Porous media heat exchange device and system

A technology of porous media and heat exchange devices, applied in the field of hydrogenation or dehydrogenation, which can solve the problems of low heat exchange efficiency and achieve the effect of increasing heat exchange efficiency and convection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The present invention provides a solution for a porous medium heat exchange device and system, specifically as follows:

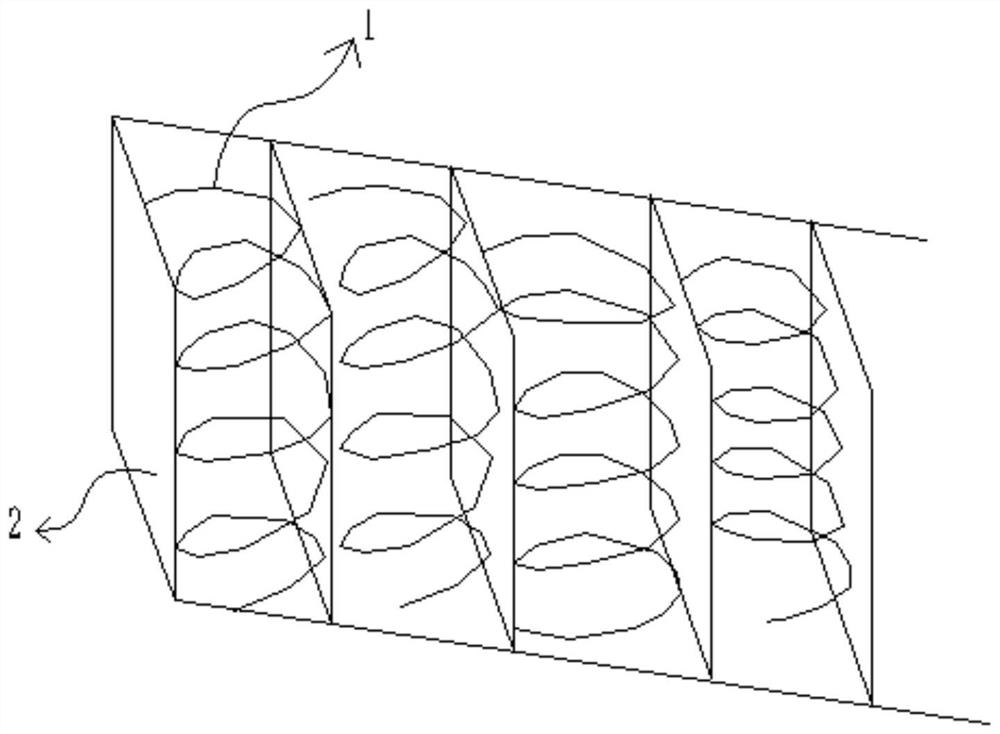

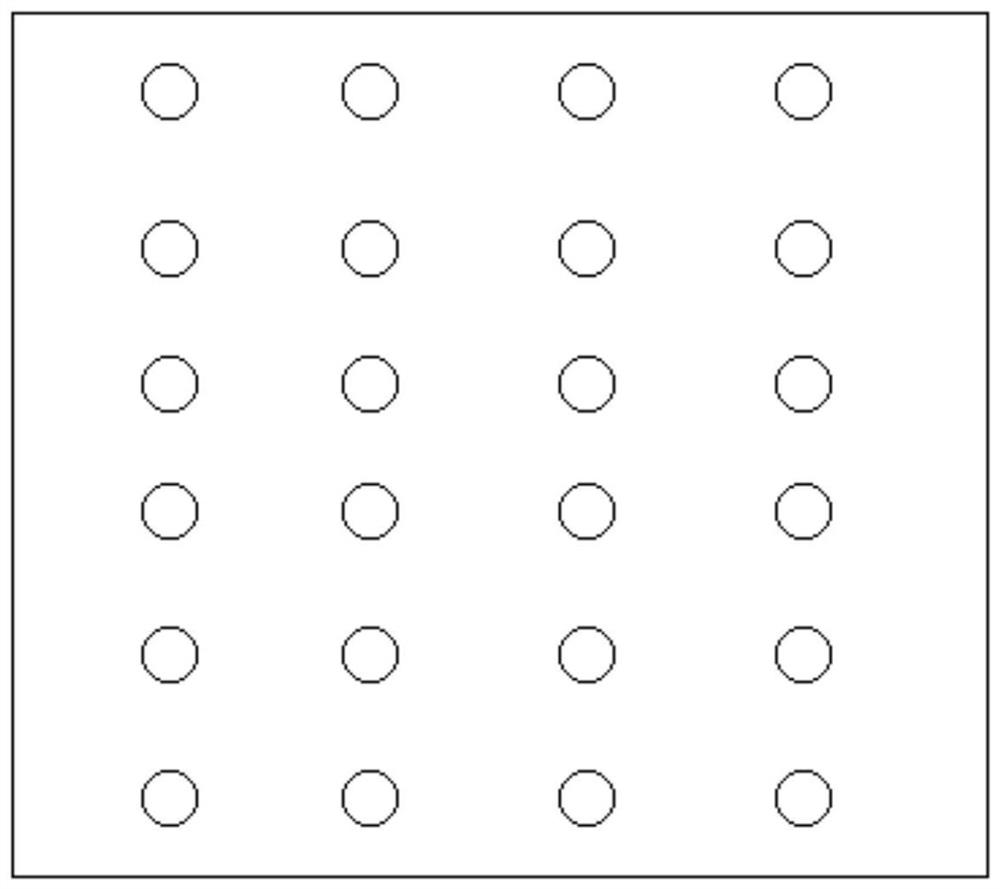

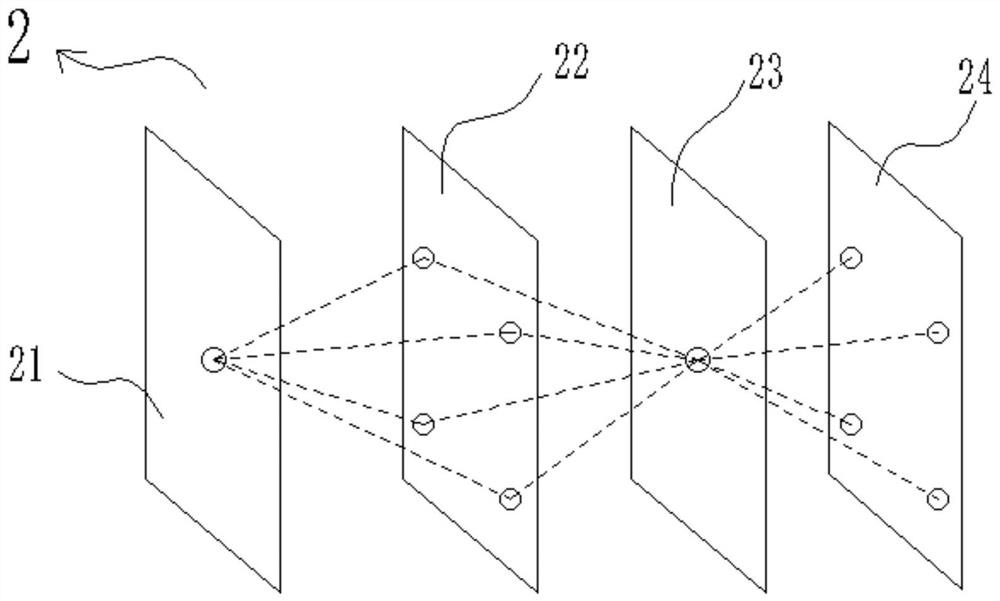

[0034] A porous medium heat exchange device 34, such as Figure 1-5 As shown, it includes: a plurality of sheet-shaped heat pipes arranged at intervals, and a porous hydrogen storage alloy 1 is arranged between every two adjacent sheet-shaped heat pipes; each sheet-shaped heat pipe is provided with flow holes; adjacent sheet-shaped heat pipes The flow holes of the sheet heat pipe are arranged in a staggered manner, and the flow holes of the previous sheet heat pipe correspond to the centers of the plurality of flow holes of the latter sheet heat pipe, so reciprocating settings, such as Figure 4 As shown, the center is a through hole (a', b', c' on the second sheet 22 are all through holes at the central position, corresponding to the flow holes a, b, c on the first sheet 21 respectively), each The flow hole of the sheet heat pipe corresponds to a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com