Restraining abrasive particle flow polishing device of hard and brittle material complex curve part

A technology for complex curved surfaces and hard and brittle materials is applied in the field of polishing processing devices to achieve the effects of low cost, enhanced shearing effect, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

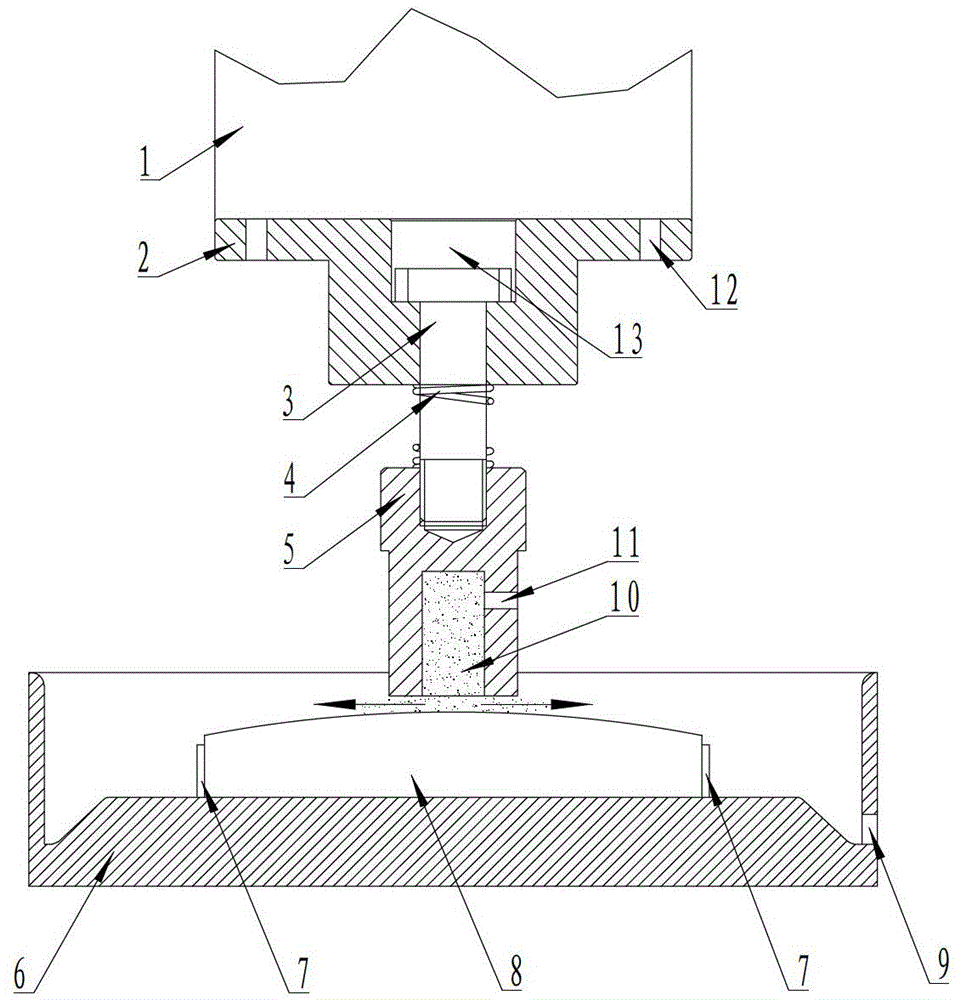

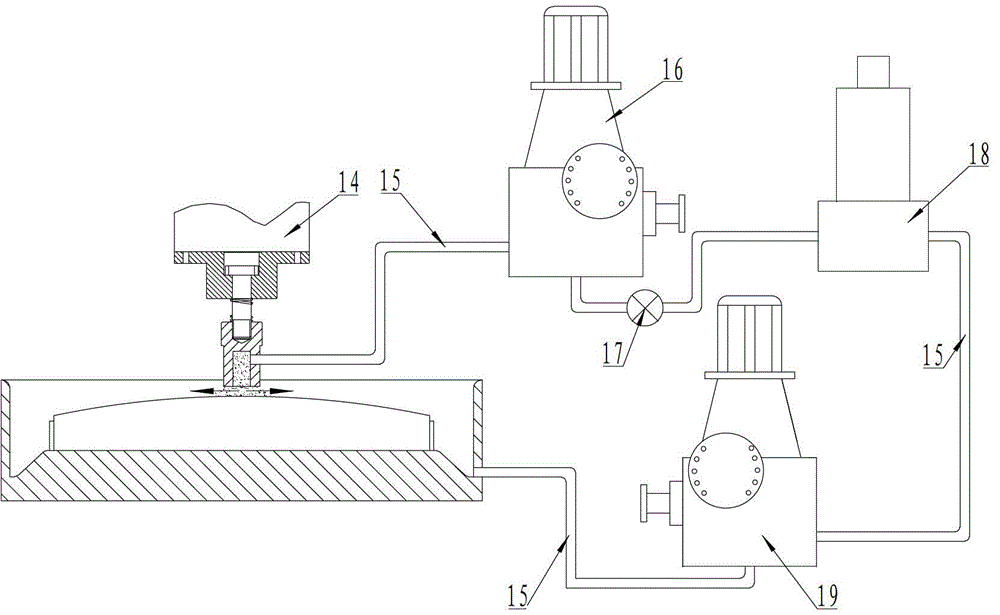

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] refer to figure 1 and figure 2 , a constrained abrasive flow polishing processing device for parts with complex curved surfaces of hard and brittle materials, comprising a polishing tool head 5, a spring 4, a set screw 3, a fixing seat 2, a recovery base 6 and a polishing robot 1, the set screw sleeve 3 is installed in the center hole of the fixing base 2, the spring 4 is sleeved outside the set screw 3, the other end of the set screw 3 is threadedly connected with the polishing tool head 5 and compresses the spring 4, and the workpiece 8 passes through the pin The column 7 is fixed on the recovery base 6, the fixed seat 2 is fixed with the polishing robot 1 by bolts, there is a counterbore with a larger diameter above the central hole of the fixed seat 2, and the top of the set screw 3 is between the polishing robot 1 There is a certain gap 13, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com