Shielding tail cover

A technology of tail cover and tail clamp, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of shielding performance impact, cable damage, cable damage, etc., to improve shielding efficiency, buffer alternating stress, and good shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention is used to connect the shielding layer of the cable itself:

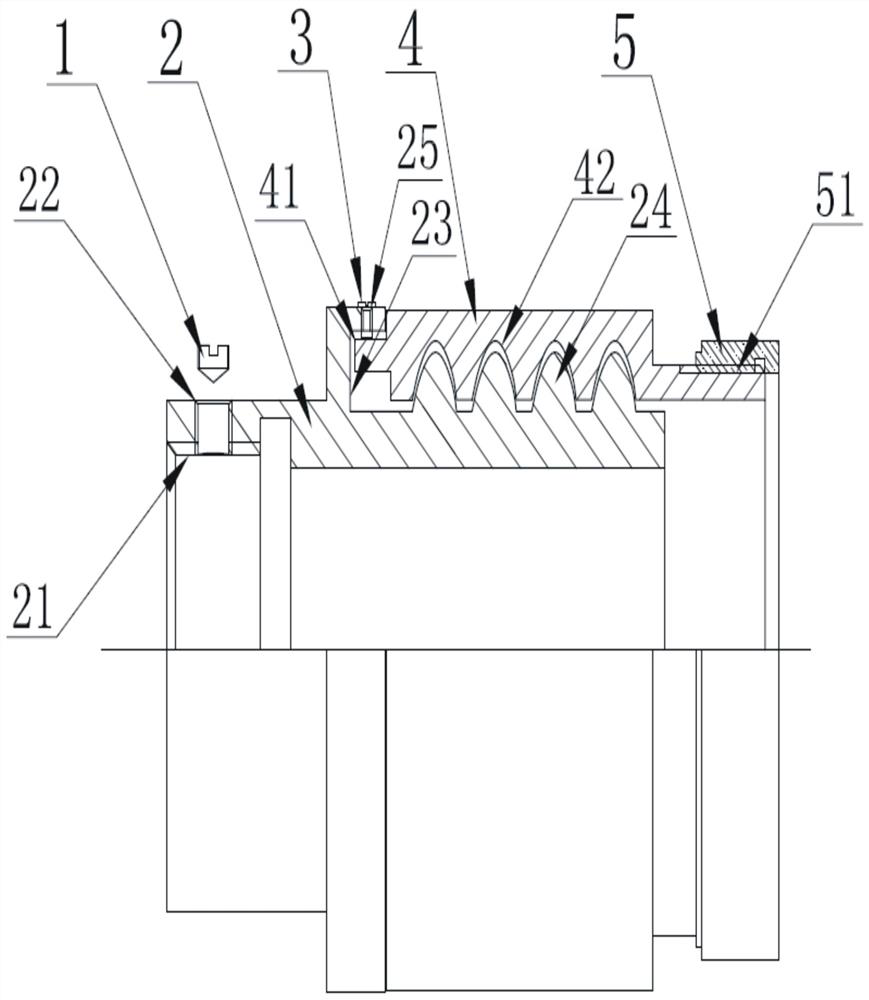

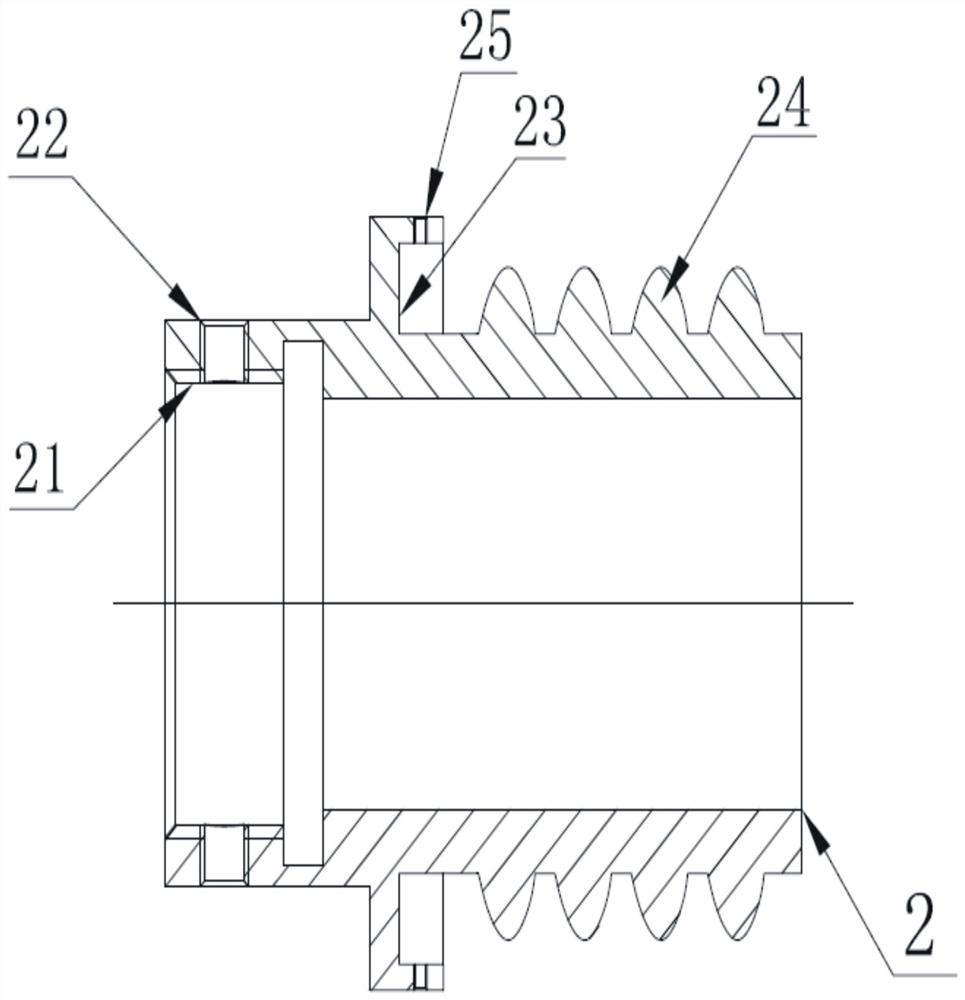

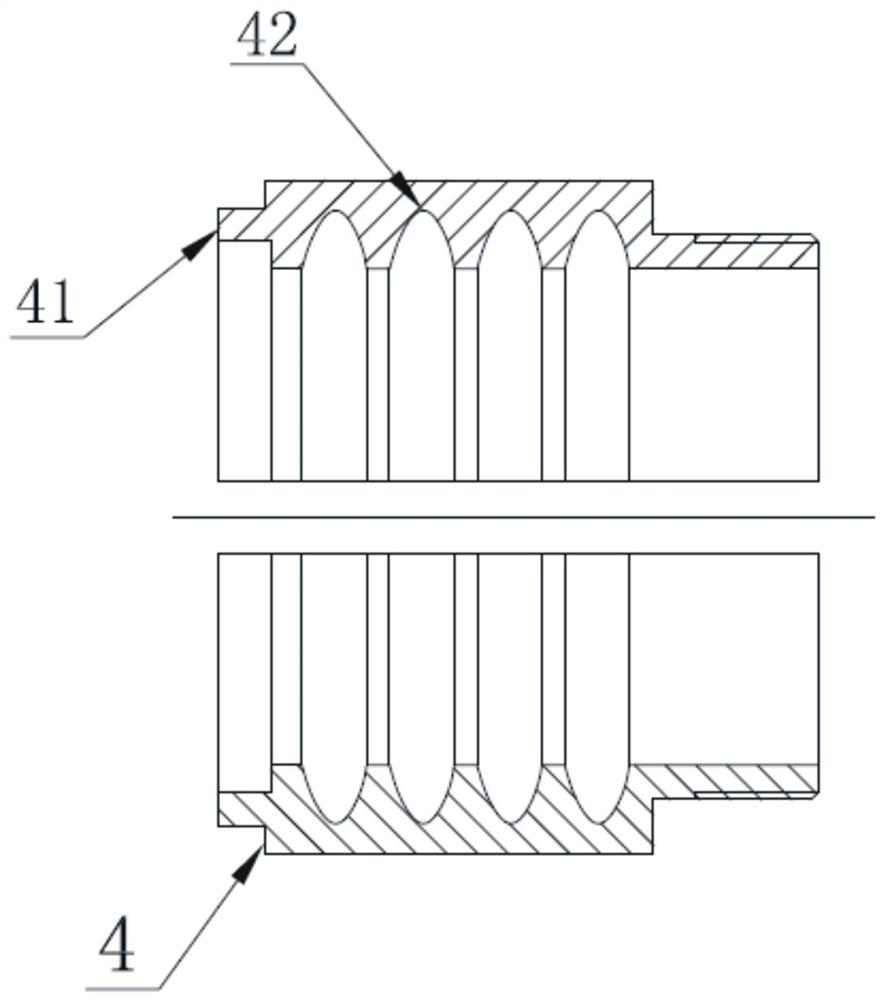

[0033] refer to figure 1 , Figure 5 , for the connection of a single cable with its own shielding layer, the core, shielding layer and insulation layer of the cable are stripped; the screw sleeve 5 and the tail cover shell 2 are inserted into the cable in sequence, and the core of the cable and the connector Connect the terminal of the terminal, put the shielding layer of the cable on the surface of the corrugated surface 24 protruding from the tail cover shell 2, fasten the tail clip 4 on the tail cover shell 2, and install the boss 41 of the tail clip 4 on the tail cover shell 2. In the notch 23 of the cover shell 2, as the concave corrugations 42 on the tail clip 4 engage with the convex corrugations 24 on the tail cover shell 2, the shielding layer is squeezed between the tail cover shell 2 and the tail clip 4 Between them, the internal thread 51 of the threaded sleeve 5 is engage...

Embodiment 2

[0036] The present invention is used to connect the additional shielding layer of the cable:

[0037] refer to figure 1 , Figure 6 , for multiple cables, no matter whether the cables have their own shielding layer or not, the multiple cables need to be uniformly shielded externally. At this time, the additional shielding layer 6 of the sleeve shape is used; one end of the additional shielding layer 6 is connected to the present invention, through the present invention The invention is connected with a connector, and the other end is connected with the outer surfaces of multiple cables by binding them with clamps.

[0038] When connecting, first strip the wire cores, shielding layers and insulating layers of multiple cables; put the additional shielding layer 6, screw sleeve 5 and tail cover shell 2 into multiple cables in sequence, and connect the cores of multiple cables with each other in sequence. Connect the connecting terminal of the connector, put the additional shiel...

Embodiment 3

[0041] To place a cable and additional shielding between two pieces of the invention:

[0042] refer to figure 1 , Figure 7 , one end of the additional shielding layer 6 is connected to the present invention, connected to a connector through the present invention, and the other end is connected to another connector through the present invention; the additional shielding layer 6 is arranged between the two present inventions, and the cable The received external force is transmitted to the two tail cover shells 2 through the shielding layer, and then respectively transmitted to the two connectors by the two tail cover shells 2, so as to slow down and eliminate the stress on the connection point between the cable and the terminal.

[0043] refer tofigure 1 The stepped hole 21 of the tail cover housing 2 of the present invention is adapted to the end of the connector, which can be used for circular or rectangular connectors to realize the processing of a single cable or multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com