Combined cast-in-place box girder support system and construction method

A bracket system and combined technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of difficult construction of steel pipe column foundations, heavy work at high altitudes, and increased construction costs, so as to save foundation treatment costs and reduce high altitudes. The effect of large workload and high mechanical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

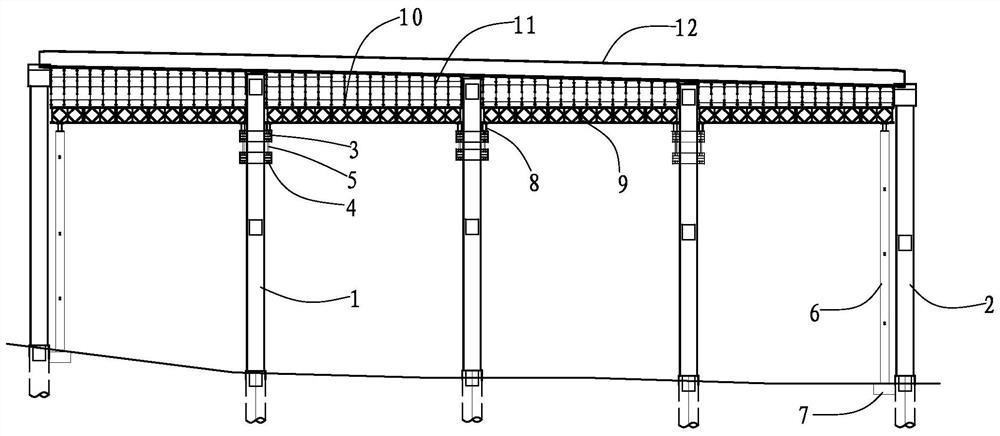

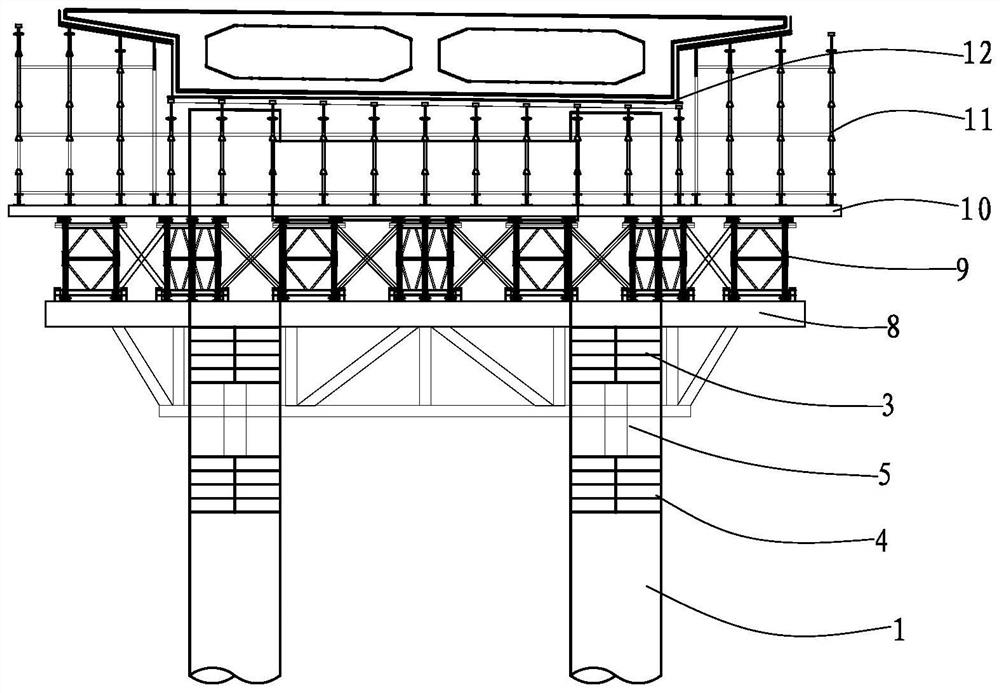

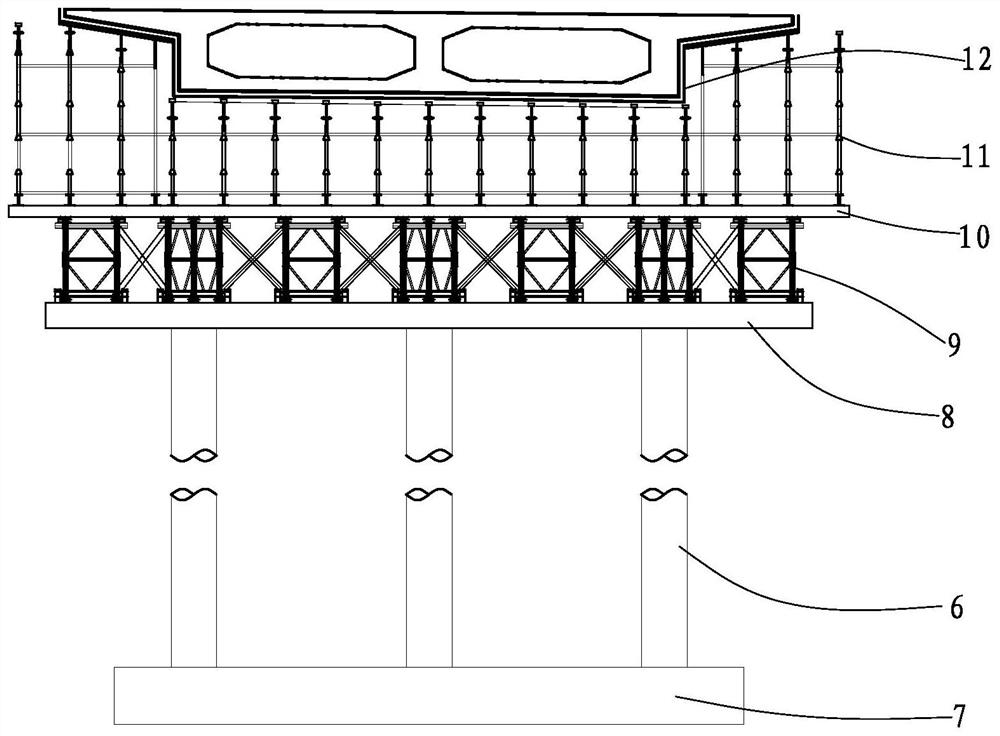

[0023] Such as figure 1 , figure 2 , image 3 As shown, a combined cast-in-place box girder support system provided by the present invention is equipped with an upper hoop 3 and a lower hoop 4 on each mid-span pier 1 of the bridge, and each hoop includes two semicircular There are connecting plates on both sides of the hoop plate, and the two hoop plates are buckled on the pier body. The connecting plates of the two hoop plates are connected by high-strength bolts. The connecting plates of the hoop plates are combined into a hoop corbel; a support rod 5 is provided between the corbels of the upper hoop 2 and the lower hoop 3, and the upper and lower ends of the support rod 5 are connected with the bottom of the upper hoop corbel and the lower hoop respectively. The top of the corbel of the hoop is tight; each side pier 2 of the bridge is respectively provided with a steel pipe column 6, the bottom of the steel pipe column 6 is supported on the ground concrete foundation 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com