Flat sheet membrane device capable of forming water outlet and circulation channels after being spliced

A flow channel, flat membrane technology, applied in biological treatment devices, membranes, membrane technology and other directions, can solve the problems of time-consuming and laborious, easy aging of hoses, inconvenient plugging, etc. The effect of water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

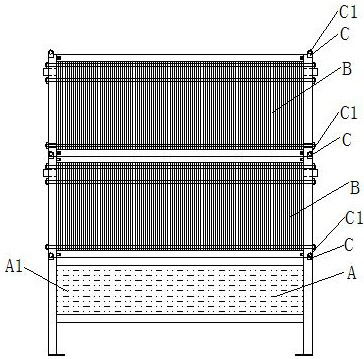

[0033] Embodiment 1: as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10, a flat membrane device that can form water outlet and circulation channels after splicing, including the aeration assembly A at the bottom and several stacked above the aeration assembly The flat-plate membrane module B, the aeration module A includes a square-shaped aeration frame A1 with top and bottom openings and an aeration tube located in the aeration frame A1, the top of the aeration frame A1 is provided with a number of limiting plates C, and the flat membrane Component B is limited by the limit plate C;

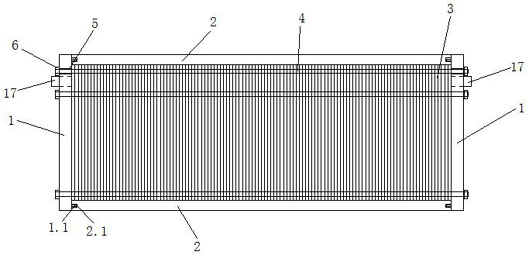

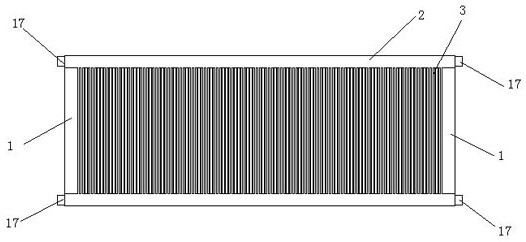

[0034]The flat membrane module includes two side plates 1 and a number of limit strips 2 connecting the two side plates 1. The side plates 1 and the limit bars 2 are inserted through concave-convex structures. The plate 1 is provided with a convex strip 1.1 for inserting into the limit bar jack 2.1, and several flat film 3 are clamped between the two side plates 1; the two side plates 1 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com