Longitudinal polishing equipment for shaft parts

A shaft parts, longitudinal technology, applied in the field of shaft parts longitudinal polishing equipment, can solve the problems of existing working environment, high working intensity, difficult quality guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

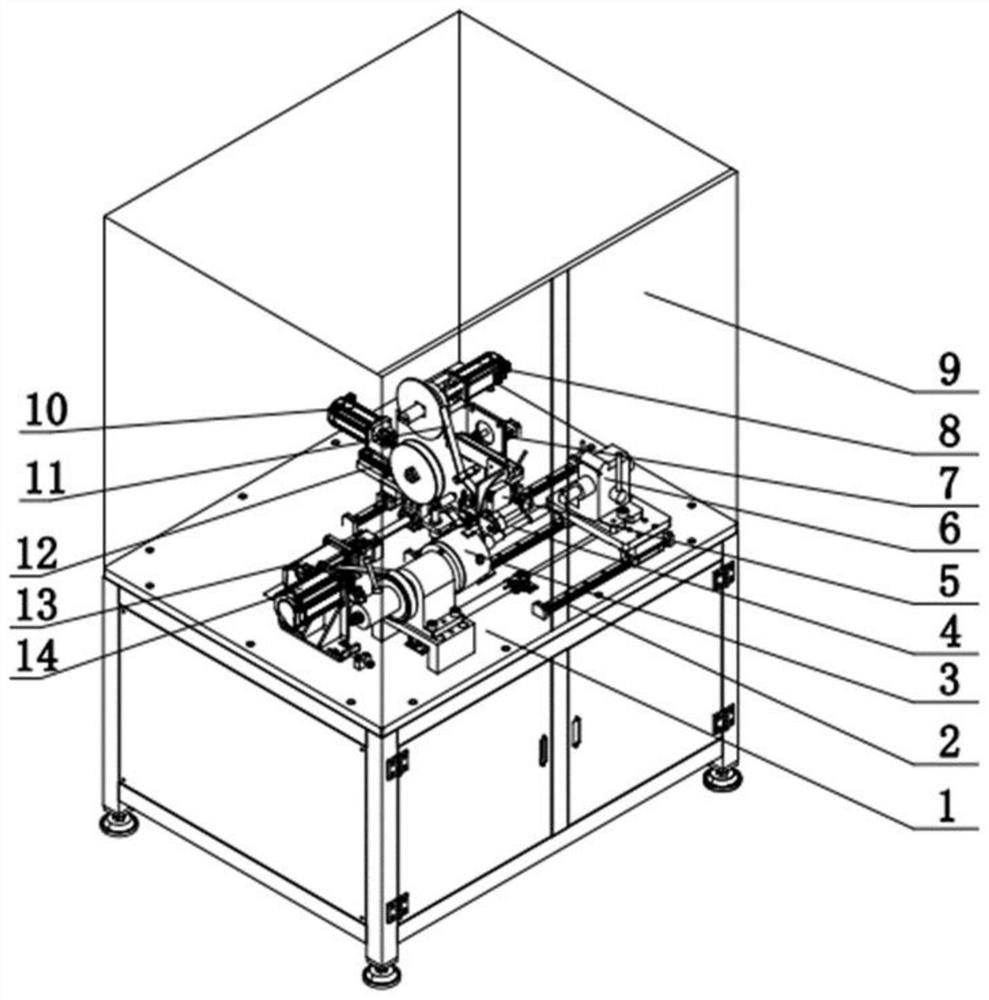

[0012] Below in conjunction with accompanying drawing, patent of the present invention is described further.

[0013] Such as figure 1 As shown, the longitudinal polishing equipment for shaft parts provided by the patent of the present invention includes: workbench (1), tailstock guide rail (2), clamping chuck (3), workpiece (4), detection device (5), tailstock (6), moving mechanism (7), polishing belt motor (8), shield (9), polishing feed motor (10), polishing belt (11), feed guide rail (12), detection device driving motor (13 ), spindle drive motor (14).

[0014] The longitudinal polishing equipment for shaft parts is characterized in that the whole equipment is self-contained, the main components are installed on the upper plane of the workbench (1) to support the whole equipment, and the upper layer of the equipment is provided with a shield (9) for processing Protect.

[0015] The longitudinal polishing equipment for shaft parts is characterized in that: the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com