Efficient heat supply system arranged in secondary reheating unit

A technology for secondary reheating and heating systems, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of temperature reduction and pressure loss, unfavorable control of boiler reheating steam temperature, low efficiency of small steam turbines, etc. , to alleviate the under-temperature problem, facilitate the stability of reheat steam temperature regulation, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

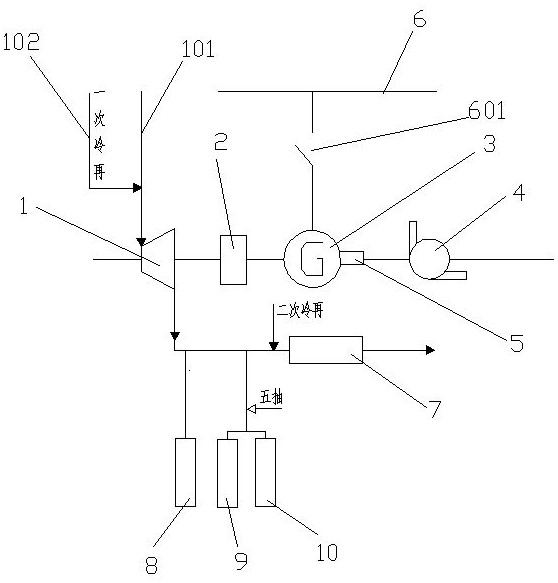

[0016] Such as figure 1 As shown, the present invention proposes a high-efficiency heating system placed in the secondary reheating unit. Heating economy, at the same time, excess kinetic energy can be converted into electrical energy, reducing the power consumption rate of the factory.

[0017] A high-efficiency heating system placed in a double reheating unit is characterized in that it includes a small steam turbine 1, a clutch gearbox 2, an electric motor / generator 3, and an induced draft fan 4. The small steam turbine 1 adopts a back-pressure steam turbine. The steam inlet source 101 of the small steam turbine is extracted from the outlet of the first-stage reheater reheater of the power plant boiler, and the temperature-adjusted steam source 102 is taken from the inlet of the first-stage reheater reheater ( That is, as shown in the figure once cold again). The rotating shaft of the small steam turbine 1 is connected to the clutch gearbox 2, one side of the clutch gearb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com