Wall surface spraying machinery and operating equipment

A technology of machinery and paint boxes, applied in the fields of filtration and separation, chemical instruments and methods, construction, etc., can solve the problems of easy clogging of nozzles, inability to dry, easy adhesion of dust, etc., and achieve good retention effect and avoid condensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

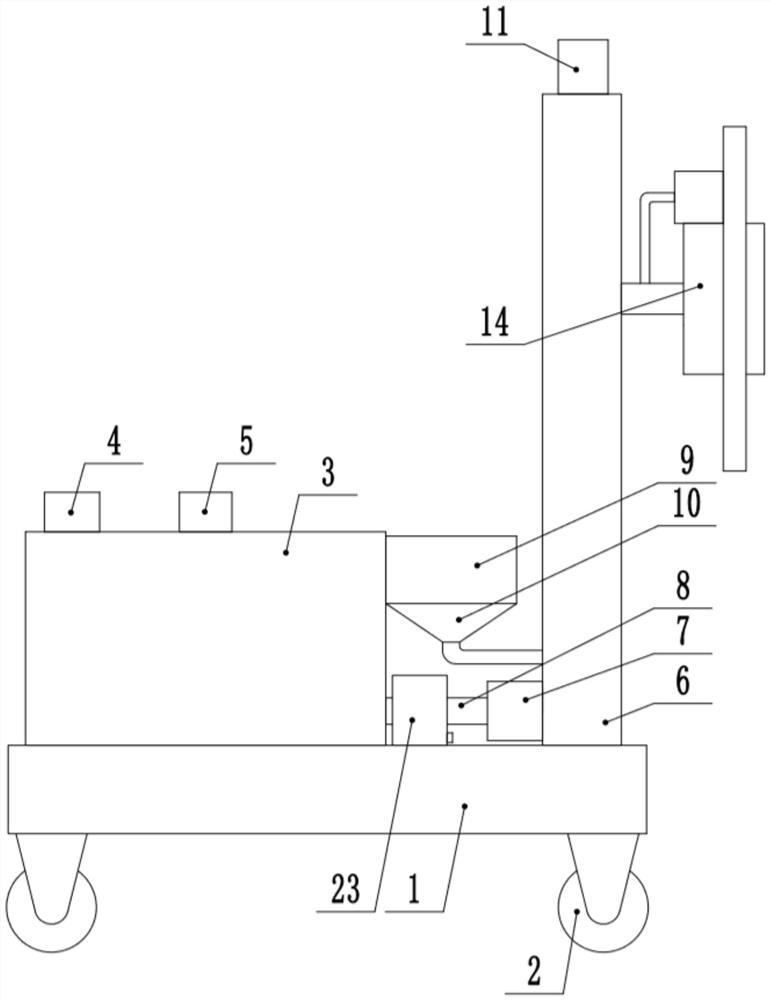

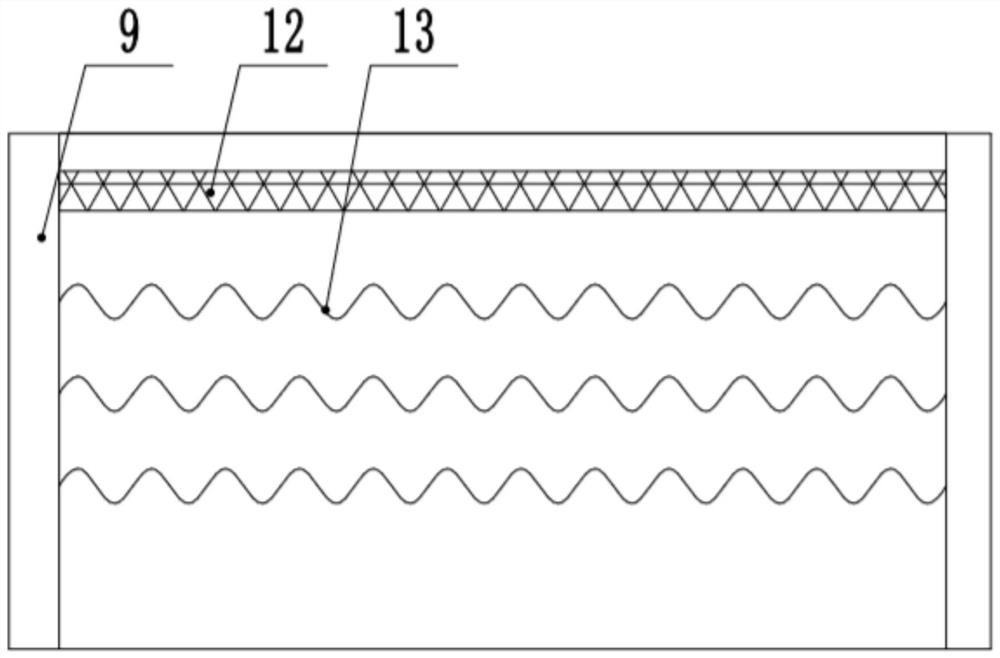

[0024] see Figure 1-5 , a wall spraying machine, comprising a bottom plate 1, the four corners of the bottom of the bottom plate 1 are fixed with roommate moving wheels 2, the top end of the bottom plate 1 is fixedly connected to the paint box 3, and the top end of the paint box 3 is fixedly provided with a feed hopper 4 , the top of the paint tank 3 is fixedly connected to the stirring motor 5, the output shaft of the stirring motor 5 passes through the paint tank 3 and is fixedly connected to the stirring rod, the other end of the top of the bottom plate 1 is fixedly connected to the lifting frame 6, and the lifting frame 6 is provided with a lifting mechanism. The lifting mechanism is connected to the spraying and drying device 14 , and one side of the paint tank 3 is provided with a hot air device and a filter device 24 .

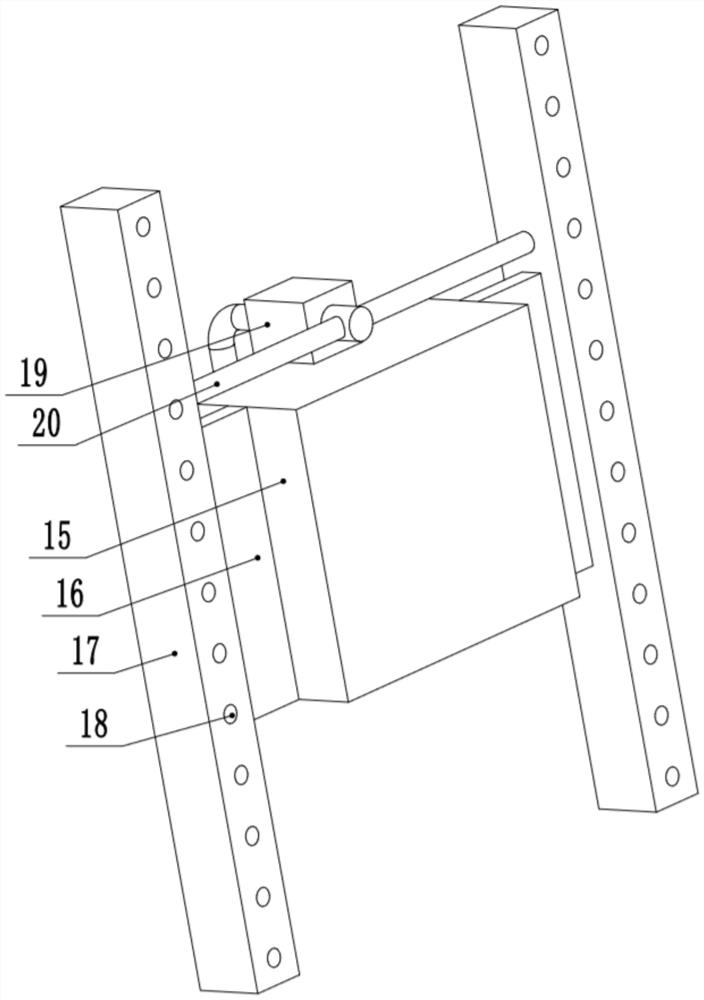

[0025] The lifting mechanism includes a lifting motor 11 fixedly arranged on the top of the lifting frame 6, the output shaft of the lifting motor 11 ...

Embodiment 2

[0030] see Figure 1-5 , a wall spraying machine, comprising a bottom plate 1, the four corners of the bottom of the bottom plate 1 are fixed with roommate moving wheels 2, the top end of the bottom plate 1 is fixedly connected to the paint box 3, and the top end of the paint box 3 is fixedly provided with a feed hopper 4 , the top of the paint tank 3 is fixedly connected to the stirring motor 5, the output shaft of the stirring motor 5 passes through the paint tank 3 and is fixedly connected to the stirring rod, the other end of the top of the bottom plate 1 is fixedly connected to the lifting frame 6, and the lifting frame 6 is provided with a lifting mechanism. The lifting mechanism is connected to the spraying and drying device 14 , and one side of the paint tank 3 is provided with a hot air device and a filter device 24 .

[0031] The lifting mechanism includes a lifting motor 11 fixedly arranged on the top of the lifting frame 6, the output shaft of the lifting motor 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com