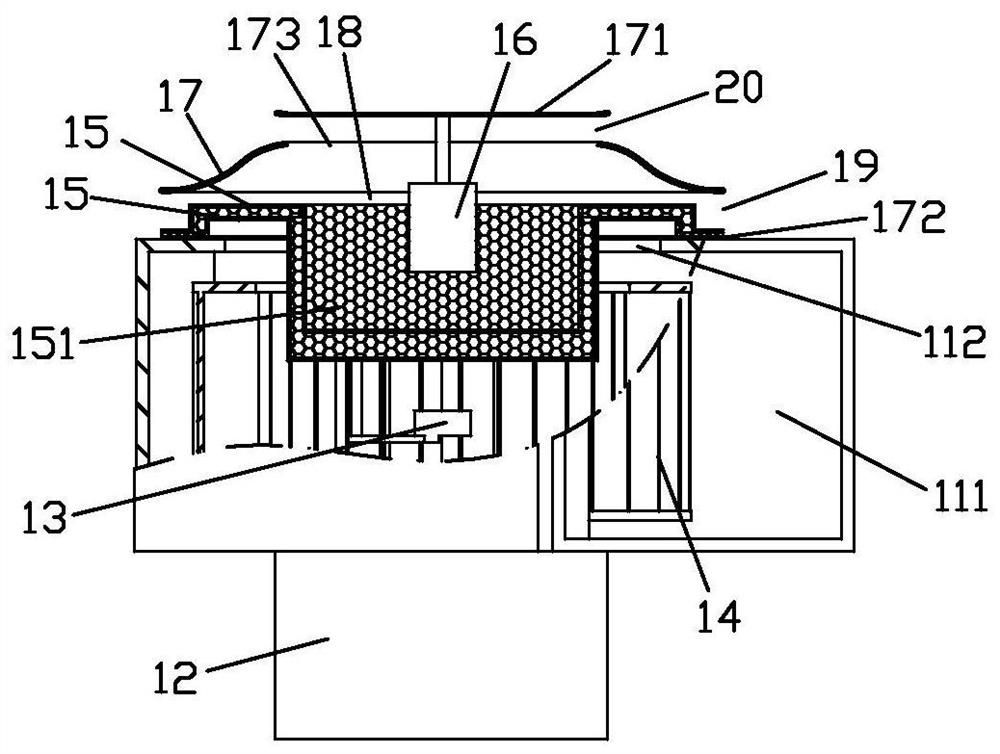

[0034] Such as Figure 1 to Figure 3 Shown is the self-sterilizing fan 1 of Embodiment 1, which is a centrifugal fan, which includes a casing 11 , a motor 12 and an impeller 14 .

[0035] The casing 11 is provided with an air inlet 112 and an air outlet 111, the air inlet 112 is located on the front of the casing 11, the air outlet 111 is located at the upper end of the casing 11, the impeller 14 is installed in the casing 11, and the motor 12 is installed in the casing 11 On the back side, the output shaft of the motor 12 is connected with the impeller 14. In order to enable the fan itself to have a disinfection function, a disinfection component is integrated at the air inlet of the casing in this embodiment.

[0036] Wherein, the disinfection assembly includes a shroud 17, an ultraviolet lamp and two layers of photocatalyst nets 15, and the number of layers of the photocatalyst net 15 and the quantity of ultraviolet lamps can be determined according to disinfection require...

Embodiment 2

[0049] The difference between the fan with disinfection function of Embodiment 2 and Embodiment 1 is that a disinfection device is added in the form of a branch circuit. This disinfection device is a combined labyrinth gas-liquid disinfection device disclosed in Chinese Patent No. 200610035126.8. .

[0050] Such as Figure 5 As shown, the disinfection and sterilization device is installed in the fan housing 2, positioned above the self-disinfection fan 1, and the fan housing 2 is provided with a branch air inlet 24 corresponding to the air inlet of the disinfection and sterilization device, and the air outlet of the disinfection and sterilization device The end is provided with an air duct 4, and the air duct extends into the first side air outlet 19, thereby connecting the air outlet end of the disinfection and sterilization device with the air inlet space 18. The inlet of the combined labyrinth gas-liquid disinfection and sterilization device 3 is the air inlet end, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com