Wind turbine and its fan shaft

A technology for wind turbines and main shafts, which is applied in the direction of wind power generators, wind power generation, engines, etc., and can solve the problems of increased size, low production efficiency and high production cost of wind turbine main shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

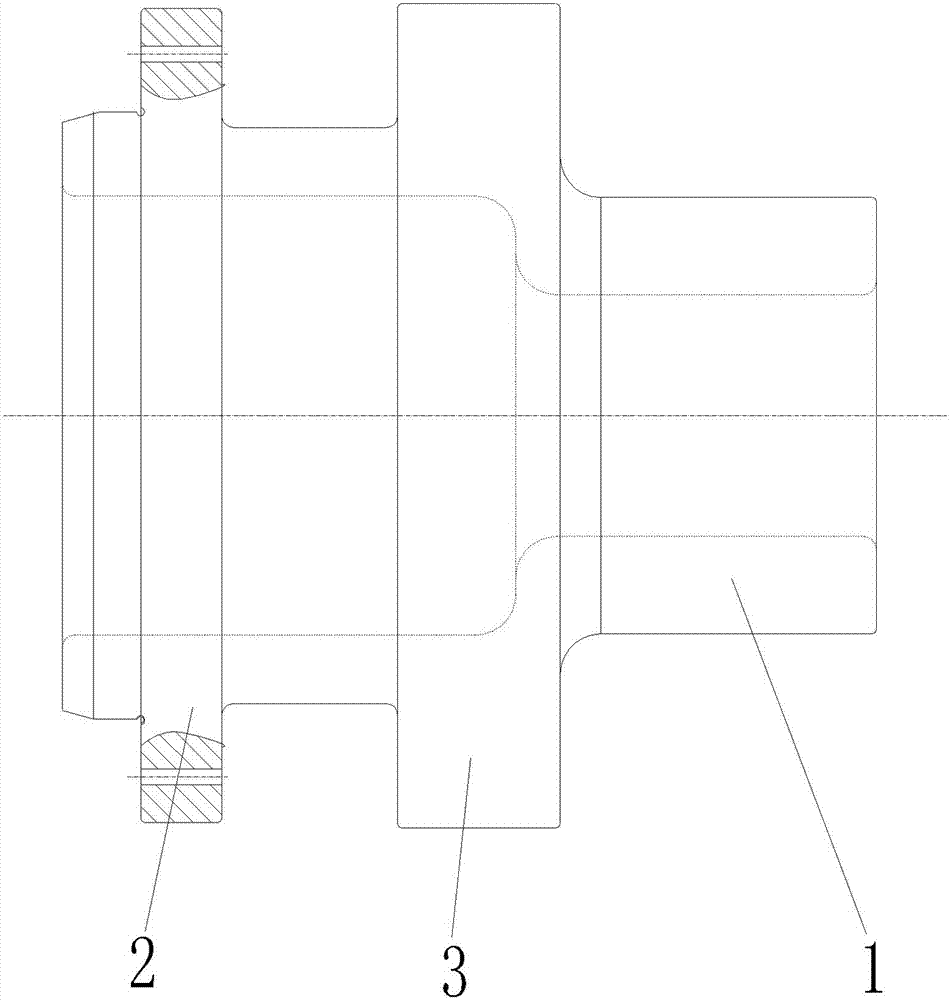

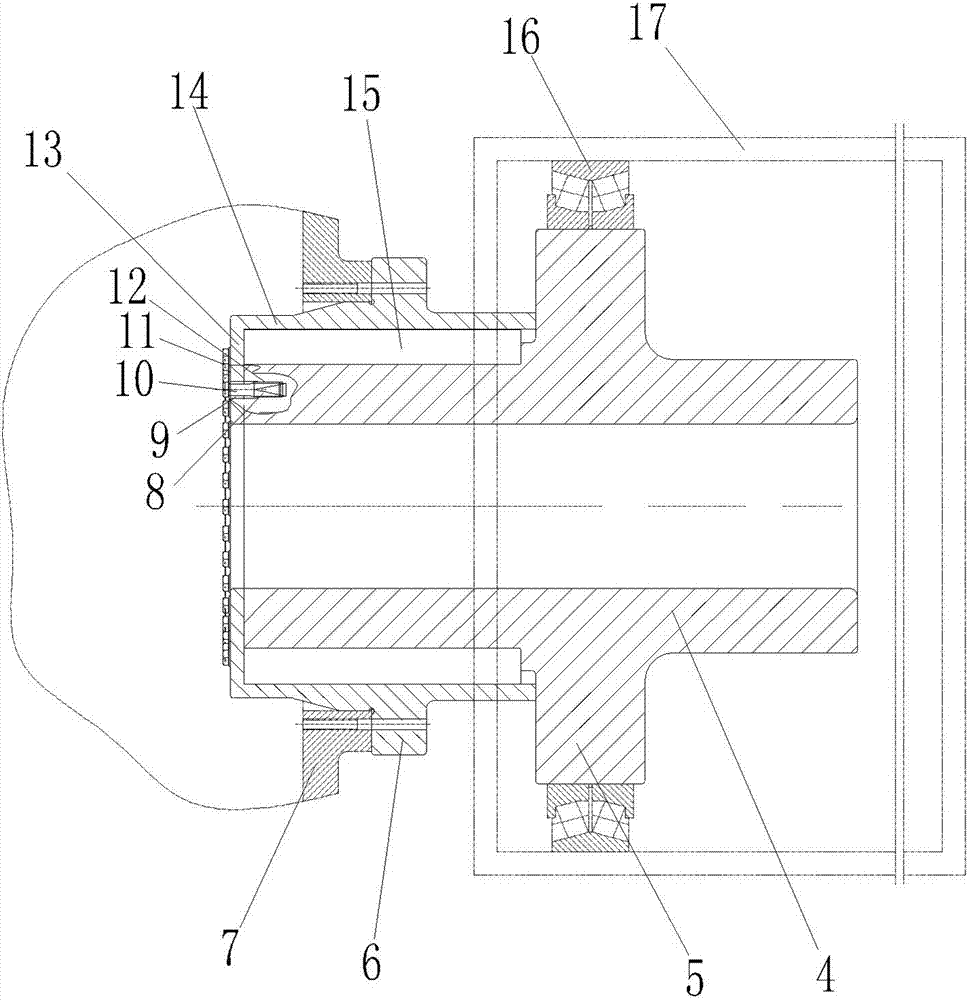

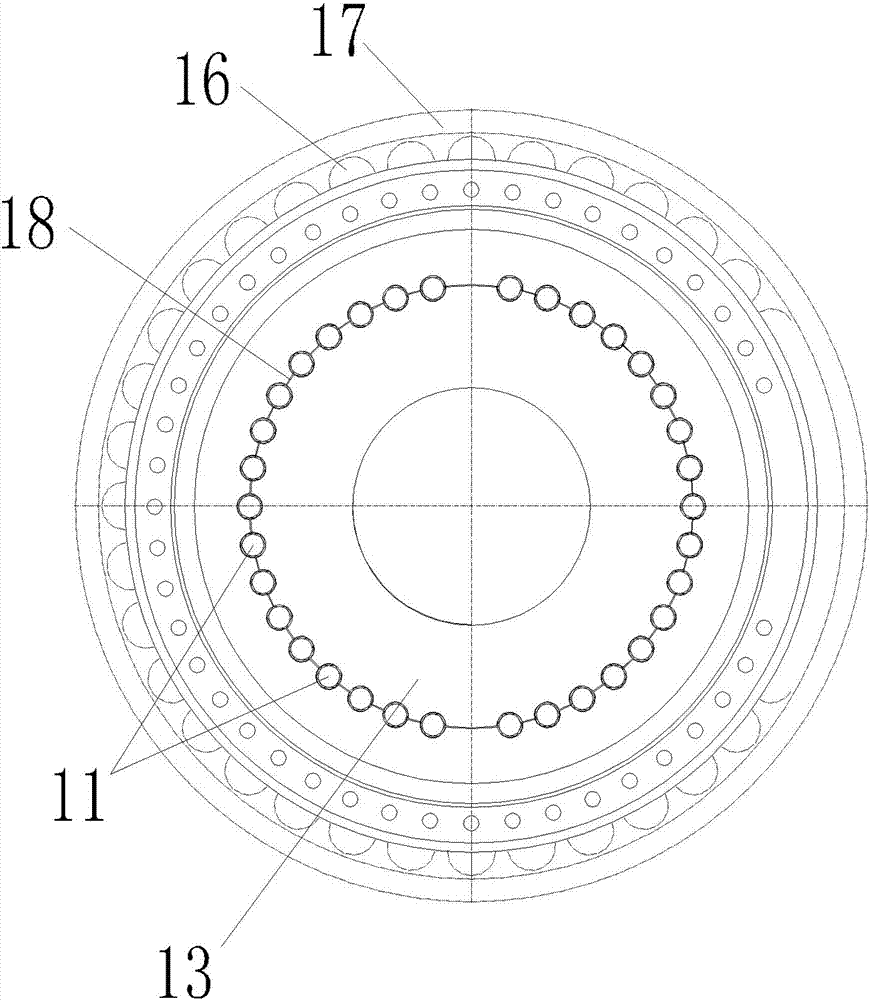

[0021] Examples of wind turbines are Figure 2~3 Shown: including the fan hub 7, the gearbox 17 and the fan main shaft connected between the fan hub 7 and the gearbox 17, the fan main shaft includes the main shaft body and the connecting flange 6 and the bearing installation ring platform 5 arranged at intervals before and after, connected The flange 6 is placed outside the casing of the gearbox 17, the connecting flange 6 is fixedly connected with the fan hub 7, the bearing mounting ring 5 is placed in the casing of the gearbox, and the bearing mounting ring and the inner wall of the casing of the gearbox A main shaft bearing 16 is provided, the input end of the gearbox is connected with the rear main body, and the output end of the gearbox is connected with the generator. The main shaft body includes a front body part and a rear body part 4 which are arranged separately and mated together. The front and rear body parts are fixedly connected by a fixed structure, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com