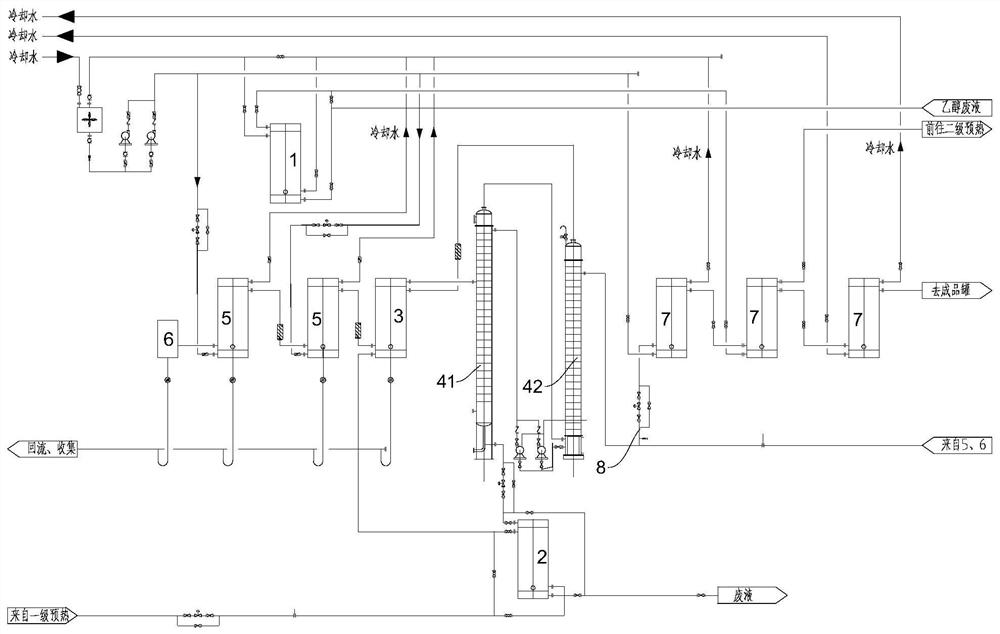

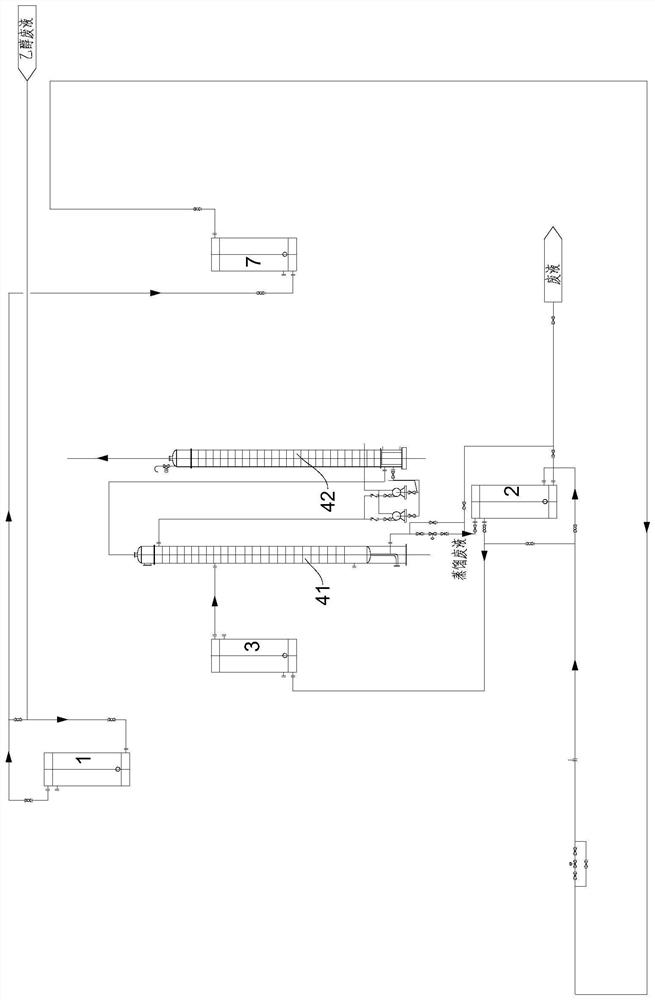

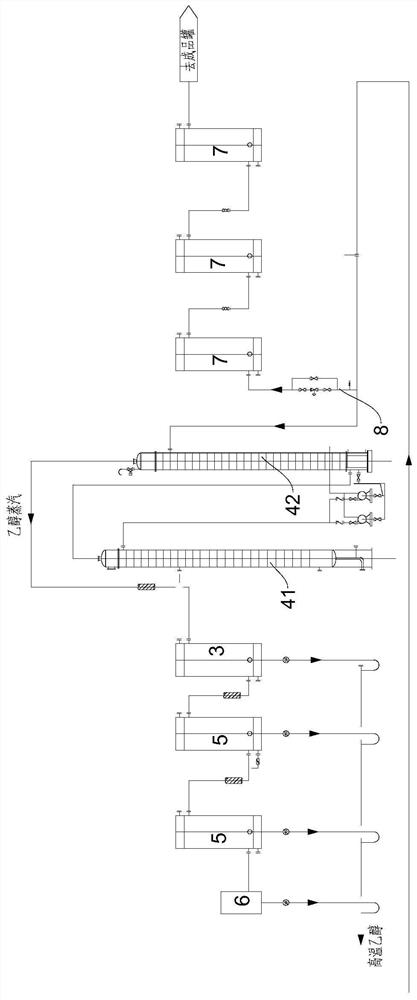

Boiling liquid heat exchange energy-saving system for ethanol recovery

A heat exchange energy-saving, ethanol technology, applied in the direction of distillation energy recovery, heating water/sewage treatment, special treatment goals, etc., can solve the problems of energy waste and high cost, and achieve the effect of reduced use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it.

[0020] A number of different implementations or examples of implementing the described subject technical solutions are disclosed below. In order to simplify the disclosure, the following describes specific embodiments of one or more permutations of each feature, but the examples cited are not intended to limit the present invention, and the first feature described later in the specification is connected to the second feature, namely It may include the embodiment of direct connection, and may also include the embodiment of forming additional features. Further, it also includes the use of one or more other intervening features to indirectly communicate or combine the first feature and the second feature with each other, so that the first feature and The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com