Hollow wood panel that can absorb formaldehyde and its internal ventilation structure

A technology for absorbing formaldehyde and wood board, applied in the field of wood board, can solve the problems of pungent odor and low formaldehyde content, and achieve the effects of preventing secondary pollution, reducing the weight of boards and preventing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

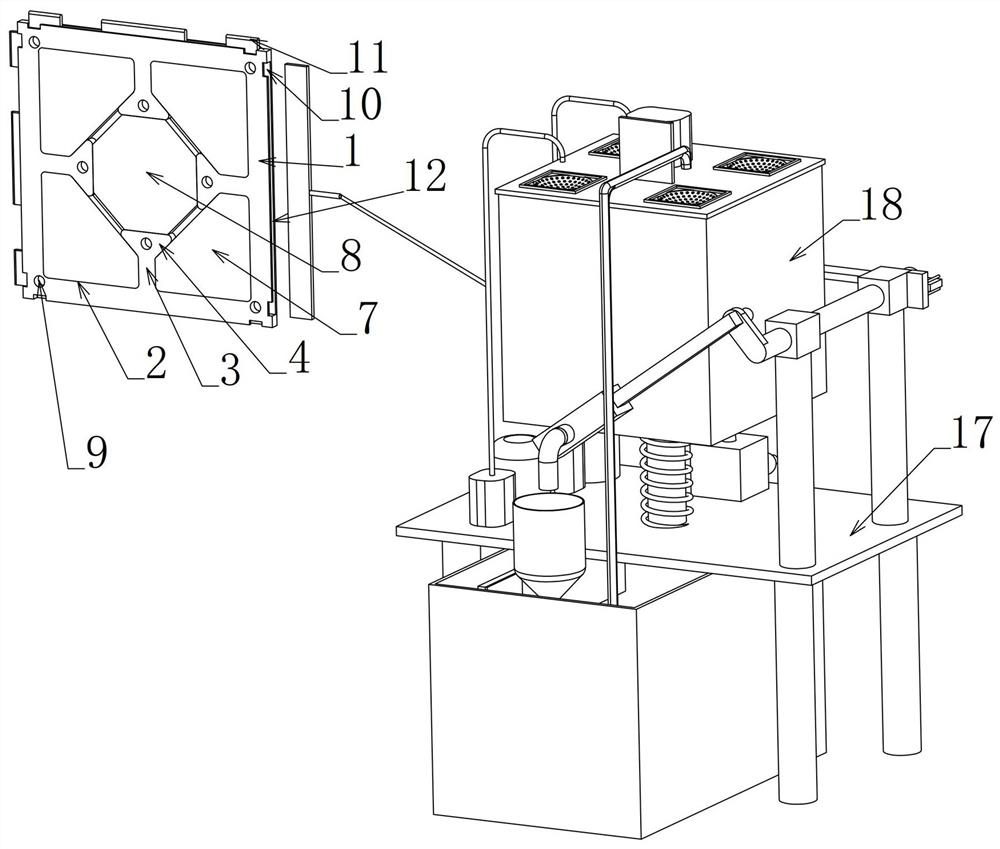

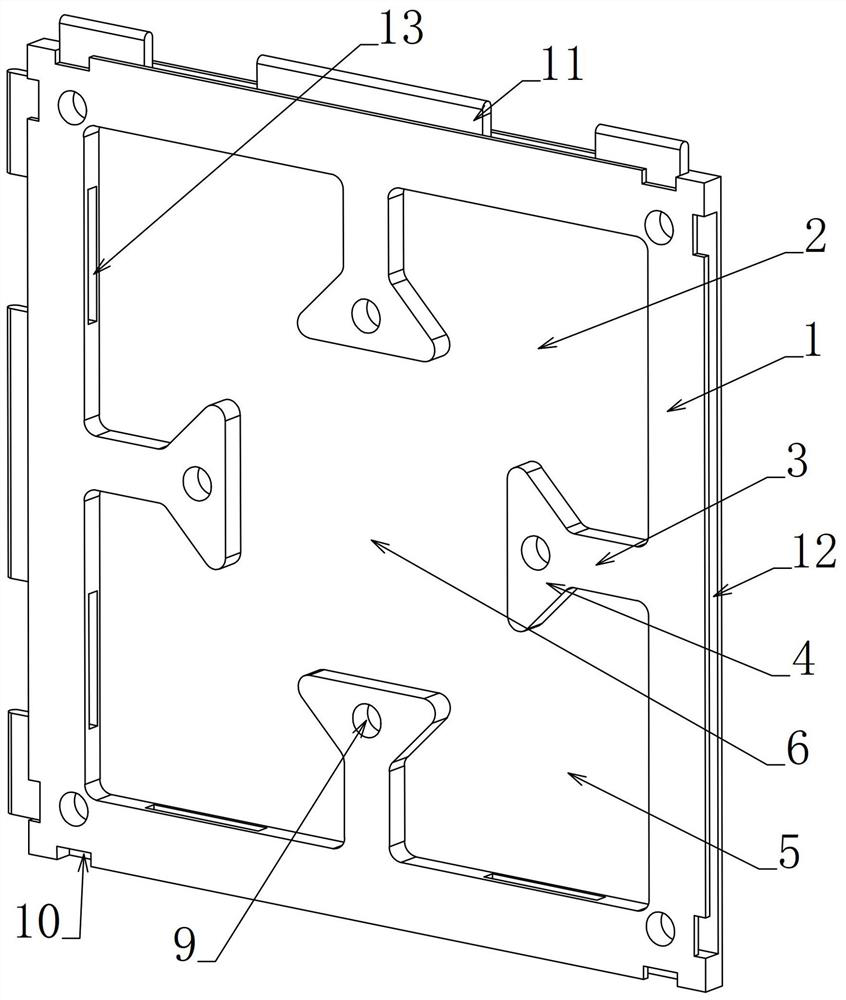

[0057] Embodiment 1, the technical solution it solves is that it is characterized in that it includes a wooden substrate 1, and the front side of the wooden substrate 1 is provided with a square groove 2 that does not pass through backwards, and the upper, lower, left and right sides of the square groove 2 are all A support plate 3 protrudes toward the center of the plank substrate 1, and each support plate 3 is fixedly connected with a triangular support block 4 at the protruding end of each support plate 3 toward the center of the square groove 2, and each support plate 3 and the triangular support block 4 divide the square groove 2 into A plurality of sound-insulating areas 5, each triangular support block 4 faces the side of the center of the square groove 2 to form a connecting area 6, each sound-insulating area 5 is inlaid with a sound-insulating block 7 corresponding to the shape, and the connecting area 6 is inlaid with a connecting area 6 The activated carbon filter bl...

Embodiment 2

[0059] Embodiment 2, on the basis of Embodiment 1, the drain valve 38 includes a square valve body 39, the square valve body 39 is provided with a longitudinal communication hole 40 having the same size and shape as the drainage pipe, and the valve body is provided with a through communication hole The spool groove 41 of the spool groove 41 is slidingly connected with the spool 42, and the spool 42 is fixedly connected with the push rod 37. The valve body is located in the communication hole and is provided with a tapered stopper, which is located on the front side of the spool 42. There is an unloading groove 43 on the top. When the valve core 42 is pushed into the valve body, the valve core 42 gradually blocks the communication hole until the communication hole is completely blocked. Connecting the longitudinal communication holes 40 allows the liquid in the collection cylinder 18 to flow out through the communication holes, and the disconnected state is restored when the val...

Embodiment 3

[0061] Embodiment 3. On the basis of Embodiment 1, the control device includes a rotary valve 44. A rotary valve core 45 is rotatably connected to the rotary valve core 45. A vertical communication hole 46 through the axis is opened on the rotary valve core 45, which is located at The front and rear sides of the rotating spool 45 are respectively provided with drainage grooves 47 protruding to the right, the second rotating motor 48 that controls the rotating spool 45 to rotate, and the limit rod 49 that limits the rotation angle of the second rotating motor 48 , the delivery pump 50 connected to the right end of the rotary valve 44, the outlet of the delivery pump 50 is connected to the upper end of the collection cylinder 18 through a hose, if the valve core 42 is in the rotary valve 44, if no formaldehyde is detected in the circulation cylinder, then the vertical communication hole 46 It is connected with the circulation cylinder, and the water in the circulation cylinder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com