Yarn heating and humidifying dust cover

A dust cover and yarn technology, applied in protective clothing, clothing, clothing, etc., can solve the problems of large air flow, low adjustment accuracy, and high energy consumption, so as to improve air flow speed, avoid high humidity, The effect of improving the volatilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

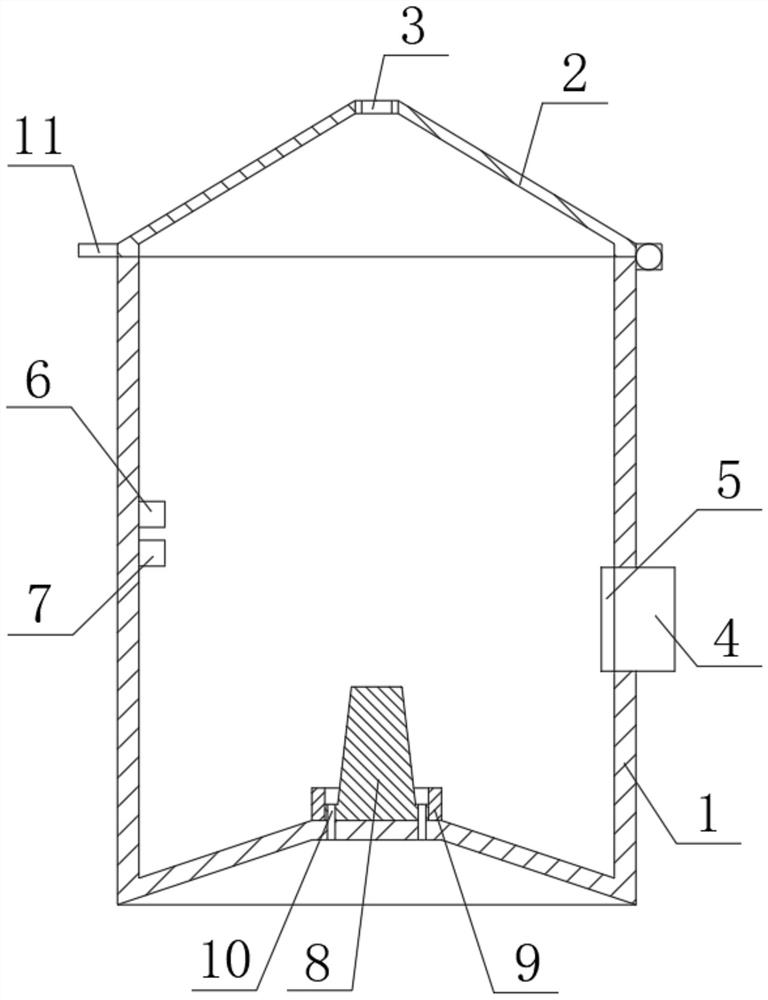

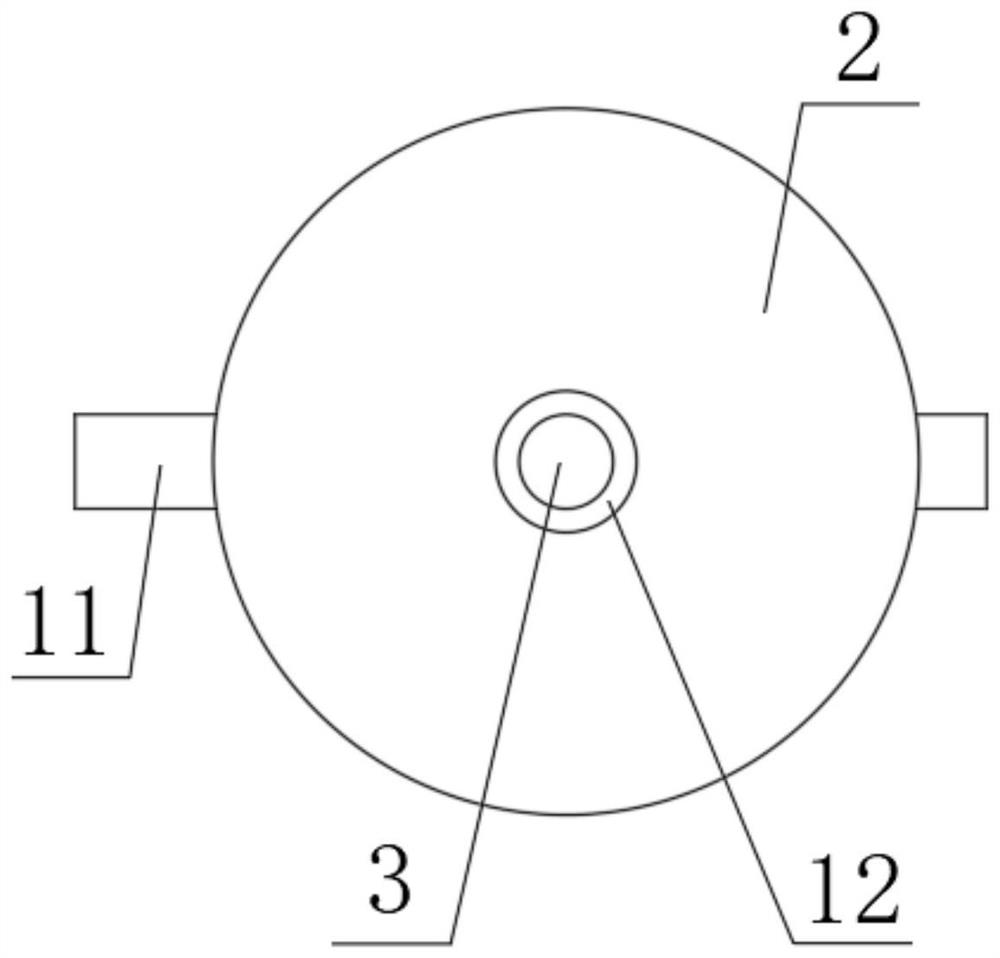

[0016] Example. A kind of yarn heating and humidifying dustproof cover, constituted as follows figure 1 and 2 As shown, it includes a placement tube 1, the top cover of the placement tube 1 is provided with a top cover 2, and the top cover 2 is provided with an outlet hole 3; a fan 4 is connected to the side wall of the placement tube 1, and a heating fan 4 is connected to the fan 4. device 5; the placement cylinder 1 is connected with a temperature sensor 6 and a humidity sensor 7.

[0017] The middle part of the bottom end of the placement cylinder 1 is arranged in an upwardly convex shape; the highest position of the bottom end of the placement cylinder 1 is provided with an upwardly protruding placement platform 8; the bottom end of the placement cylinder 1 corresponds to the position of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com