Embryonated egg post hatching device for poultry vaccine production

A technology for vaccine production and embryonic eggs, applied in poultry incubators, applications, poultry industry, etc., can solve problems such as high cost, impact on chicken embryo development, egg damage, etc., achieve low cost, improve culture quality and efficiency, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

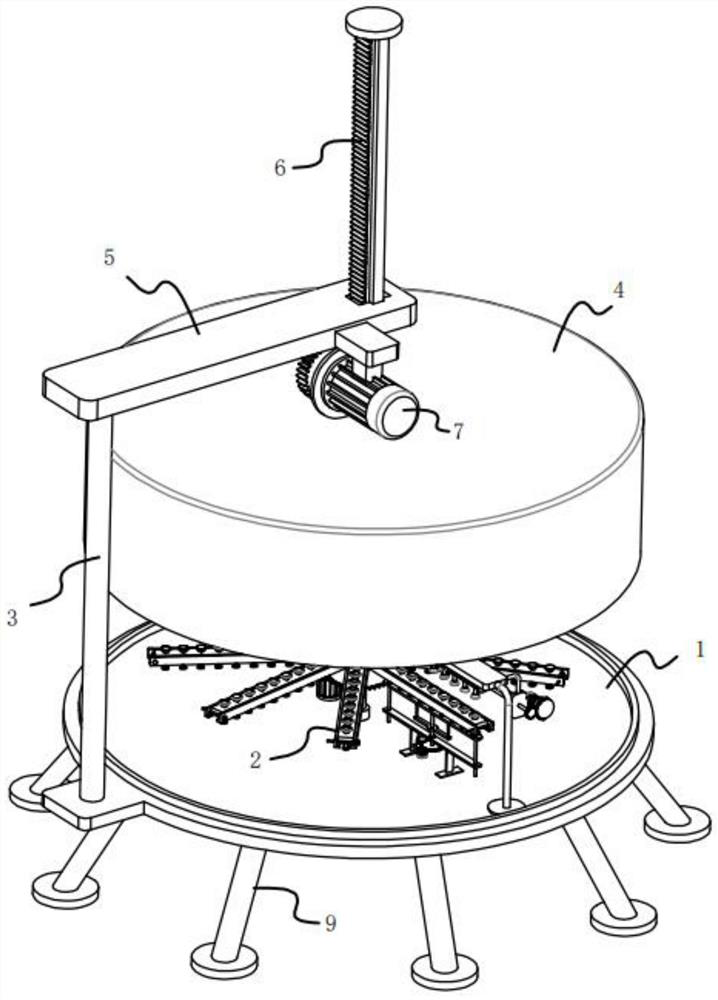

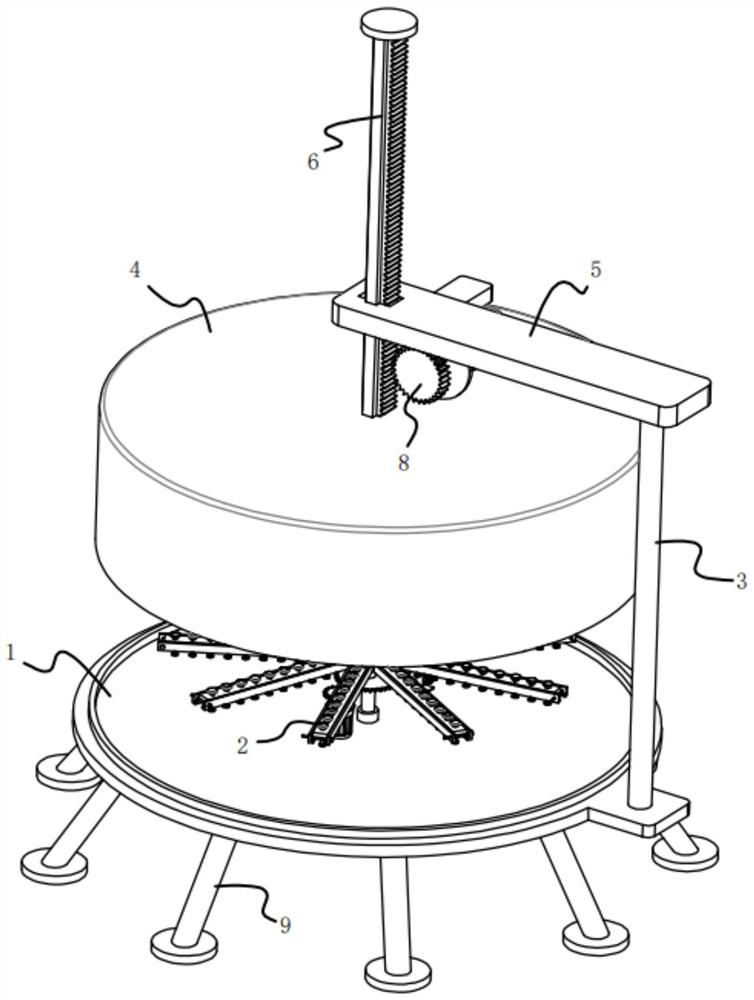

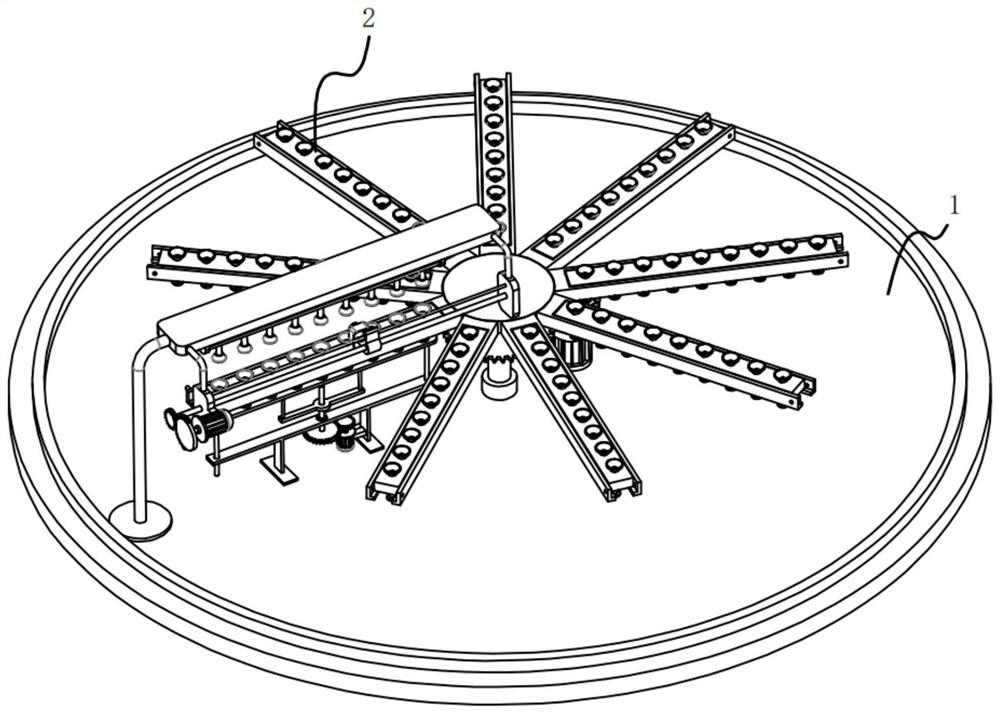

[0027] refer to Figure 1-10, a post-egg hatching device for poultry vaccine production, comprising a hatching tray 1, the upper surface of the hatching tray 1 is fixedly provided with a hatching assembly 2, the upper surface of the hatching tray 1 is also fixedly installed with a support column 3, and the top of the support column 3 is fixedly installed There is a top plate 5, the upper surface of the top plate 5 is provided with a rack 6, the bottom end of the rack 6 is fixedly installed with an incubation cover 4 covering the hatching assembly 2, and the lower surface of the top plate 5 is fixedly installed with the first motor corresponding to the rack 6 7. A first gear 8 meshing with the rack 6 is fixedly installed on the end of the output shaft of the first motor 7 , and a number of support legs 9 evenly distributed are fixedly installed on the lower surface of the hatching tray 1 . When hatching, the hatching cover 4 covers the hatching assembly 2 on the hatching tray 1...

Embodiment 2

[0033] refer to Figure 4-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the camera mechanism includes a second threaded rod 34, a movable sleeve 35, a guide rod 36, a fixed seat 37, an industrial camera 38, and the first horizontal plate 28 Any one side is fixedly installed with the first side plate 29 that is arranged correspondingly, and the second threaded rod 34 that is arranged parallel to the second horizontal plate 30 is rotatably installed between two first side plates 29, and on the second threaded rod 34 The threaded sleeve is provided with a movable sleeve 35, and the movable sleeve 35 is provided with a guide rod 36 parallel to the second threaded rod 34. A fixed seat 37 is fixedly installed on the inner side of the cover 35, and an industrial camera 38 disposed toward the second horizontal plate 30 is fixedly installed on the fixed seat 37, and the second threaded rod 34 is transmission-connected with a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com