A reversible phase-change atomized liquid gel comprising a hydrocarbon-aryl-glycosyl three-stage sugar-based gelling agent and its preparation method and application

A technology for atomizing liquid and gelling agent, applied in the field of atomized liquid gel and its preparation, can solve the problems of complex preparation process, leakage of smoke liquid, complex structure and manufacturing process, etc. Hydrophobic interaction, effect of stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

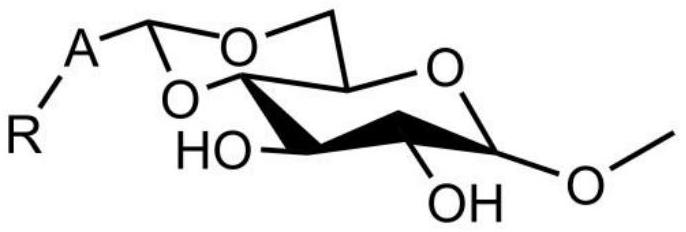

Image

Examples

Embodiment 1

[0053] This embodiment is an atomized liquid gel 1 with thermally reversible phase change characteristics, which includes: sugar-based gelling agent, 0.8wt%; atomized liquid, 99.2wt%; based on the mass percentage of the atomized liquid, the The atomized liquid includes: an atomizing agent, which accounts for 92.0 wt% of the atomized liquid; nicotine, which accounts for 2.0 wt% of the atomized liquid; spices, which accounts for 6.0 wt% of the atomized liquid; The atomizer is a mixture of glycerin and propylene glycol, wherein the volume ratio of glycerin and propylene glycol is 5:5.

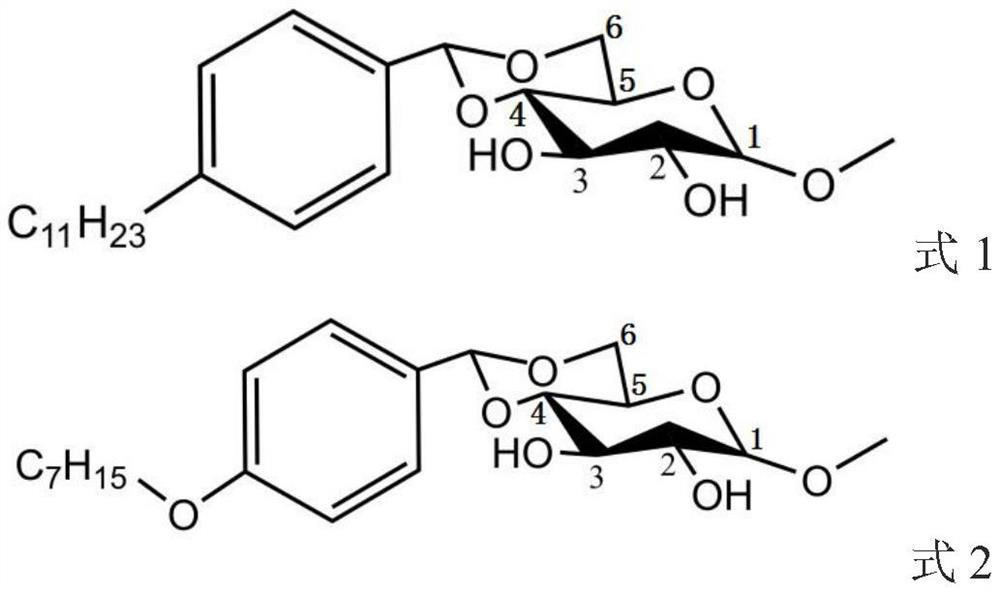

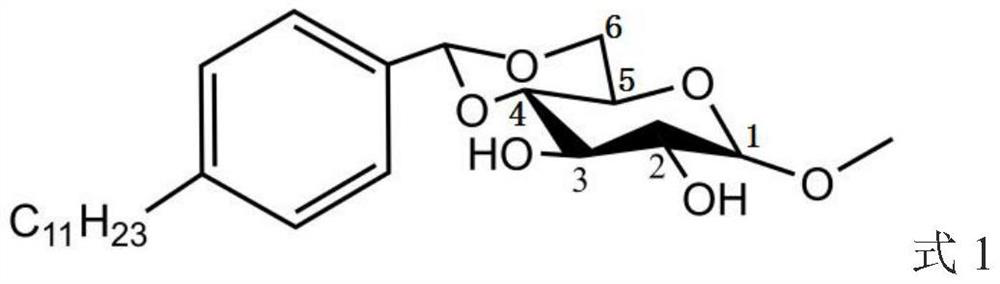

[0054] The chemical structural formula of the sugar-based gelling agent is:

[0055]

[0056] Directly inject the molten atomizing liquid gel 1 solution of this embodiment into the liquid storage chamber of the electronic cigarette atomizer, and after the solution is cooled and gelled, the atomizing liquid gel cartridge 1 suitable for electronic cigarettes is prepared, and the For electronic c...

Embodiment 2

[0059] This embodiment is an atomized liquid gel 2 with shear reversible phase transition characteristics, and the chemical structural formula of the sugar-based gelling agent used in it is:

[0060]

[0061] Other preparation conditions, the distribution ratio of each component are the same as in Example 1.

[0062] Directly inject the molten atomized liquid gel 1 solution of this example into the liquid storage tank of the atomizer, and after the solution is cooled and gelled, the atomized liquid gel pod 1 is prepared, which is used for high-frequency bulk acoustic wave In the oscillating atomization device, the critical shear stress of the gel-sol phase transition is 185Pa. Under high shear and violent oscillation (sonic frequency 2.4MHz), the gel network structure is destroyed, the gel viscosity decreases, and the trapped The atomized liquid is released to produce an inhalable aerosol; after a few puffs, the vibration is stopped, and the gel can be quickly self-assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com