Self-cleaning heat dissipation type monitoring camera

A monitoring camera and heat dissipation technology, applied in the field of monitoring equipment, can solve the problems of easy adhesion of dust to the lens of the service life monitoring camera, poor heat dissipation, etc., and achieve the effect of ensuring cleanliness, fast gas flow rate, and improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

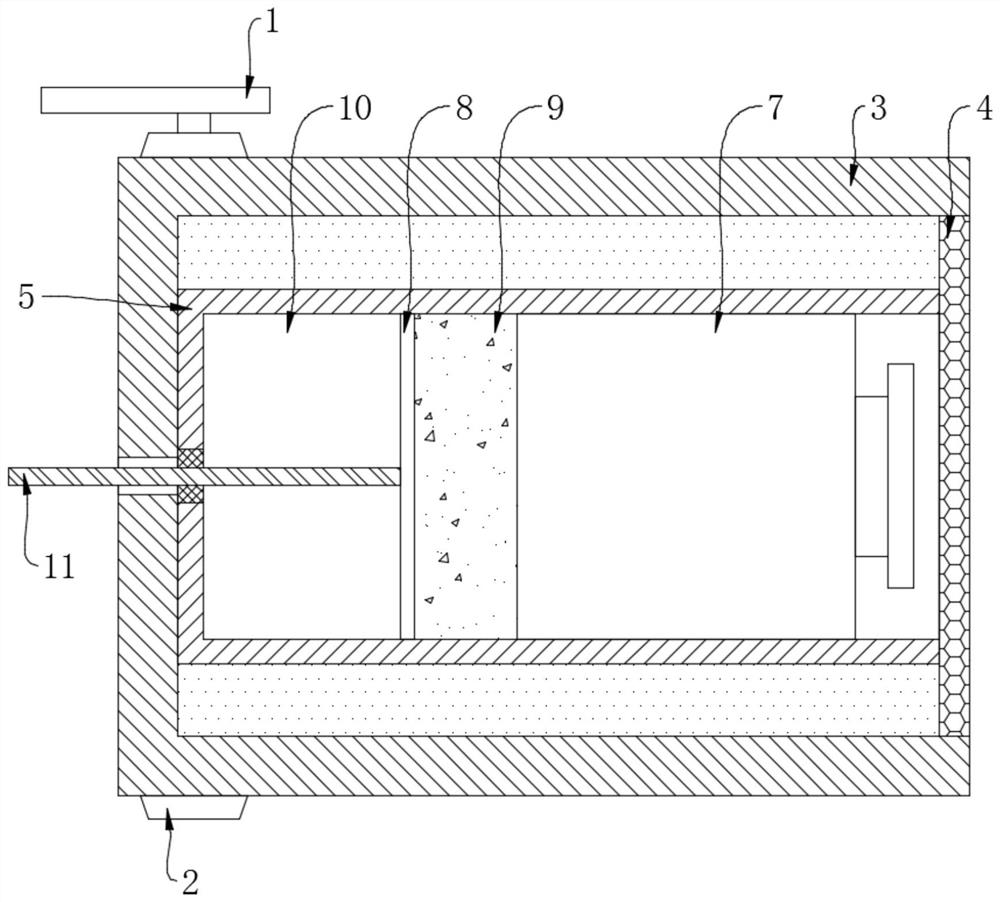

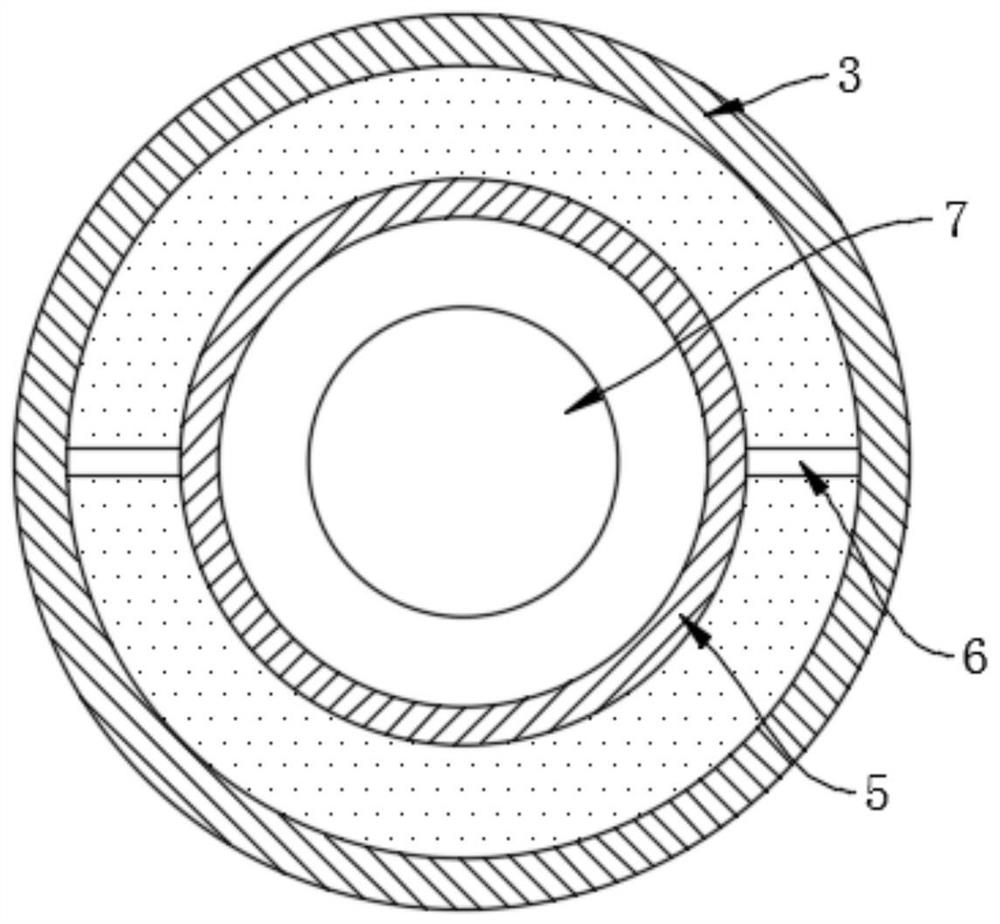

[0022] refer to Figure 1-2 , a self-cleaning and heat-dissipating monitoring camera, including a mounting base 1 and a camera body 7, a fixing ring 2 is fixed on the mounting base 1, a rotating drum 3 is fixedly installed in the fixing ring 2, and the opening of the rotating drum 3 is detachably sealed The light-transmitting plate 4 is connected, and the installation cylinder 5 is installed coaxially rotating inside the drum 3, and the opening of the installation cylinder 5 is sealed and slidingly connected with the side wall of the light-transmitting plate 4, and the outer wall of the installation cylinder 5 is symmetrically and fixedly connected with two partitions 6. The end of each partition 6 away from the corresponding installation cylinder 5 is sealed and slidably connected to the inner wall of the drum 3 , and multiple partitions 6 form a sealed space composed of the inner wall of the drum 3 , the outer wall of the installation cylinder 5 and the light-transmitting pla...

Embodiment 2

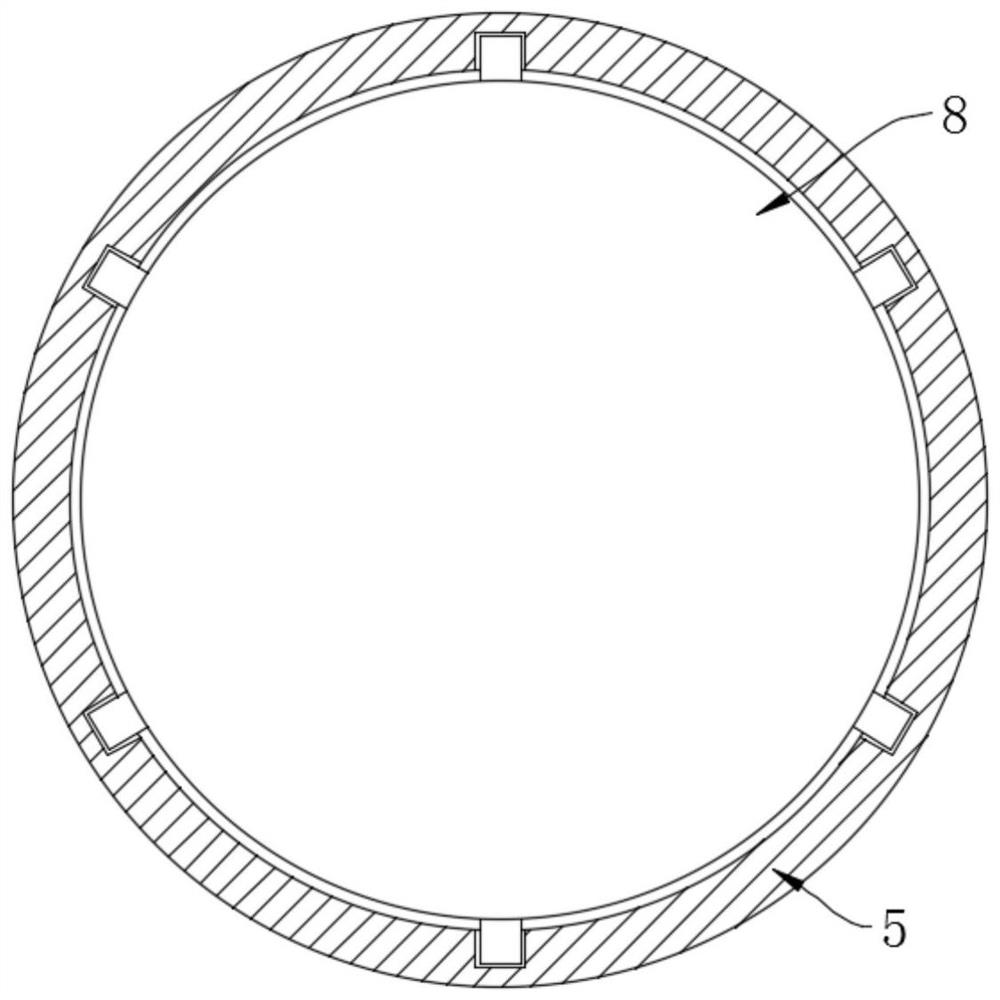

[0027] refer to Figure 4-5 The difference between this embodiment and Embodiment 1 is that: the threaded rod 11 is covered with an annular air bag 12, and the annular air bag 12 is located in the placement area 10, and the left and right side walls of the annular air bag 12 are respectively fixedly connected to the installation tube On the inner wall of 5 and the side wall of piston plate 8, the installation tube 5 is provided with the one-way exhaust pipe 13 that communicates with the annular airbag 12, and the other end opening of the one-way exhaust pipe 13 is sealed with the side wall of the light-transmitting plate 4 Slidingly connected, the light-transmitting plate 4 is provided with an air duct 14 corresponding to the one-way exhaust pipe 13, and the other end of the air duct 14 points to the center of the right side wall of the light-transmitting plate 4, and the annular airbag 12 is provided with an air duct communicating with the outside world. The one-way air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com