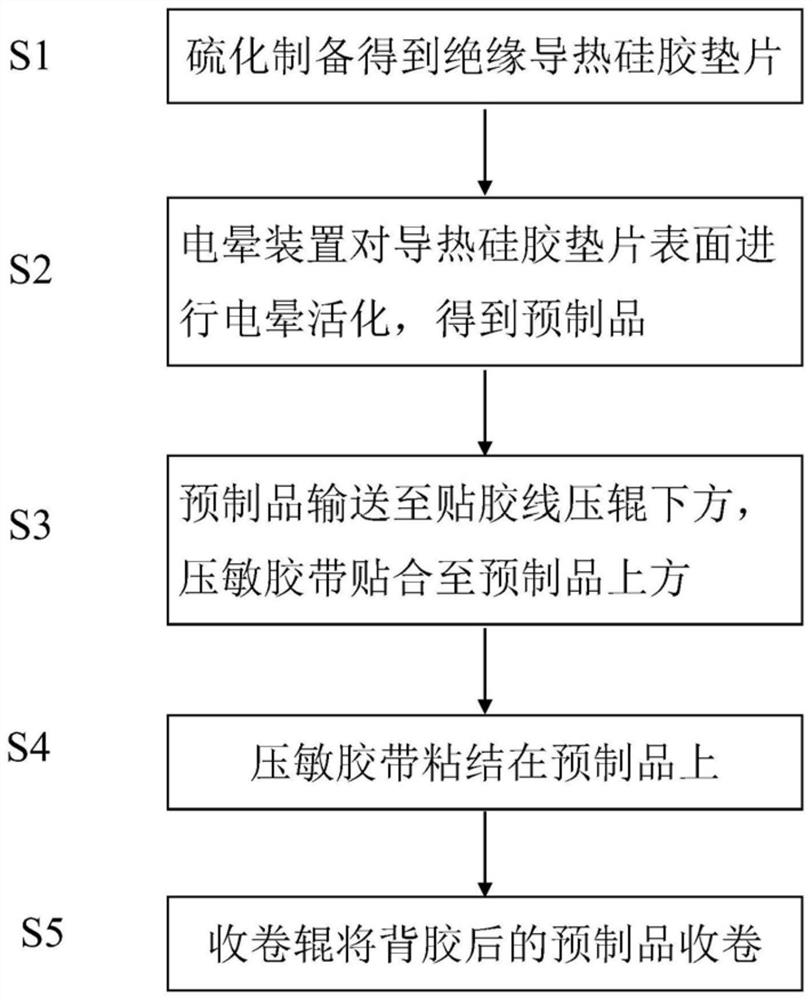

A manufacturing process of a thermally conductive silicone gasket and a back glue system used therefor

A technology of heat-conducting silica gel and manufacturing process, which is applied in the field of adhesive system, which can solve the problems of low production efficiency and labor-intensive labor, and achieve the effects of improving production efficiency, improving adhesion performance, and protecting health and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] S1. Pass the raw material of the heat-conducting silicone gasket through a calender to form a sheet-shaped gasket, and then pass through the baking line, that is, pass through the tunnel oven with the temperature set at 130°C, 140°C and 150°C in sequence, and process it in the tunnel oven for 6 minutes, vulcanization Get insulating thermal silicone gaskets;

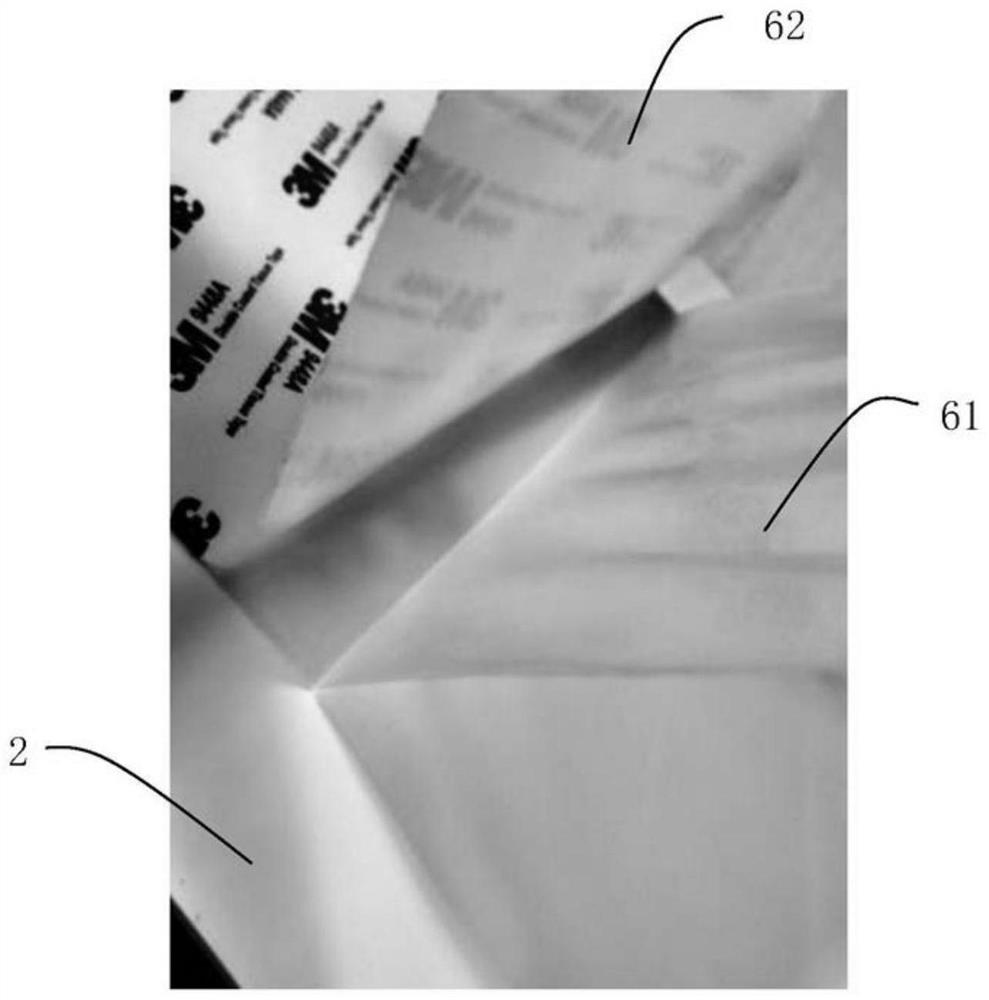

[0053] S2. Start the corona device, and the heat-conducting silica gel gasket prepared in step S1 is transported to the bottom of the electrode head in the orbital corona device by a conveyor belt. The distance between the electrode head and the treated surface of the heat-conducting silica gel gasket is 2mm, and the speed of the conveyor belt It is 1.5m / min. The orbital corona device applies high-frequency and high-voltage current to the electrode head. The working frequency of the corona device is 25KHZ, the power is 1KW, and the working voltage is 10KV. Corona discharge occurs on the electrode head. The surface ...

Embodiment 2

[0058] S1. Pass the raw material of the heat-conducting silicone gasket through a calender to form a sheet-shaped gasket, and then pass through the baking line, that is, pass through the tunnel oven with the temperature set at 130°C, 140°C and 150°C in sequence, and process it in the tunnel oven for 15 minutes, vulcanization Get insulating thermal silicone gaskets;

[0059] S2. Start the corona device, and the heat-conducting silica gel gasket prepared in step S1 is transported to the bottom of the electrode head in the orbital corona device by a conveyor belt. The distance between the electrode head and the treated surface of the heat-conducting silica gel gasket is 3mm, and the speed of the conveyor belt It is 1.6m / min. The orbital corona device applies high-frequency and high-voltage current to the electrode head. The working frequency of the corona device is 35KHZ, the power is 3KW, and the working voltage is 10KV. Corona discharge occurs on the electrode head. The surface...

Embodiment 3-4 and comparative example 1-2

[0064] Embodiments 3-4 and Comparative Examples 1-2 are different from Embodiment 1 in that the power and conveyor belt speed in Embodiment 1 are changed.

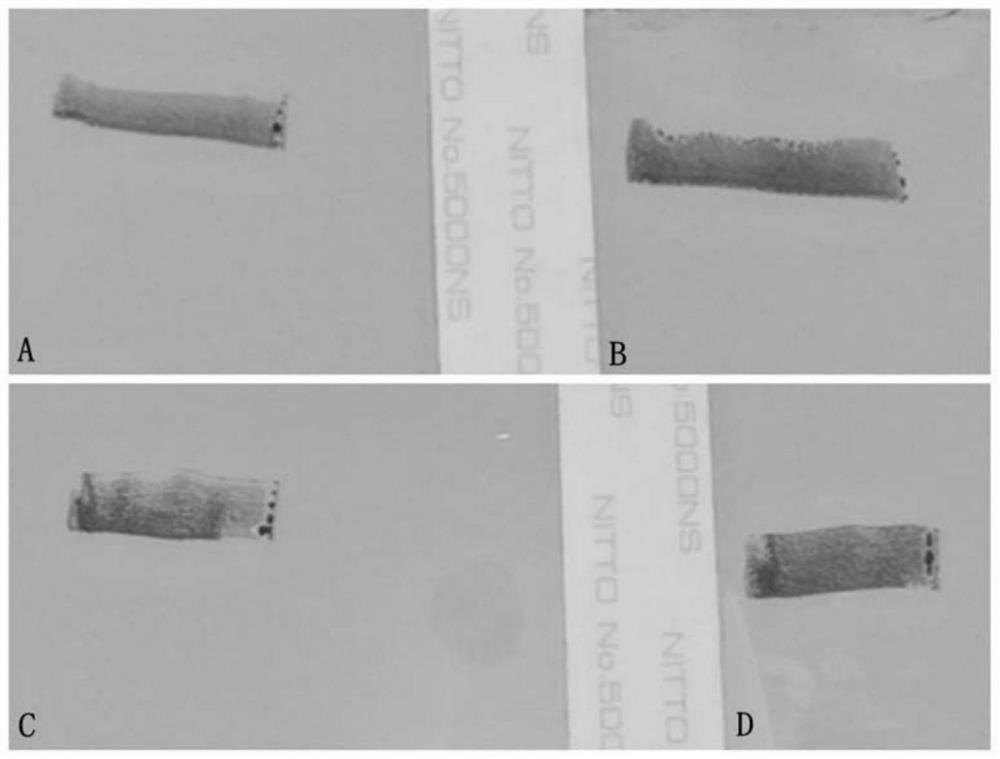

[0065] Examples 1-4 and Comparative Examples 1-2 are samples of the same batch of insulating and heat-conducting silicone gaskets, preforms prepared through step S2 of setting different conditions, and respectively tested Examples 1-4 and The surface tension coefficient (dyne value) of the preform in Comparative Example 1-2.

[0066] The preform surface tension test experiment is as follows: a. Put the cleaned preform flat on the platform; b. Select a group of dyne pens (corona pens) to draw a stroke on the surface of the preform after treatment. Apply basically the same force to the dyne pen, and the length of the ink strips of the dyne strokes on the preform is greater than 4cm; c. Observe that if the pen and ink liquid on the preform does not shrink within 2 to 3 seconds, the preform The processed surface reaches the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com