A substrate processing device for semiconductor production

A processing device and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, grinding drive devices, metal processing equipment, etc., can solve the problems of troublesome cleaning process, time-consuming and laborious, high equipment cost and high power consumption, and improve production efficiency. Improve polishing efficiency and ensure clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

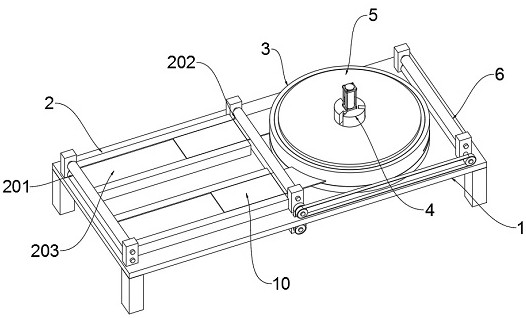

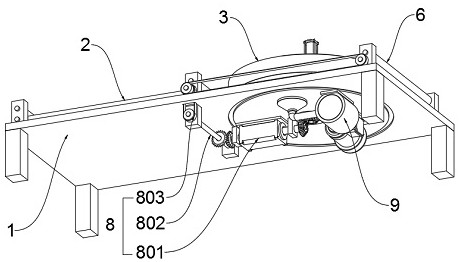

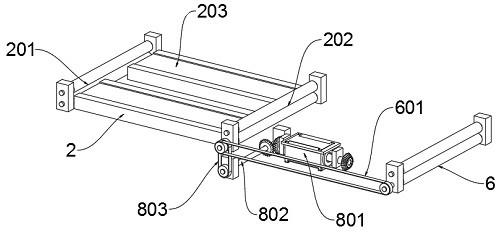

[0034] Example: Please refer to Figure 1 to Figure 8 :

[0035] The present invention proposes a substrate processing device for semiconductor production, comprising: a base 1, two drive frames 2 are arranged on the left side of the top of the base 1, and the two drive frames 2 are distributed in parallel, and the drive frame 2 is provided with Silicon wafer 10; the right side of the drive frame 2 is provided with a polishing cylinder 3, and the polishing cylinder 3 is fixedly connected to the base 1 by embedding; the middle position of the polishing cylinder 3 is provided with a rotating seat 4, and the rotating seat 4 is provided with a polishing turntable 5 , and the polishing turntable 5 is located in the polishing cylinder 3; the top right side of the base 1 is provided with a drive roller set 6; the bottom of the base 1 is provided with a driving mechanism 8, and the right side of the driving mechanism 8 is provided with a collection assembly 9.

[0036] Furthermore, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com