Boiler water wall ash pollution monitoring system

A monitoring system and water-cooled wall technology, applied in the field of intelligent control system of combustion equipment, can solve the problems of improper soot blowing cycle, excessive soot blowing, insufficient soot blowing of soot blowing system, etc., so as to reduce the risk of damage and reduce the thermal power of pipe wall. Even quantity, the effect that is conducive to large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

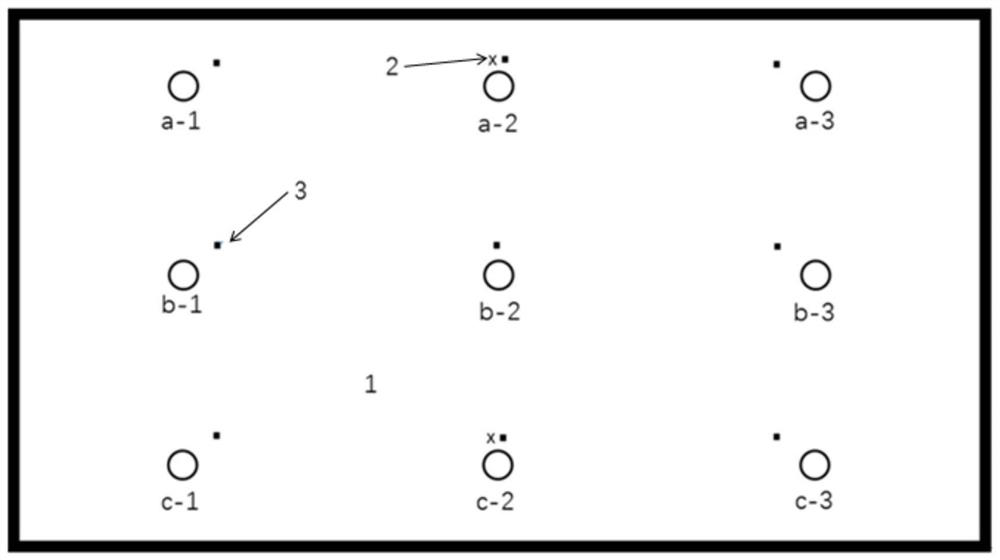

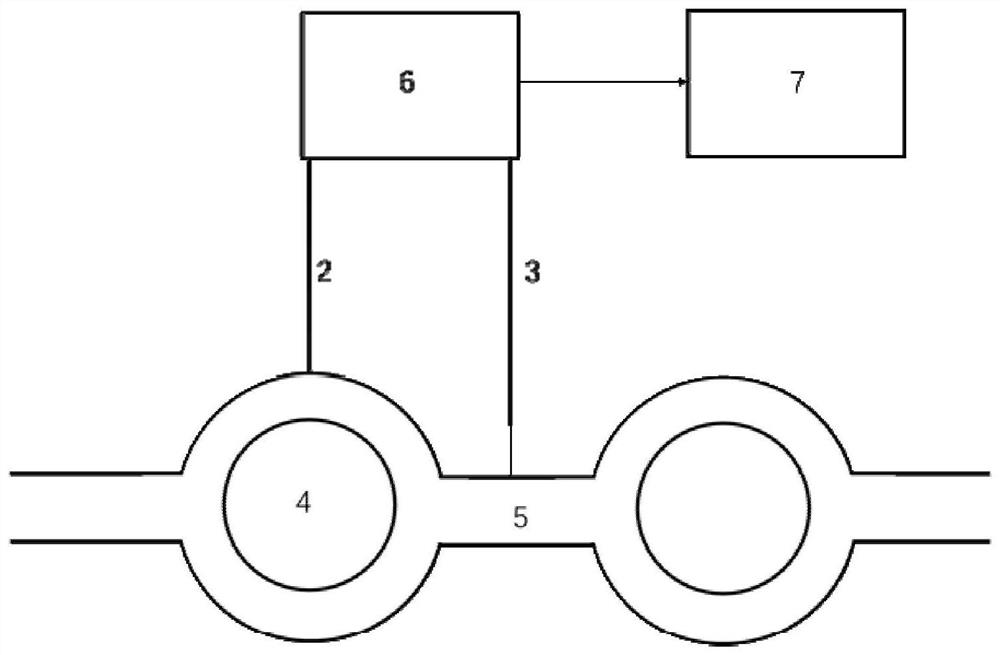

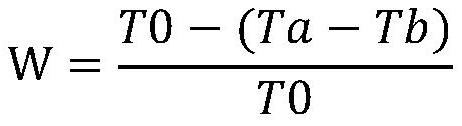

[0027] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a disclosed boiler water wall ash monitoring system including 9 sootblowers a-1-c-3 on the boiler water wall 1, 9 fin thermocouples 3, and 2 wall warmers Galvanic couple 2. Each sootblower corresponds to a fin thermocouple 3, and the fin thermocouple 3 is arranged next to the corresponding sootblower near the center line of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com